Are you gearing up for an interview for a Airframe and Powerplant Technician (A and P Technicians) position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Airframe and Powerplant Technician (A and P Technicians) and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

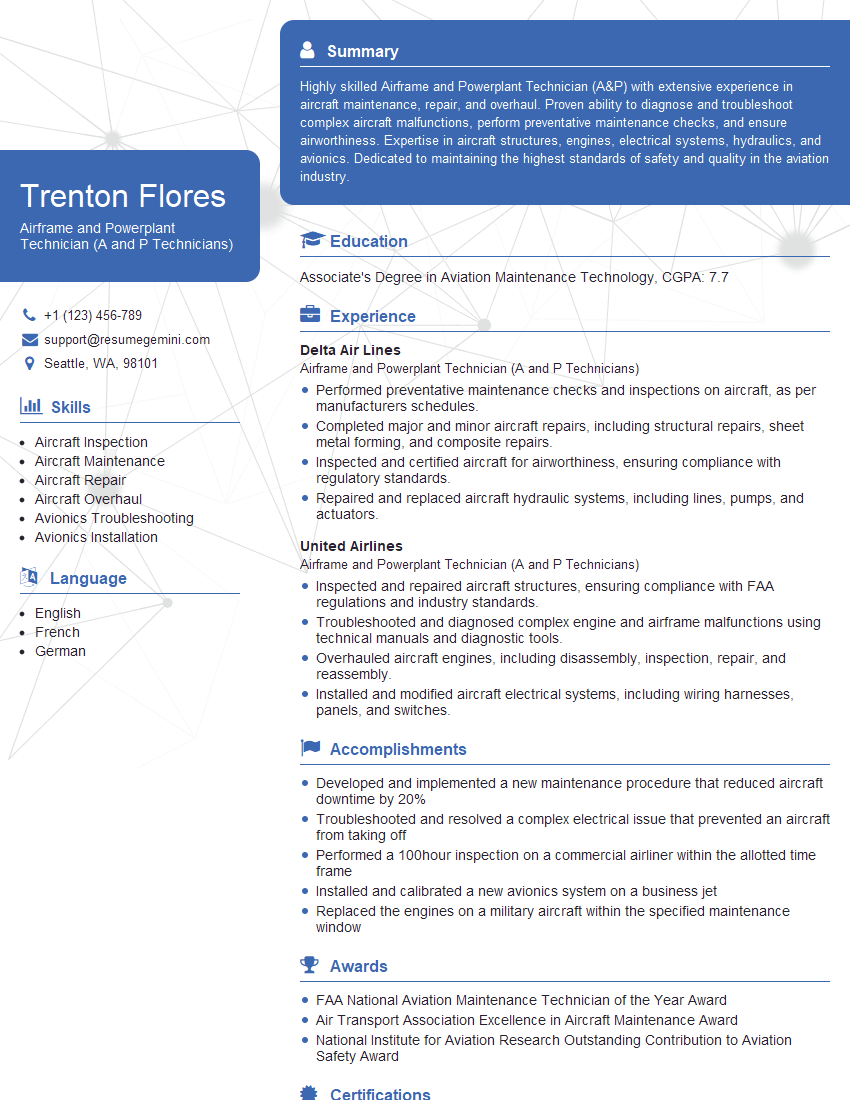

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Airframe and Powerplant Technician (A and P Technicians)

1. Describe the process of troubleshooting an electrical system on an aircraft.

- Start by visually inspecting the system for any loose wires or connections.

- Use a multimeter to test the voltage and continuity of the circuit.

- Isolate the fault by disconnecting each component in the circuit until the fault is found.

- Repair or replace the faulty component and reassemble the system.

- Test the system to ensure that it is functioning properly.

2. How would you inspect an aircraft’s landing gear?

subheading of the answer

- Check the tires for wear and tear.

- Inspect the brakes for any signs of damage or wear.

- Check the hydraulic lines for any leaks or damage.

- Operate the landing gear to ensure that it is functioning properly.

subheading of the answer

- Check the landing gear for any signs of corrosion or damage.

- Inspect the landing gear struts for any leaks or damage.

- Check the landing gear doors for any damage or misalignment.

3. What are the different types of aircraft engines and how do they work?

- Reciprocating engines use pistons to convert the linear motion of the pistons into rotary motion to power the aircraft.

- Turbine engines use a compressor to compress air, which is then mixed with fuel and burned in a combustion chamber. The hot gases then expand through a turbine, which drives the compressor and the aircraft’s propeller or fan.

- Rocket engines use the combustion of fuel to create hot gases that are expelled through a nozzle, which provides thrust to the aircraft.

4. How would you troubleshoot an engine that is not starting?

- Check the battery for voltage and connections.

- Check the spark plugs for wear or damage.

- Check the fuel system for leaks or blockages.

- Check the ignition system for any faults.

- Check the engine compression for any loss of compression.

5. What are the different types of aircraft structures and how are they constructed?

- Monocoque structures are made of a single skin that is stressed to carry the aircraft’s loads.

- Semi-monocoque structures are made of a skin that is supported by a framework of spars and ribs.

- Truss structures are made of a network of trusses that carry the aircraft’s loads.

6. How would you inspect an aircraft’s composite structure?

- Visually inspect the composite structure for any cracks, delaminations, or other damage.

- Use a tap hammer to test the composite structure for any soft spots or voids.

- Use an ultrasonic testing device to inspect the composite structure for any internal defects.

7. What are the different types of aircraft hydraulic systems and how do they work?

- Open-center hydraulic systems use a pump to circulate hydraulic fluid through the system continuously.

- Closed-center hydraulic systems use a pump to circulate hydraulic fluid only when it is needed.

- Electro-hydraulic systems use an electric motor to drive a hydraulic pump.

8. How would you troubleshoot a hydraulic system that is not working properly?

- Check the hydraulic fluid for leaks or contamination.

- Check the hydraulic pump for any leaks or damage.

- Check the hydraulic lines for any leaks or damage.

- Check the hydraulic actuators for any leaks or damage.

9. What are the different types of aircraft electrical systems and how do they work?

- DC electrical systems use a battery to provide electrical power to the aircraft.

- AC electrical systems use an alternator to generate electrical power to the aircraft.

- Hybrid electrical systems use a combination of DC and AC electrical systems.

10. How would you troubleshoot an electrical system that is not working properly?

- Check the battery for voltage and connections.

- Check the alternator for any leaks or damage.

- Check the electrical lines for any leaks or damage.

- Check the electrical components for any faults.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Airframe and Powerplant Technician (A and P Technicians).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Airframe and Powerplant Technician (A and P Technicians)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Airframe and Powerplant (A and P) Technicians play a crucial role in ensuring the safety and maintenance of aircraft, maintaining the flightworthiness of aircraft and components, and diagnosing, repairing, and overhauling various aircraft systems.

1. Inspection, Maintenance, and Repair

A and P Technicians conduct thorough inspections, maintenance, and repairs on aircraft structures, such as airframes, fuselages, and landing gear. They also inspect, maintain, and repair aircraft engines, including turbines, pistons, and propellers.

- Inspecting and repairing aircraft structures for damage, corrosion, and wear

- Installing and replacing components, such as engines, wings, and landing gear

- Performing scheduled maintenance and repairs according to aircraft maintenance manuals

2. Troubleshooting and Diagnosis

A and P Technicians diagnose and troubleshoot aircraft malfunctions using diagnostic tools and equipment. They determine the root cause of problems and take appropriate corrective actions to ensure the aircraft’s safe and reliable operation.

- Diagnosing aircraft malfunctions through ground tests, flight tests, and data analysis

- Troubleshoot and repair electrical, hydraulic, and mechanical systems

- Inspecting and testing aircraft systems to ensure proper operation

3. Recordkeeping and Documentation

A and P Technicians maintain accurate records and documentation of all aircraft maintenance and repairs. This includes log books, maintenance reports, and inspection checklists. The documentation ensures that the aircraft meets regulatory and safety standards.

- Maintaining aircraft maintenance records, including repair logs and inspection reports

- Documenting all maintenance activities performed on aircraft

- Completing required paperwork and ensuring compliance with regulatory requirements

4. Compliance with Regulations

A and P Technicians are responsible for ensuring that aircraft maintenance, repair, and overhaul activities comply with industry standards and regulatory requirements. They must stay up-to-date with aviation regulations and best practices.

- Adhering to FAA regulations, industry standards, and maintenance manuals

- Staying informed about aviation safety updates and technical advancements

- Obtaining and maintaining required certifications and licenses

Interview Tips

Preparing thoroughly for an Airframe and Powerplant Technician interview can significantly increase your chances of success. Here are some useful tips and tricks:

1. Research the Company and Position

Before the interview, take the time to research the company, the specific position you are applying for, and the industry as a whole. This will demonstrate your interest in the role and help you understand the company’s values and culture.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Identify the company’s competitors and market position

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the actual interview.

- Why are you interested in this position?

- Tell me about your experience in aircraft maintenance and repair.

- What are your strengths and weaknesses as an A and P Technician?

3. Highlight Your Technical Skills and Knowledge

Emphasize your technical skills and knowledge of aircraft maintenance and repair. Quantify your accomplishments using specific examples to demonstrate your abilities.

- Describe your experience inspecting, maintaining, and repairing aircraft structures.

- Provide examples of how you have diagnosed and fixed aircraft malfunctions.

- Explain your knowledge of aviation regulations and industry standards.

4. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions about the position, the company, and the industry. This shows that you are engaged and interested in the opportunity.

- What are the company’s goals and priorities for aircraft maintenance?

- What opportunities are there for professional development and advancement?

- How does the company ensure compliance with regulatory requirements?

5. Follow Up After the Interview

After the interview, follow up with a thank-you note to the interviewer. Reiterate your interest in the position and thank them for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Airframe and Powerplant Technician (A and P Technicians) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!