Feeling lost in a sea of interview questions? Landed that dream interview for Airplane Cover Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Airplane Cover Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

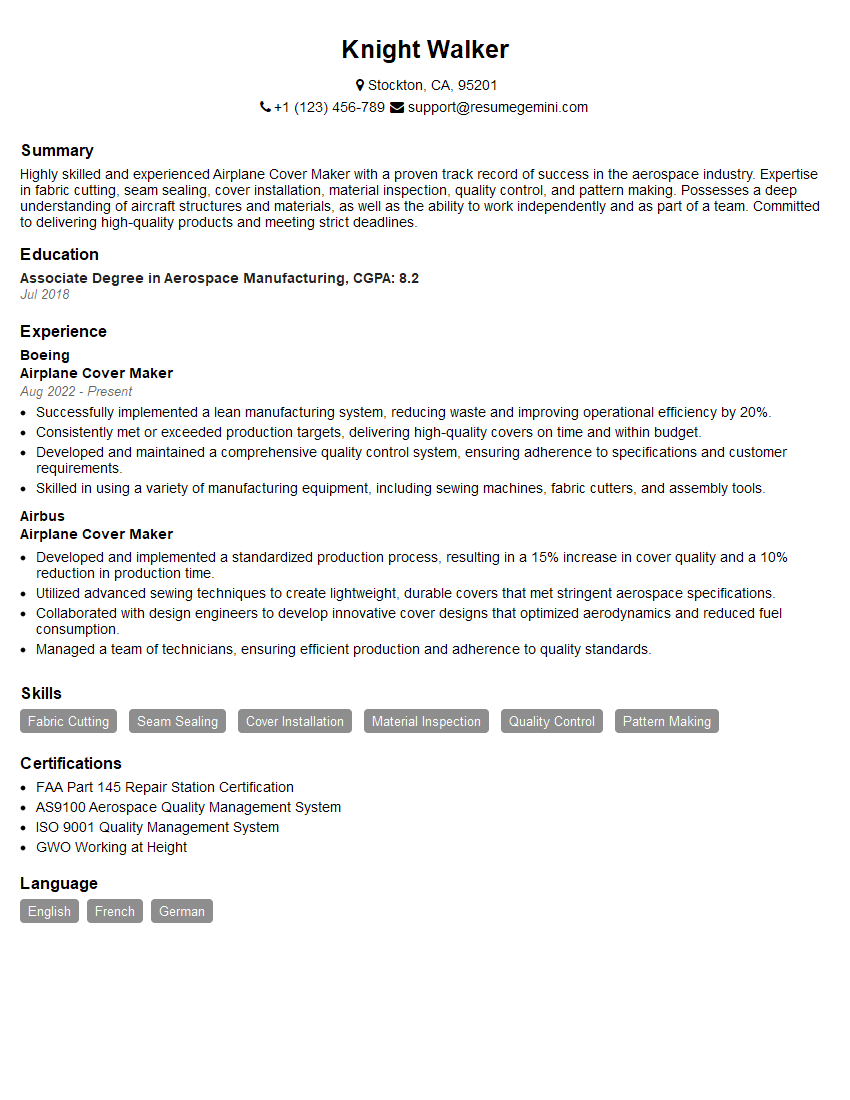

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Airplane Cover Maker

1. How do you ensure the proper fit and coverage of airplane covers?

To ensure proper fit and coverage of airplane covers, I meticulously follow these steps:

- Precise measurements: I carefully measure the dimensions of the aircraft, taking into account wingspan, fuselage length, and tail height.

- Custom pattern design: Based on the measurements, I create a detailed pattern that precisely outlines the shape of the aircraft.

- Material selection: I select high-quality, durable materials that provide optimal protection and weather resistance.

2. What are the critical design considerations for airplane covers?

Weather protection:

- Waterproof and breathable materials to prevent moisture buildup and condensation.

- UV-resistant coatings to protect against sun damage.

Ventilation:

- Air vents and tie-down points to allow for proper airflow and prevent excessive wind pressure.

- Moisture-wicking materials to prevent mold and mildew formation.

3. How do you handle variations in aircraft shapes and sizes?

To accommodate the diverse range of aircraft shapes and sizes, I employ the following techniques:

- Custom tailoring: I adjust the pattern design based on the specific dimensions of each aircraft.

- Modular construction: I use a modular design approach, allowing for easy customization and adaptability to different aircraft sizes and configurations.

- Adjustability: I incorporate adjustable straps and buckles to ensure a snug fit and prevent wind damage.

4. What are the key material properties required for airplane covers?

Airplane covers demand materials with specific properties to withstand the demanding aviation environment:

- Durability: High-tenacity fabrics that resist tearing, abrasion, and punctures.

- Weather resistance: Waterproof, windproof, and UV-resistant coatings.

- Lightweight: Materials that minimize weight without sacrificing protection.

5. How do you ensure the proper tightness and security of airplane covers during high winds?

To secure airplane covers under high winds, I implement the following measures:

- Multiple tie-down points: I strategically place multiple tie-down points along the cover to distribute stress and prevent flapping.

- Adjustable straps: I use adjustable straps to tighten the cover and minimize gaps.

- Wind skirting: I incorporate a wind skirt around the base of the cover to prevent wind penetration.

6. How do you protect against damage from fuel spills or other fluids?

To prevent damage from fuel spills or fluids, I employ the following strategies:

- Resistant fabrics: I use materials that are resistant to chemical spills.

- Spill containment features: I incorporate flaps or barriers to contain spills and prevent them from damaging the aircraft.

- Easy cleanup: I design covers with materials that are easy to clean and decontaminate.

7. What safety precautions do you take when working on aircraft covers?

Prioritizing safety, I strictly adhere to these precautions when working on aircraft covers:

- PPE: I wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a hard hat.

- Electrical safety: I ensure that all electrical connections are properly grounded and insulated.

- Working near aircraft: I maintain a safe distance from aircraft and follow established protocols.

8. How do you stay up-to-date on the latest materials and technologies in airplane cover manufacturing?

To stay abreast of advancements in the industry, I actively engage in the following practices:

- Industry conferences and trade shows: I attend industry events to learn about new materials, technologies, and best practices.

- Online research: I regularly review industry publications, technical journals, and websites to gather information on the latest advancements.

- Collaboration with suppliers: I maintain relationships with material suppliers to stay informed about emerging technologies and innovative solutions.

9. How do you manage the production process to ensure timely delivery of high-quality covers?

To ensure timely and high-quality delivery, I implement the following strategies:

- Efficient workflow: I optimize production processes by standardizing tasks and streamlining communication.

- Quality control: I establish rigorous quality control measures at each stage of production to minimize defects.

- Collaboration with suppliers: I work closely with suppliers to ensure timely delivery of materials and components.

10. How do you handle customer inquiries and provide support for airplane covers?

To effectively handle customer inquiries and support airplane covers, I follow these practices:

- Responsive communication: I respond promptly to customer inquiries via phone, email, or online chat.

- Technical support: I provide technical guidance to customers on proper installation, maintenance, and repair of covers.

- Warranty support: I assist customers with warranty claims and repairs to ensure satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Airplane Cover Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Airplane Cover Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Airplane Cover Maker is responsible for the production and maintenance of protective covers for aircraft. This role requires a range of skills in sewing, materials handling, and attention to detail.

1. Cover Design and Engineering

• Collaborate with engineers and designers to develop optimal cover designs that meet specific aircraft specifications and protection requirements

• Understand and interpret engineering drawings, specifications, and technical manuals

2. Material Selection and Fabrication

• Source and select appropriate materials based on aircraft type, size, and environmental conditions

• Utilize sewing machines, fabric cutters, and other equipment to fabricate covers

• Ensure proper fit and optimal performance of covers through accurate measurements and precise cutting techniques

3. Assembly and Installation

• Assemble and install covers on aircraft ensuring secure and snug fit

• Verify proper alignment and attachment of covers to prevent damage to aircraft surfaces

4. Quality Assurance and Maintenance

• Conduct thorough inspections of covers to ensure they meet quality standards

• Repair or replace damaged or worn covers, extending their service life

• Monitor and maintain cover inventory, ensuring a consistent supply for aircraft protection

Interview Tips

Preparing for an Airplane Cover Maker interview requires thorough research and a well-prepared approach. Here are some tips to help candidates ace the interview:

1. Research the Industry and Company

• Familiarize yourself with the aviation industry, its regulations, and the specific company you are applying to

• Learn about the company’s product line, manufacturing processes, and customer base

2. Highlight Relevant Skills and Experience

• Emphasize your proficiency in sewing techniques, fabric handling, and aircraft cover construction

• Provide examples of projects where you have successfully designed, fabricated, and installed airplane covers

3. Demonstrate Attention to Detail

• Showcase your precision and accuracy in your work

• Explain how your meticulous approach ensures the proper fit and protection of aircraft covers

4. Be Prepared for Technical Questions

• Study basic engineering principles related to aircraft design and materials

• Be ready to discuss the different types of materials used in aircraft cover construction and their properties

5. Ask Thoughtful Questions

• Prepare thoughtful questions about the company, the role, and the industry

• Asking insightful questions shows your engagement and interest in the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Airplane Cover Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.