Are you gearing up for a career in Airframe Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Airframe Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

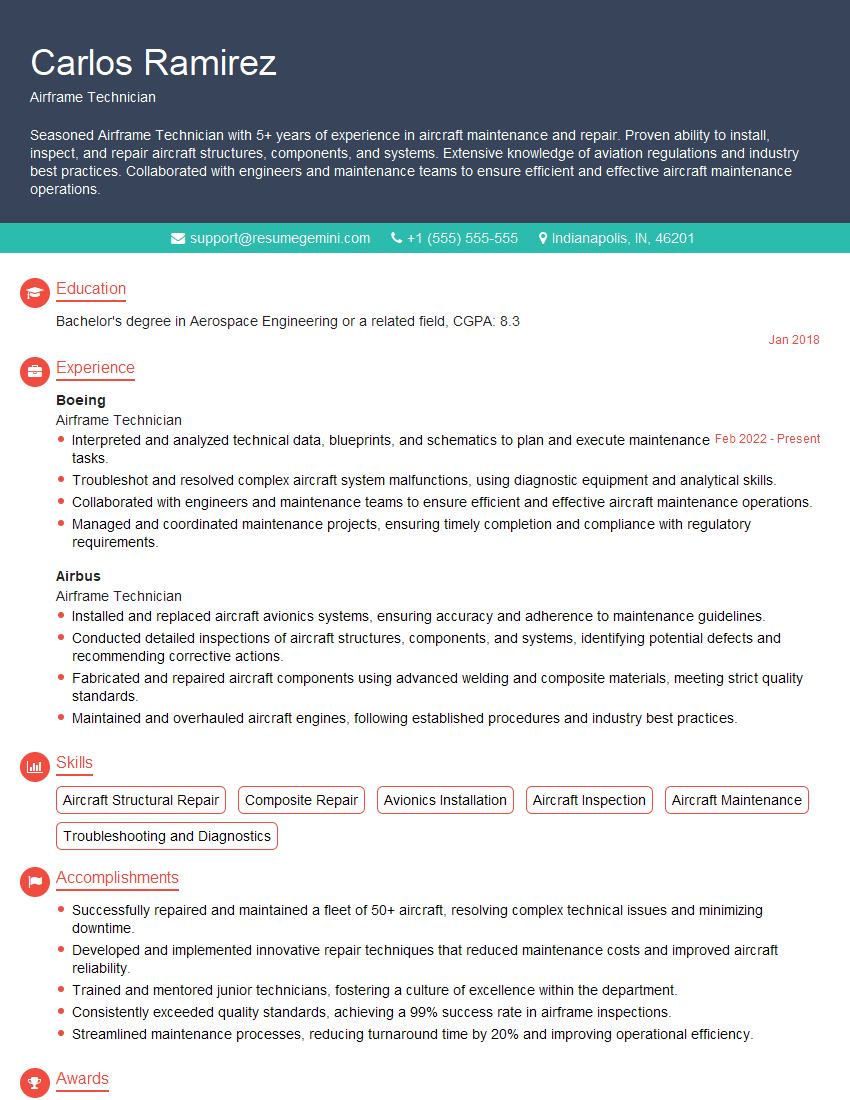

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Airframe Technician

1. Explain the different types of aircraft structures?

Aircraft structures can be classified into three main types:

- Monocoque: A monocoque structure is a shell-like structure that carries loads through its skin. The skin is typically made of a thin, lightweight material such as aluminum or composite materials.

- Semi-monocoque: A semi-monocoque structure is a combination of a monocoque structure and a truss structure. The skin carries some of the loads, but the majority of the loads are carried by the truss.

- Truss: A truss structure is a framework of interconnected members that carry loads through compression and tension. Truss structures are typically used in aircraft wings and landing gear.

2. Describe the different types of aircraft materials and their properties?

Metals

- Aluminum: Aluminum is a lightweight, strong, and corrosion-resistant metal that is commonly used in aircraft structures.

- Steel: Steel is a strong and durable metal that is used in aircraft structures that require high strength.

- Titanium: Titanium is a lightweight, strong, and corrosion-resistant metal that is used in aircraft structures that require high strength and low weight.

Composites

- Carbon fiber reinforced polymer (CFRP): CFRP is a composite material made of carbon fibers embedded in a polymer matrix. CFRP is lightweight, strong, and stiff, and it is used in aircraft structures that require high strength and low weight.

- Glass fiber reinforced polymer (GFRP): GFRP is a composite material made of glass fibers embedded in a polymer matrix. GFRP is lightweight, strong, and corrosion-resistant, and it is used in aircraft structures that require high strength and low weight.

- Kevlar: Kevlar is a synthetic fiber that is used in aircraft structures that require high strength and low weight. Kevlar is also used in bulletproof vests and other protective clothing.

3. Explain the different types of aircraft maintenance?

Aircraft maintenance can be classified into three main types:

- Preventive maintenance: Preventive maintenance is performed on a regular basis to prevent aircraft failures. Preventive maintenance tasks include inspections, lubrication, and minor repairs.

- Corrective maintenance: Corrective maintenance is performed to repair aircraft failures. Corrective maintenance tasks include troubleshooting, repairs, and replacements.

- Overhaul: Overhaul is a major maintenance event that is performed on aircraft at regular intervals. Overhaul tasks include inspections, repairs, and replacements of major components.

4. Describe the different types of aircraft inspections?

Aircraft inspections can be classified into three main types:

- Pre-flight inspection: A pre-flight inspection is a visual inspection of an aircraft that is performed before each flight. The pre-flight inspection checks for any obvious defects or damage that could affect the safety of the flight.

- Post-flight inspection: A post-flight inspection is a visual inspection of an aircraft that is performed after each flight. The post-flight inspection checks for any damage or defects that may have occurred during the flight.

- Periodic inspection: A periodic inspection is a more thorough inspection of an aircraft that is performed at regular intervals. Periodic inspections check for any hidden defects or damage that may not be visible during a pre-flight or post-flight inspection.

5. Describe the process of troubleshooting an aircraft system?

Troubleshooting an aircraft system involves the following steps:

- Identify the problem: The first step is to identify the problem that is affecting the aircraft system. This can be done by observing the symptoms of the problem and by using diagnostic tools.

- Gather information: Once the problem has been identified, gather any relevant information about the aircraft system. This information may include maintenance records, technical manuals, and drawings.

- Analyze the information: Analyze the information gathered in step 2 to determine the root cause of the problem. This may involve using logical reasoning and deduction.

- Develop a solution: Once the root cause of the problem has been identified, develop a solution to fix the problem. The solution may involve repairing or replacing a component, or it may involve adjusting a setting.

- Test the solution: Once the solution has been developed, test the solution to ensure that it fixes the problem. This may involve testing the aircraft system on the ground or in the air.

6. Describe the different types of aircraft repairs?

Aircraft repairs can be classified into two main types:

- Minor repairs: Minor repairs are repairs that can be performed without removing the component from the aircraft. Minor repairs include patching, sealing, and replacing small parts.

- Major repairs: Major repairs are repairs that require the removal of the component from the aircraft. Major repairs include welding, riveting, and replacing large parts.

7. Describe the different types of aircraft modifications?

Aircraft modifications can be classified into two main types:

- Minor modifications: Minor modifications are modifications that do not affect the aircraft’s design or performance. Minor modifications include installing new equipment, adding decals, and painting the aircraft.

- Major modifications: Major modifications are modifications that affect the aircraft’s design or performance. Major modifications include changing the aircraft’s engines, wings, or fuselage.

8. Describe the different types of aircraft tools and equipment?

Aircraft tools and equipment can be classified into the following categories:

- Hand tools: Hand tools are tools that are used to perform manual tasks, such as tightening bolts, cutting wires, and removing panels.

- Power tools: Power tools are tools that are powered by electricity, air, or hydraulics. Power tools are used to perform tasks that require more power than hand tools, such as drilling holes, grinding metal, and sanding surfaces.

- Test equipment: Test equipment is used to test the operation of aircraft systems and components. Test equipment includes multimeters, oscilloscopes, and pressure gauges.

- Specialized equipment: Specialized equipment is used to perform tasks that cannot be performed with hand tools, power tools, or test equipment. Specialized equipment includes jigs, fixtures, and cranes.

9. Describe the different types of aircraft safety regulations?

Aircraft safety regulations are established by government agencies to ensure the safety of aircraft and their occupants. Aircraft safety regulations cover a wide range of topics, including aircraft design, construction, maintenance, and operation.

10. Describe the different types of aircraft careers?

There are many different types of aircraft careers, including:

- Aircraft mechanics: Aircraft mechanics maintain and repair aircraft. They perform a variety of tasks, such as inspecting aircraft, replacing parts, and troubleshooting problems.

- Aircraft engineers: Aircraft engineers design, develop, and test aircraft. They work on a variety of projects, such as designing new aircraft, improving existing aircraft, and developing new technologies.

- Aircraft pilots: Aircraft pilots fly aircraft. They are responsible for operating the aircraft, navigating the aircraft, and ensuring the safety of the passengers.

- Aircraft dispatchers: Aircraft dispatchers plan and coordinate aircraft flights. They work with pilots and other personnel to ensure that flights are operated safely and efficiently.

- Aircraft manufacturers: Aircraft manufacturers build and sell aircraft. They are responsible for designing, manufacturing, and testing aircraft.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Airframe Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Airframe Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Airframe Technicians are responsible for maintaining and repairing the structural components of aircraft, including the fuselage, wings, and tail. They work closely with other aviation professionals to ensure that aircraft are safe and airworthy.

1. Inspect and maintain aircraft structures

Airframe Technicians inspect aircraft structures for damage or wear and tear. They use a variety of tools and techniques to identify and repair any problems. They may also perform preventive maintenance tasks to keep aircraft in good condition.

- Inspect aircraft structures for damage or wear and tear

- Repair damaged or worn aircraft structures

- Perform preventive maintenance tasks to keep aircraft in good condition

2. Fabricate and install aircraft components

Airframe Technicians may also fabricate and install aircraft components. They use specialized tools and techniques to create and install parts that meet the exacting standards of the aviation industry.

- Fabricate aircraft components using specialized tools and techniques

- Install aircraft components according to exacting standards

3. Troubleshoot and repair aircraft systems

Airframe Technicians are also responsible for troubleshooting and repairing aircraft systems. They use their knowledge of aircraft systems to identify and fix problems. They may also work with other aviation professionals to resolve complex issues.

- Troubleshoot and repair aircraft systems

- Work with other aviation professionals to resolve complex issues

4. Follow safety regulations

Airframe Technicians must follow all applicable safety regulations. They work in a safe and efficient manner to ensure the safety of aircraft and passengers.

- Follow all applicable safety regulations

- Work in a safe and efficient manner

Interview Tips

Preparing for an Airframe Technician interview can be daunting, but with the right preparation, you can ace the interview and land the job. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website

- Read the job description carefully

- Check the company’s social media pages

- Read reviews on Glassdoor

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked in an Airframe Technician interview. It is important to practice your answers to these questions so that you can deliver them confidently and clearly.

- Tell me about your experience as an Airframe Technician.

- What are your strengths and weaknesses as an Airframe Technician?

- Why are you interested in working for this company?

- What are your salary expectations?

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and wrinkle-free.

4. Be on time

Punctuality is important in any job interview, but it is especially important in an Airframe Technician interview. This is because Airframe Technicians are often responsible for working on aircraft that are on a tight schedule. If you are late for your interview, it could reflect poorly on your ability to meet deadlines.

5. Be confident

Confidence is key in any job interview. When you are confident, you are more likely to make a good impression on the interviewer. However, it is important to be confident without being arrogant. You should be able to talk about your skills and experience without sounding like you are bragging.

6. Be prepared to talk about your experience

The interviewer will likely ask you about your experience as an Airframe Technician. Be prepared to talk about your skills and experience in detail. You should also be able to provide examples of your work.

7. Be prepared to answer questions about your knowledge of the aviation industry

The interviewer may also ask you questions about your knowledge of the aviation industry. Be prepared to talk about your understanding of aircraft systems and regulations.

8. Be prepared to talk about your career goals

The interviewer may also ask you about your career goals. Be prepared to talk about your plans for the future and how this job fits into your goals.

9. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. Be prepared to ask thoughtful questions that show you are interested in the job.

10. Follow up after the interview

After the interview, be sure to send a thank-you note to the interviewer. This is a simple way to show your appreciation for the opportunity to interview for the job. You can also use the thank-you note to reiterate your interest in the job and to provide any additional information that you may have forgotten to mention during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Airframe Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.