Are you gearing up for a career in Airplane Mechanic Apprentice? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Airplane Mechanic Apprentice and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

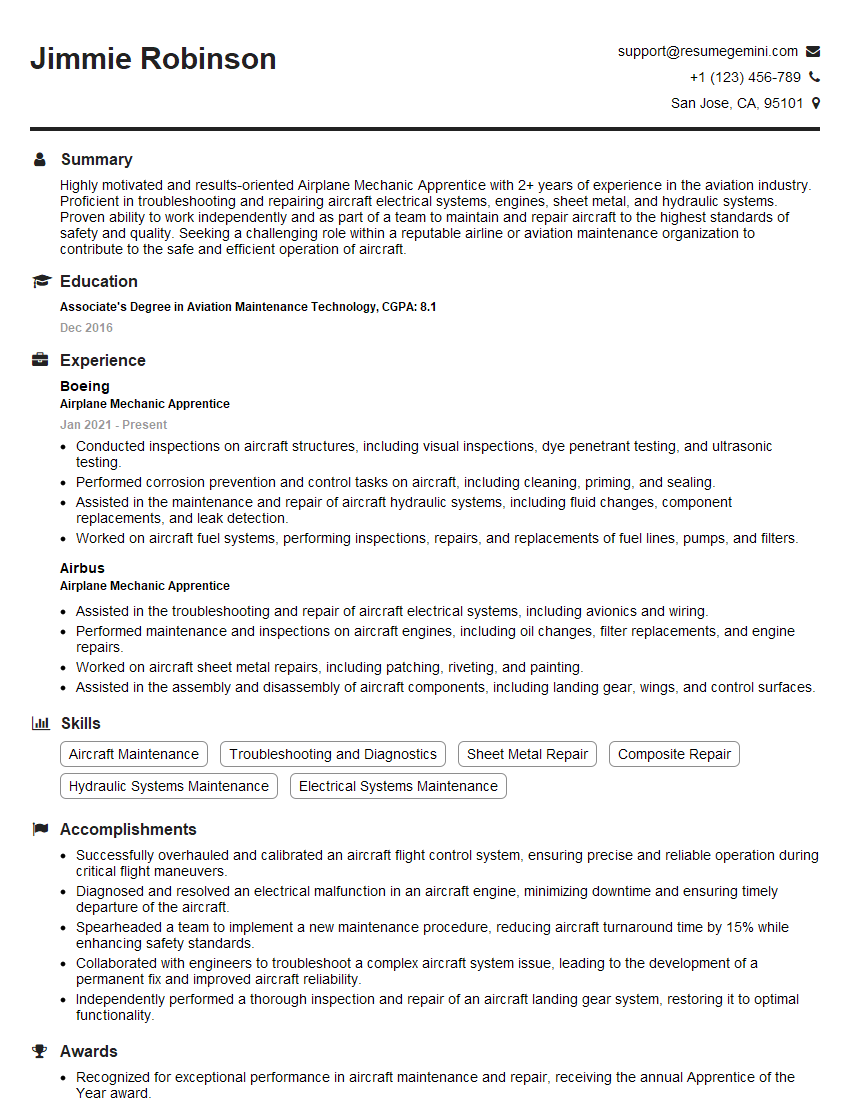

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Airplane Mechanic Apprentice

1. Explain the process of troubleshooting an electrical system on an aircraft?

- First, I would visually inspect the system for any obvious damage or loose connections.

- Next, I would use a multimeter to test the voltage and continuity of the circuits.

- If I found any problems, I would then use a schematic diagram to trace the circuit and identify the faulty component.

- Finally, I would replace the faulty component and test the system to make sure it is working properly.

2. Describe the different types of aircraft hydraulic systems and their functions?

There are two main types of aircraft hydraulic systems: open-center and closed-center.

Open-center systems

- Open-center systems are the most common type of hydraulic system used in aircraft.

- Open-center systems use a pump to continuously circulate hydraulic fluid through the system.

- The pump is constantly running, even when the hydraulic system is not in use.

- Open-center systems are relatively simple and inexpensive to maintain.

Closed-center systems

- Closed-center systems are more efficient than open-center systems.

- Closed-center systems use a pump to pressurize the hydraulic fluid only when it is needed.

- When the hydraulic system is not in use, the pump is turned off.

- Closed-center systems are more complex and expensive to maintain than open-center systems.

3. How would you inspect an aircraft landing gear for damage?

To inspect an aircraft landing gear for damage, I would first look for any obvious signs of damage, such as cracks, dents, or corrosion.

- I would then use a flashlight to inspect the landing gear more closely for any hidden damage.

- I would also use a borescope to inspect the inside of the landing gear for any damage that is not visible from the outside.

- Finally, I would use a torque wrench to check the tightness of all the bolts and nuts on the landing gear.

4. What are the different types of aircraft engines and their advantages and disadvantages?

There are two main types of aircraft engines: piston engines and jet engines.

Piston engines

- Piston engines are the most common type of engine used in small aircraft.

- Piston engines are relatively simple and inexpensive to maintain.

- Piston engines are not as powerful as jet engines, but they are more fuel-efficient.

Jet engines

- Jet engines are more powerful than piston engines, but they are also more complex and expensive to maintain.

- Jet engines are more fuel-efficient than piston engines at high speeds.

5. How would you troubleshoot a problem with an aircraft’s flight control system?

- First, I would visually inspect the flight control system for any obvious damage or loose connections.

- Next, I would use a multimeter to test the voltage and continuity of the circuits.

- If I found any problems, I would then use a schematic diagram to trace the circuit and identify the faulty component.

- Finally, I would replace the faulty component and test the flight control system to make sure it is working properly.

6. What are the different types of aircraft maintenance inspections and their purposes?

There are three main types of aircraft maintenance inspections:

- A inspections are the most basic type of inspection and are performed every 50 flight hours.

- B inspections are more comprehensive than A inspections and are performed every 100 flight hours.

- C inspections are the most comprehensive type of inspection and are performed every 200 flight hours.

7. How would you perform a weight and balance check on an aircraft?

- First, I would gather the aircraft’s weight and balance data.

- Next, I would weigh the aircraft using a calibrated scale.

- I would then use the aircraft’s weight and balance data to calculate the aircraft’s center of gravity.

- Finally, I would compare the aircraft’s center of gravity to the allowable center of gravity range.

8. What are the different types of aircraft fuel systems and their components?

There are two main types of aircraft fuel systems: gravity-feed systems and pressure-feed systems.

Gravity-feed systems

- Gravity-feed systems are the simplest type of fuel system and are used in small aircraft.

- Gravity-feed systems use gravity to move fuel from the fuel tank to the engine.

- Gravity-feed systems are relatively simple and inexpensive to maintain.

Pressure-feed systems

- Pressure-feed systems are more complex than gravity-feed systems, but they are also more efficient.

- Pressure-feed systems use a pump to move fuel from the fuel tank to the engine.

- Pressure-feed systems are more expensive to maintain than gravity-feed systems.

9. How would you troubleshoot a problem with an aircraft’s electrical system?

- First, I would visually inspect the electrical system for any obvious damage or loose connections.

- Next, I would use a multimeter to test the voltage and continuity of the circuits.

- If I found any problems, I would then use a schematic diagram to trace the circuit and identify the faulty component.

- Finally, I would replace the faulty component and test the electrical system to make sure it is working properly.

10. What are the different types of aircraft instruments and their functions?

There are many different types of aircraft instruments, each with its own specific function.

- Airspeed indicator measures the aircraft’s speed relative to the air.

- Altimeter measures the aircraft’s altitude above sea level.

- Attitude indicator measures the aircraft’s pitch and roll.

- Compass measures the aircraft’s heading.

- Engine instruments measure the engine’s performance, such as RPM and temperature.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Airplane Mechanic Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Airplane Mechanic Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Airplane Mechanic Apprentice, you will assist experienced mechanics in performing various maintenance and repair tasks on aircraft. Your key responsibilities will include:

1. Assisting with Aircraft Inspections and Maintenance

Conducting thorough visual inspections of aircraft to identify any potential issues or defects.

- Reporting identified issues and defects to senior mechanics for further assessment and repair.

- Assisting with routine maintenance tasks, such as changing oil, filters, and fluids.

2. Assisting with Aircraft Repairs

Assisting senior mechanics in repairing damaged or malfunctioning aircraft components, systems, and structures.

- Following technical manuals and diagrams to identify and replace faulty parts.

- Testing and inspecting repaired components to ensure proper functionality before reinstallation.

3. Maintaining Tools and Equipment

Maintaining a clean and organized work area.

- Calibrating and testing tools and equipment to ensure accuracy and safety.

- Storing tools and equipment properly to prevent damage or loss.

4. Adhering to Safety Regulations

Complying with all applicable safety regulations and procedures.

- Wearing appropriate safety gear, such as gloves, safety glasses, and coveralls.

- Following proper handling and storage protocols for hazardous materials.

Interview Tips

To prepare for your interview and increase your chances of success, consider the following tips:

1. Research the Company and Position

Demonstrate your interest in the company and the specific role. Research their history, values, and current projects.

- Visit the company website and social media pages.

- Read industry news and articles about the company and the aviation sector.

2. Practice Your Answers to Common Interview Questions

Prepare your responses to common interview questions related to your skills, experience, and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Highlight your relevant skills and experience, and how they match the requirements of the role.

3. Emphasize Your Passion for Aviation

Convey your enthusiasm and commitment to the aviation industry.

- Share any experiences or projects that demonstrate your interest in airplanes and mechanics.

- Explain how you stay up-to-date with advancements in aircraft technology.

4. Ask Insightful Questions

Asking thoughtful questions shows your engagement and interest in the role and company.

- Inquire about the company’s growth plans and future projects.

- Ask about opportunities for professional development and training.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Airplane Mechanic Apprentice, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Airplane Mechanic Apprentice positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.