Feeling lost in a sea of interview questions? Landed that dream interview for Alemite Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Alemite Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

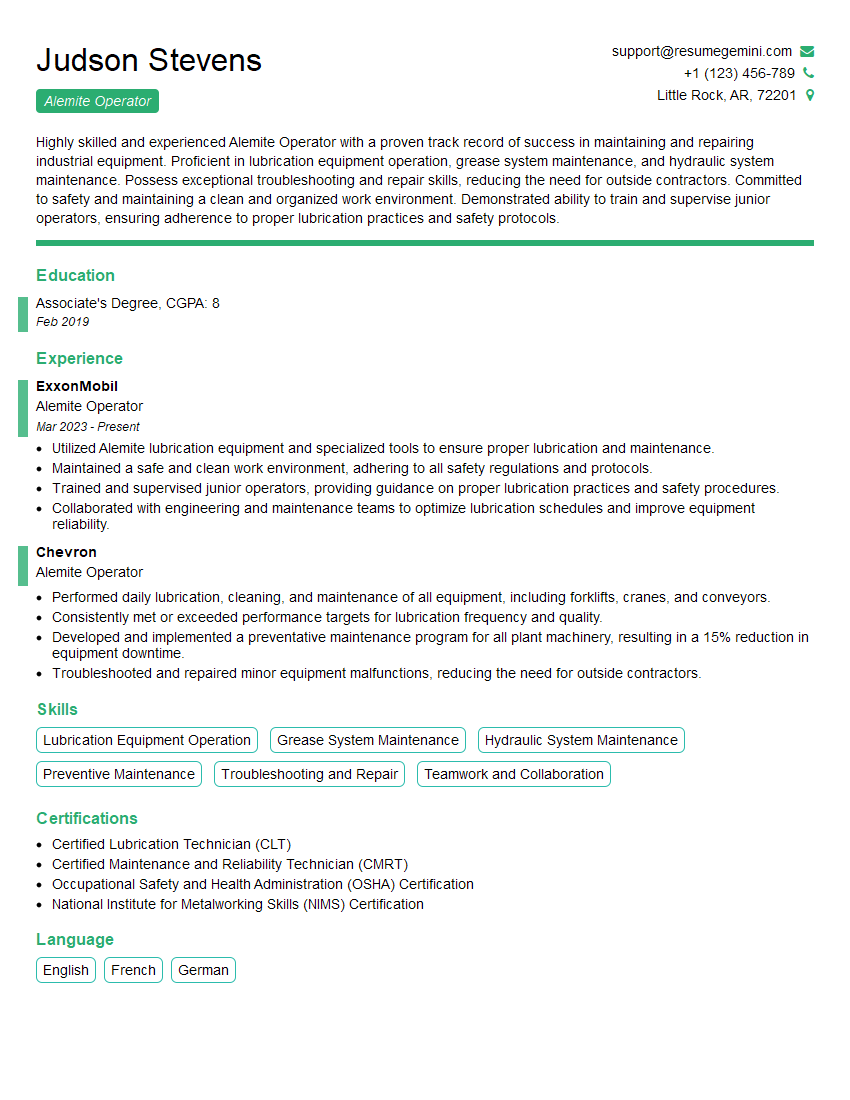

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Alemite Operator

1. Describe the key responsibilities of an Alemite Operator?

- Prepare and lubricate equipment using Alemite tools and equipment.

- Inspect equipment for leaks and wear, and make necessary repairs.

- Maintain a clean and organized work area.

- Follow all safety protocols and procedures.

2. What are the different types of lubricants used in Alemite systems?

Petroleum-based lubricants

- Mineral oils

- Synthetic oils

Synthetic lubricants

- Polyalphaolefins (PAOs)

- Perfluoropolyethers (PFPEs)

3. How do you determine the correct type of lubricant for a specific application?

- Consider the operating temperature of the equipment.

- Consider the speed of the equipment.

- Consider the load on the equipment.

- Consult with the equipment manufacturer’s recommendations.

4. What are the most common Alemite fittings?

- Zerk fittings

- Button head fittings

- Hex head fittings

- Inverted flare fittings

5. How do you troubleshoot a leaking Alemite fitting?

- Check the fitting for damage.

- Check the O-ring for wear.

- Tighten the fitting.

- Replace the fitting if necessary.

6. What are the safety precautions that must be taken when working with Alemite systems?

- Wear eye protection.

- Wear gloves.

- Use proper lifting techniques.

- Follow all lockout/tagout procedures.

7. How do you maintain an Alemite lubrication system?

- Inspect the system regularly for leaks.

- Change the lubricant according to the manufacturer’s recommendations.

- Clean the system periodically.

- Calibrate the system if necessary.

8. What is the difference between an Alemite grease gun and an oil gun?

- Grease guns are used to apply grease to Alemite fittings.

- Oil guns are used to apply oil to oil fittings.

9. What are the different types of Alemite grease guns?

- Manual grease guns

- Air-operated grease guns

- Battery-operated grease guns

10. How do you choose the right Alemite grease gun for a specific application?

- Consider the pressure required for the application.

- Consider the volume of grease required for the application.

- Consider the portability of the grease gun.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Alemite Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Alemite Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of an Alemite Operator

An Alemite Operator is responsible for maintaining and repairing lubrication systems in industrial and commercial settings. Key job responsibilities include:1. Lubrication Equipment Maintenance and Repair

- Maintaining, repairing, and calibrating Alemite lubrication equipment, such as grease guns, pumps, and other related equipment

- Inspecting, cleaning, and servicing equipment to ensure proper operation

- Troubleshooting and resolving equipment malfunctions

2. Lubrication System Management

- Developing and implementing lubrication schedules based on equipment specifications

- Monitoring and adjusting lubrication systems to optimize performance and extend equipment life

- Assessing lubrication requirements and recommending appropriate lubricants for various applications

3. Safety and Environmental Compliance

- Adhering to health, safety, and environmental regulations while working with lubricants and solvents

- Maintaining proper storage and handling practices for lubrication products

- Promoting a safe work environment and following proper disposal procedures for used lubricants

4. Documentation and Reporting

- Maintaining records of lubrication activities, including equipment inspections, repairs, and lubricant usage

- Reporting any equipment or system issues to supervisors and making recommendations for corrective actions

- Providing technical support and documentation to other plant personnel

Interview Preparation Tips for Alemite Operators

To ace an interview for an Alemite Operator position, follow these tips:1. Research the Company and Position

- Familiarize yourself with the company’s history, values, and industry presence

- Review the job description thoroughly to understand the specific responsibilities and qualifications required

- Tailor your resume and cover letter to highlight your relevant skills and experience

2. Practice Common Interview Questions

- Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?”

- Consider behavioral interview questions that focus on your past experiences and how you handled specific situations

- Practice answering questions related to lubrication equipment, maintenance procedures, and safety protocols

3. Demonstrate Your Technical Skills

- Highlight your knowledge of lubrication principles, equipment operation, and troubleshooting techniques

- Provide examples of successful maintenance and repair projects you have completed

- Show your understanding of lubrication system management, including scheduling and monitoring

4. Emphasize Your Safety and Environmental Awareness

- Explain your commitment to safety and compliance with industry regulations

- Describe your experience in handling hazardous materials and working safely in industrial environments

- Discuss your understanding of proper lubrication product storage, use, and disposal practices

5. Show Your Dedication and Passion

- Express your enthusiasm for the role and how it aligns with your career goals

- Convey your willingness to learn and grow in the field

- Ask informed questions about the company, position, and lubrication industry to demonstrate your interest and engagement

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Alemite Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.