Are you gearing up for a career in Airframe and Powerplant Mechanic (A and P Mechanic)? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Airframe and Powerplant Mechanic (A and P Mechanic) and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

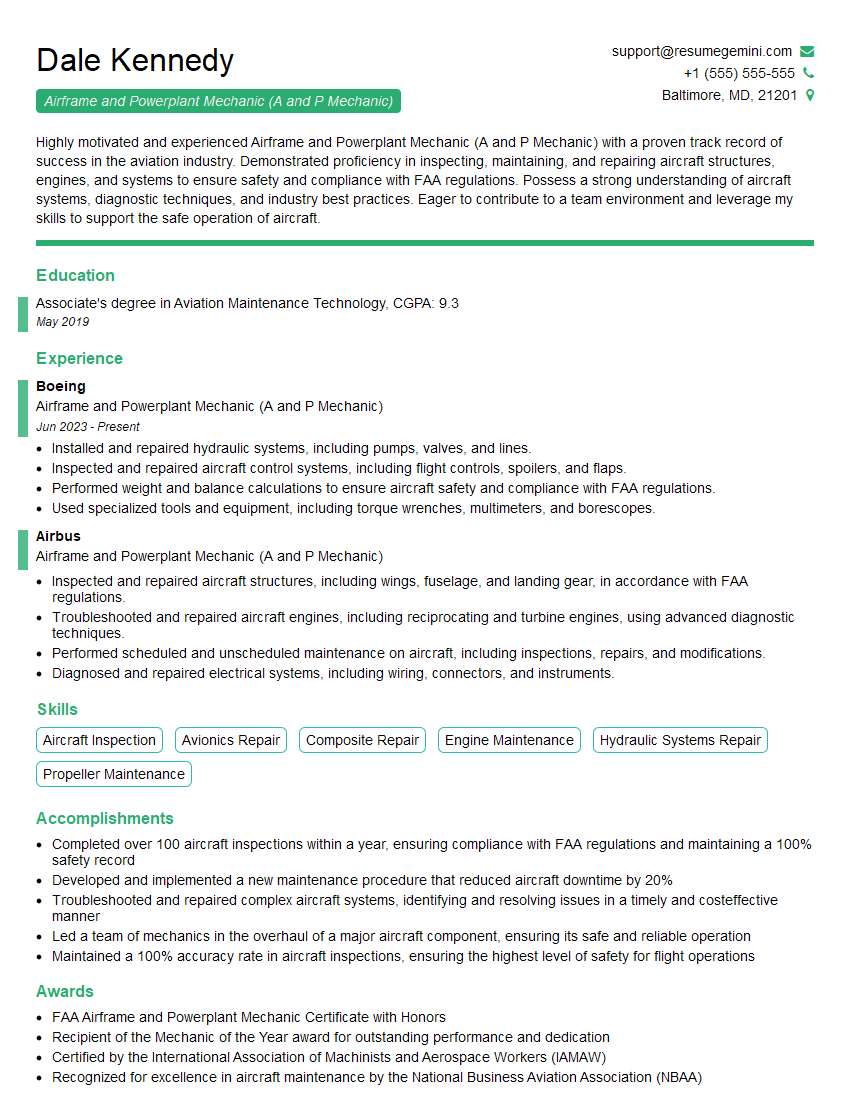

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Airframe and Powerplant Mechanic (A and P Mechanic)

1. Describe the steps involved in troubleshooting an electrical system on an aircraft.

- Gather information about the problem, including symptoms and any recent maintenance or repairs.

- Inspect the electrical system for any obvious damage or loose connections.

- Use a multimeter or other test equipment to measure voltage, amperage, and resistance in the electrical system.

- Analyze the test results to identify the source of the problem.

- Repair or replace the faulty component or connection.

- Test the electrical system to ensure that the problem has been resolved.

2. How do you inspect an aircraft engine for wear and tear?

subheading of the answer

- Visually inspect the engine for any signs of wear, damage, or corrosion.

- Use a borescope to inspect the interior of the engine for any signs of wear or damage.

- Measure the compression in each cylinder to check for any signs of wear or damage.

- Listen to the engine while it is running for any unusual noises that may indicate a problem.

subheading of the answer

- Use a vibration analyzer to measure the vibration levels in the engine to check for any signs of imbalance or wear.

- Use an oil analysis to check for any signs of wear or contamination in the engine oil.

- Inspect the engine logs to review any maintenance or repairs that have been performed on the engine.

3. What are the different types of aircraft landing gear systems and how do they work?

- Fixed landing gear: This type of landing gear is permanently attached to the aircraft and cannot be retracted. It is typically used on small aircraft and provides a simple and reliable landing system.

- Retractable landing gear: This type of landing gear can be retracted into the aircraft’s fuselage or wings when not in use. This reduces drag and improves the aircraft’s aerodynamic performance. Retractable landing gear is typically used on larger aircraft.

- Trailing link landing gear: This type of landing gear is designed to absorb shock and vibration during landing and takeoff. It is typically used on large aircraft and provides a smooth and comfortable ride for passengers.

- Nosewheel landing gear: This type of landing gear is used on aircraft that have a tricycle landing gear configuration. The nosewheel provides steering and stability during ground operations.

4. How do you maintain and repair aircraft hydraulic systems?

- Inspect the hydraulic system for any leaks, damage, or contamination.

- Replace any damaged or worn components.

- Flush the hydraulic system to remove any contaminants.

- Replenish the hydraulic fluid to the correct level.

- Test the hydraulic system to ensure that it is functioning properly.

5. What are the different types of aircraft fuel systems and how do they work?

- Gravity-fed fuel system: This type of fuel system uses gravity to deliver fuel from the fuel tanks to the engine. It is typically used on small aircraft and is simple and reliable.

- Pressure-fed fuel system: This type of fuel system uses a fuel pump to deliver fuel from the fuel tanks to the engine. It is typically used on larger aircraft and provides a more consistent fuel flow.

- Fuel-injected fuel system: This type of fuel system uses a fuel injector to spray fuel directly into the engine’s cylinders. It is typically used on high-performance aircraft and provides the most efficient fuel delivery.

6. How do you maintain and repair aircraft electrical systems?

- Inspect the electrical system for any damage, corrosion, or loose connections.

- Test the electrical system to ensure that it is functioning properly.

- Replace any damaged or worn components.

- Clean and lubricate electrical connectors.

- Inspect and maintain the aircraft’s battery.

7. What are the different types of aircraft flight controls and how do they work?

- Ailerons: These control surfaces are located on the trailing edge of the wings and are used to roll the aircraft.

- Elevators: These control surfaces are located on the trailing edge of the horizontal stabilizer and are used to pitch the aircraft.

- Rudder: This control surface is located on the trailing edge of the vertical stabilizer and is used to yaw the aircraft.

- Flaps: These control surfaces are located on the trailing edge of the wings and are used to increase the lift and drag of the aircraft.

- Slats: These control surfaces are located on the leading edge of the wings and are used to increase the lift of the aircraft.

8. How do you maintain and repair aircraft composite structures?

- Inspect the composite structure for any damage or delamination.

- Repair any damage using the appropriate repair techniques.

- Clean and protect the composite structure from the elements.

- Inspect and maintain the aircraft’s composite fasteners.

9. What are the different types of aircraft inspection programs and how are they conducted?

- Daily inspection: This inspection is performed before each flight and is used to check for any obvious damage or problems with the aircraft.

- Weekly inspection: This inspection is performed weekly and is used to check for any signs of wear or tear on the aircraft.

- Monthly inspection: This inspection is performed monthly and is used to check for any major problems with the aircraft.

- Annual inspection: This inspection is performed annually and is used to check for any major problems with the aircraft and to ensure that it is airworthy.

10. What are the different types of aircraft maintenance manuals and how are they used?

- Airworthiness Directives (ADs): These manuals provide instructions for the maintenance and repair of aircraft that have been issued by the Federal Aviation Administration (FAA) to address safety concerns.

- Service Bulletins (SBs): These manuals provide instructions for the maintenance and repair of aircraft that have been issued by the aircraft manufacturer to address known problems.

- Overhaul Manuals: These manuals provide instructions for the overhaul of aircraft components and systems.

- Repair Manuals: These manuals provide instructions for the repair of aircraft components and systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Airframe and Powerplant Mechanic (A and P Mechanic).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Airframe and Powerplant Mechanic (A and P Mechanic)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Airframe and Powerplant Mechanics, also known as A and P Mechanics, play a crucial role in maintaining the safety and airworthiness of aircraft. Their primary responsibilities encompass a wide range of tasks, including:

1. Aircraft Maintenance and Inspection

Performing regular inspections, checks, and repairs on aircraft structures, components, and systems, ensuring compliance with aviation regulations and safety standards.

- Inspecting and repairing airframes, engines, propellers, hydraulics, electrical systems, and avionics.

- Conducting preventive maintenance, such as lubrication, adjustments, and corrosion control.

2. Troubleshooting and Repair

Diagnosing and resolving technical issues, performing repairs and replacements as needed to restore aircraft to optimal operating condition.

- Identifying and locating the root cause of malfunctions and defects.

- Using specialized tools and equipment to service and repair aircraft.

3. Documentation and Record Keeping

Maintaining accurate records of all maintenance activities, including inspection reports, repairs performed, and parts replaced, ensuring compliance with federal regulations.

- Completing logbooks, work orders, and maintenance manuals.

- Adhering to quality control procedures and documenting all findings.

4. Communication and Teamwork

Collaborating with pilots, engineers, and other aircraft personnel to ensure efficient maintenance and operations.

- Providing technical advice and support on maintenance issues.

- Working as part of a team to ensure timely completion of maintenance tasks.

Interview Tips

Preparing for an interview for an A and P Mechanic position requires thorough research and a strategic approach. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, culture, and the specific requirements of the A and P Mechanic position. This will demonstrate your interest in the role and your ability to align with the company’s needs.

- Visit the company’s website and social media pages.

- Read industry publications and news articles to stay updated on the latest aviation trends.

2. Highlight Your Skills and Experience

Quantify your accomplishments and emphasize your relevant skills, such as aircraft maintenance, troubleshooting, and repair. Use specific examples to showcase your abilities and how they align with the job requirements.

- Describe a complex repair you successfully completed.

- Share a situation where you used your problem-solving skills to resolve a technical issue.

3. Demonstrate Your Commitment to Safety

Safety is paramount in aviation maintenance. Emphasize your understanding of safety regulations and your commitment to adhering to them. Discuss your experience in conducting thorough inspections and following proper maintenance procedures.

- Explain your understanding of FARs (Federal Aviation Regulations) and other safety guidelines.

- Describe a situation where you identified a potential safety hazard and took appropriate action.

4. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions that demonstrate your knowledge of the industry and your desire to learn more about the company.

- Inquire about the company’s safety culture and maintenance practices.

- Ask about opportunities for professional development and training.

5. Practice and Preparation

Practice answering common interview questions aloud or with a mock interviewer. This will build your confidence and allow you to refine your responses.

- Prepare an elevator pitch that highlights your skills and qualifications.

- Dress professionally and arrive punctually for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Airframe and Powerplant Mechanic (A and P Mechanic) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!