Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Airframe and Powerplant Mechanic Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

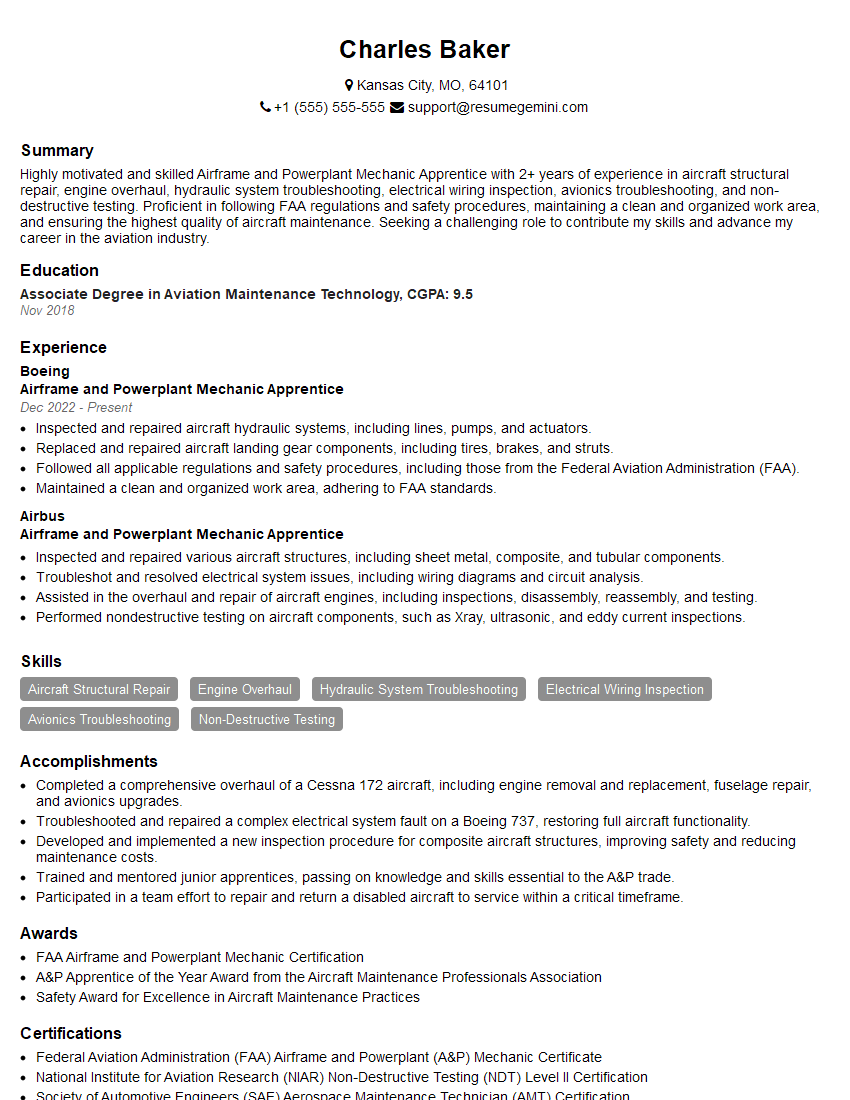

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Airframe and Powerplant Mechanic Apprentice

1. Explain the process of troubleshooting an electrical system on an aircraft?

To begin troubleshooting, gather the necessary information and tools. Check the aircraft manuals for troubleshooting charts and isolate the problem to a specific system or component.

- Identify the affected systems and components.

- Check for loose connections, broken wires, or damaged components.

- Use a multimeter and other diagnostic tools to measure voltage, current, and resistance.

- Refer to wiring diagrams and schematics to trace the flow of electricity.

- Replace or repair faulty components as necessary.

2. Describe the steps involved in performing a pre-flight inspection of an aircraft?

Inspection Areas

- Check exterior surfaces for dents, cracks, or damage.

- Inspect control surfaces for proper operation and clearances.

- Verify fluid levels, including oil, fuel, and hydraulics.

- Examine tires and brakes for wear or damage.

Documentation

- Record all findings and any discrepancies on the pre-flight inspection form.

- Obtain a signature from the responsible mechanic to certify the inspection.

- Maintain a logbook to track aircraft maintenance and inspections.

3. Explain the importance of proper record-keeping for aircraft maintenance?

- Tracking maintenance history ensures safety by documenting repairs and modifications.

- Warranties and insurance claims require accurate records of maintenance performed.

- Detailed records help identify potential issues and trends, enabling proactive maintenance.

- Records serve as evidence of compliance with regulations and standards.

- Proper documentation improves communication and collaboration among maintenance teams.

4. Describe the role of non-destructive testing (NDT) in aircraft maintenance?

- NDT techniques allow us to inspect aircraft components without causing damage.

- Methods include visual inspection, ultrasonic testing, and eddy current testing.

- NDT helps detect hidden defects, such as cracks, corrosion, or other anomalies.

- Regular NDT inspections enhance safety by identifying potential failures before they become critical.

- NDT contributes to cost savings by extending the lifespan of components and reducing the need for major repairs.

5. Discuss the safety precautions that must be followed when working on aircraft?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures to prevent accidental activation or movement of aircraft components.

- Use proper tools and equipment for each task, ensuring they are in good working condition.

- Be aware of potential hazards, such as electrical wires, rotating propellers, and flammable materials.

- Maintain a clean and organized work area to minimize tripping or other accidents.

6. Describe the different types of aircraft structures and materials?

- Monocoque structure: Stressed skin design where the aircraft skin carries most of the loads.

- Semi-monocoque structure: Combines a stressed skin with additional internal support structures.

- Truss structure: Uses a framework of beams and struts to support the aircraft.

- Materials used: Aluminum alloys, titanium alloys, composite materials, and steel.

- Specific material properties: Strength-to-weight ratio, corrosion resistance, and durability.

7. Explain the importance of balancing propellers on an aircraft?

- Reduced vibration: Balanced propellers cause minimal vibration, enhancing passenger comfort and reducing fatigue on aircraft components.

- Increased efficiency: Balanced propellers operate more efficiently, saving fuel and improving performance.

- Extended lifespan: Proper balancing reduces stress on the propeller and other aircraft systems, extending their lifespan.

- Compliance with regulations: Balancing propellers is required by aviation regulations to ensure safe operation.

8. Discuss the different methods used to repair aircraft composite structures?

- Wet layup: Applying layers of composite material with resin.

- Prepreg layup: Using pre-impregnated composite material.

- Vacuum bagging: Applying vacuum to remove excess resin and improve bonding.

- Autoclave curing: Using an autoclave to apply heat and pressure for curing.

- Localized heating: Using heat guns or induction heating to repair specific areas.

9. Describe the function and operation of an aircraft hydraulic system?

- Function: Transmits power from the engine or an auxiliary power unit to control aircraft systems, such as landing gear, flaps, and brakes.

- Components: Includes hydraulic pumps, reservoirs, valves, actuators, and lines.

- Operation: Hydraulic fluid is pumped from the reservoir to the actuators, which convert hydraulic pressure into mechanical motion.

- Maintenance: Involves monitoring fluid levels, checking for leaks, and replacing filters and seals as needed.

10. Discuss the importance of following maintenance manuals and instructions when working on aircraft?

- Safety: Manuals provide critical information to ensure safe maintenance practices.

- Compliance: Following instructions ensures compliance with aviation regulations and industry standards.

- Efficiency: Manuals streamline maintenance procedures, saving time and resources.

- Accuracy: Instructions provide precise steps to complete tasks correctly.

- Liability: Adhering to manuals reduces the risk of legal liability in case of accidents or incidents.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Airframe and Powerplant Mechanic Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Airframe and Powerplant Mechanic Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Airframe and Powerplant Mechanic Apprentice works under the supervision of an experienced mechanic and is responsible for assisting in the maintenance, repair, and inspection of aircraft and their components.

1. Maintenance and Repair

Assists in performing scheduled and unscheduled maintenance and repairs on airframes, engines, and aircraft systems.

- Inspects and replaces worn or damaged parts, such as rivets, seals, and gaskets.

- Repairs and adjusts mechanical and electrical systems, such as fuel systems, hydraulic systems, and electrical wiring.

2. Component Inspection

Conducts inspections on aircraft components, such as wings, fuselage, landing gear, and engines.

- Uses visual inspection techniques to identify any cracks, corrosion, or other damage.

- Reports any defects or anomalies to the supervising mechanic for further evaluation.

3. Testing and Calibration

Assists in testing and calibrating aircraft systems and components.

- Performs operational checks on electrical systems, hydraulic systems, and fuel systems.

- Adjusts and calibrates instruments and sensors to ensure accurate readings.

4. Documentation

Maintains accurate and detailed records of all maintenance and repair activities.

- Creates work orders, inspection reports, and maintenance logs.

- Ensures that all documentation meets industry standards and regulations.

Interview Preparation Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace the interview for an Airframe and Powerplant Mechanic Apprentice position:

1. Research the Company and Position

Take the time to learn about the company and the specific responsibilities of the Airframe and Powerplant Mechanic Apprentice role. Visiting the company’s website, reading industry publications, and networking with professionals in the field can provide valuable insights.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Practice answering questions about your technical skills, experience in aircraft maintenance, and knowledge of industry regulations. You may also encounter behavioral questions, so be prepared to provide examples of your teamwork, problem-solving abilities, and attention to detail.

3. Highlight Your Relevant Skills and Experience

Emphasize your skills and experience that align with the job requirements. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact. For example, instead of saying “I inspected aircraft components,” you could say “I conducted visual inspections on over 100 aircraft components daily, identifying and reporting any defects to ensure safe operation.”

4. Dress Professionally and Arrive Punctually

First impressions matter, so dress professionally for the interview and arrive on time. Your appearance and punctuality will not only demonstrate respect for the interviewer but also indicate your attention to detail and commitment to the role.

5. Be Enthusiastic and Ask Insightful Questions

Convey your enthusiasm for the opportunity and the field of aircraft maintenance. Asking insightful questions at the end of the interview shows that you are engaged and interested in learning more. It also provides you with an opportunity to clarify any aspects of the role or the company.

Next Step:

Now that you’re armed with the knowledge of Airframe and Powerplant Mechanic Apprentice interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Airframe and Powerplant Mechanic Apprentice positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini