Feeling lost in a sea of interview questions? Landed that dream interview for Alining Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Alining Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

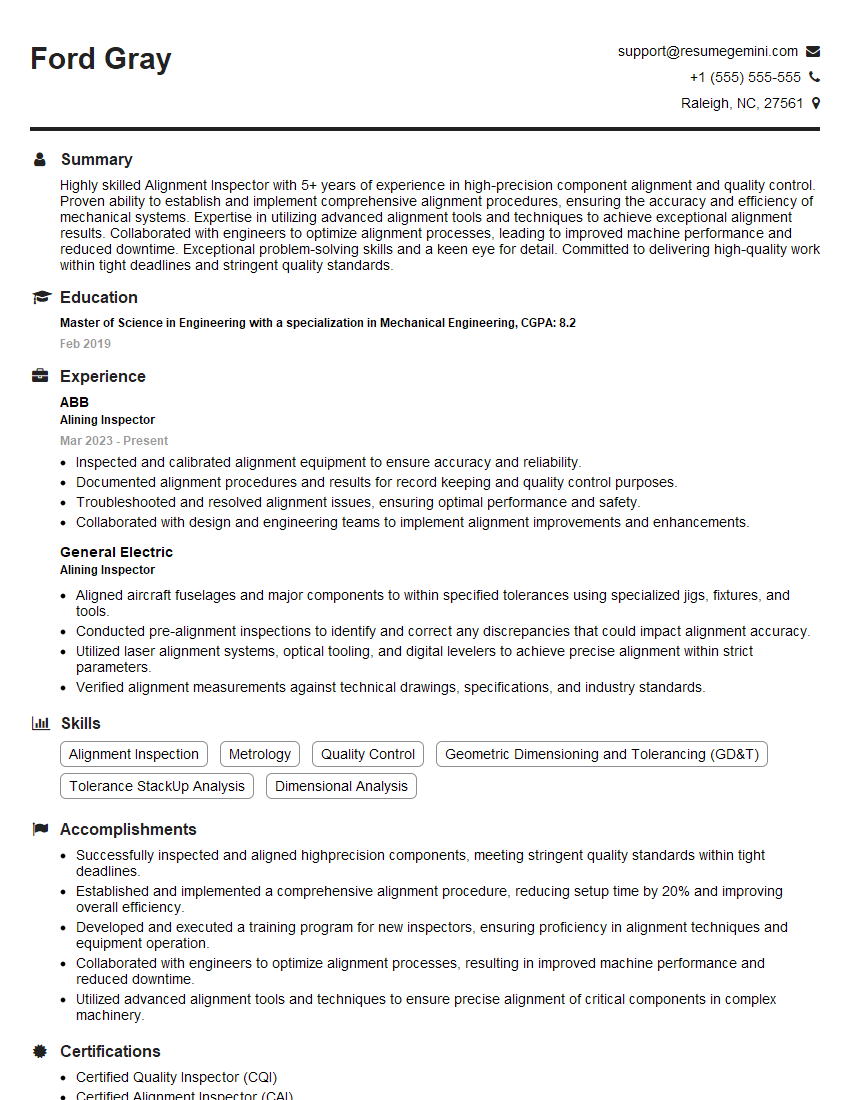

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Alining Inspector

1. What are the key responsibilities of an Aligning Inspector?

- Inspect and align components and assemblies to ensure they meet specified tolerances.

- Use precision measuring tools to measure and record alignment data.

- Identify and correct alignment errors using hand tools or specialized equipment.

- Maintain and calibrate inspection equipment.

- Prepare and maintain inspection records.

2. What are the different types of alignment methods used in your field?

Alignment by Visual Inspection

- Using a visual alignment tool to check alignment.

- Observing the alignment by eyesight or with the help of precision instruments.

Alignment by Laser

- Using a laser beam to project a reference line or plane.

- Adjusting the components until they are aligned with the laser beam.

Alignment by Dial Indicator

- Using a dial indicator to measure the relative movement of two surfaces.

- Adjusting the components until the dial indicator reads zero.

Alignment by CMM (Coordinate Measuring Machine)

- Using a CMM to measure the geometry and alignment of the components.

- Comparing the measured data to the CAD model to identify any deviations.

3. What are the common measuring tools used by Aligning Inspectors?

- Dial indicators

- Levels

- Squares

- Micrometers

- Calipers

- Coordinate Measuring Machines (CMMs)

- Laser alignment systems

4. What are the different types of tolerances that an Aligning Inspector may encounter?

- Linear tolerances

- Angular tolerances

- Radial tolerances

- Geometric tolerances

- Surface finish tolerances

5. What are the steps involved in aligning a component or assembly?

- Identify the reference surfaces or points that will be used for alignment.

- Measure the current alignment of the component or assembly.

- Determine the necessary adjustments to bring the component or assembly into alignment.

- Make the necessary adjustments using hand tools or specialized equipment.

- Verify the alignment of the component or assembly.

6. What are the potential sources of alignment errors?

- Manufacturing defects

- Improper assembly

- Environmental factors (e.g., temperature, vibration)

- Wear and tear

- Human error

7. What are the consequences of misalignment?

- Reduced performance

- Increased wear and tear

- Failure of the component or assembly

- Safety hazards

8. What are the best practices for preventing misalignment?

- Use precise measuring tools.

- Follow proper assembly procedures.

- Regularly inspect and maintain equipment.

- Train personnel on proper alignment techniques.

- Use self-aligning components when possible.

9. What is your experience with interpreting and applying engineering drawings and specifications for alignment purposes?

- I am proficient in reading and interpreting engineering drawings and specifications.

- I have experience in using engineering drawings to determine the required alignment tolerances and specifications.

- I am able to apply engineering specifications to ensure that the alignment of components and assemblies meets the required standards.

10. Describe a time when you identified and corrected a misalignment issue.

- I was working on a project where a component was not aligning properly.

- I used precision measuring tools to identify the misalignment and determine the necessary corrections.

- I made the necessary adjustments to bring the component into alignment.

- I verified the alignment of the component and ensured that it met the required specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Alining Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Alining Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Aligning Inspector plays a crucial role in ensuring the accuracy and precision of alignment processes in various industries. Their responsibilities include:

1. Equipment Alignment

Inspect and align machinery and equipment to specified tolerances using precision measuring instruments.

- Conduct laser alignments, shaft alignments, and geometric alignments.

- Verify the proper installation and operation of equipment.

2. Inspection and Quality Control

Check the alignment of components, assemblies, and structures to ensure they meet engineering specifications.

- Identify and correct alignment errors using appropriate techniques.

- Document inspection findings and maintain quality records.

3. Troubleshooting and Problem Solving

Diagnose and resolve alignment-related issues that affect equipment performance and efficiency.

- Identify the root cause of alignment problems using analytical skills.

- Recommend and implement solutions to improve alignment accuracy.

4. Communication and Reporting

Communicate technical information related to alignment inspections and findings to engineers, technicians, and other stakeholders.

- Prepare and submit inspection reports, documentation, and recommendations.

- Provide consultation and support on alignment-related matters.

Interview Tips

To ace an interview for an Aligning Inspector position, candidates should:

1. Technical Expertise

Demonstrate a deep understanding of alignment principles, inspection techniques, and measuring instruments.

- Highlight your experience with laser alignment, shaft alignment, and geometric alignment.

- Explain how you ensure accuracy and precision in your alignment processes.

2. Analytical Skills

Show your ability to diagnose and troubleshoot alignment problems effectively.

- Provide examples of how you have solved complex alignment issues in previous roles.

- Describe your approach to problem-solving and critical thinking.

3. Communication and Interpersonal Skills

Emphasize your ability to communicate technical information clearly and effectively.

- Explain how you collaborate with engineers, technicians, and other stakeholders.

- Highlight your written and verbal communication skills for reporting and documentation.

4. Industry Knowledge

Demonstrate familiarity with the specific industry or application for which you are interviewing.

- Research the company, its products, and the alignment requirements specific to their industry.

- Tailor your answers to the job requirements and show how your experience aligns with the company’s needs.

5. Practice and Preparation

Prepare for common interview questions by practicing your answers and researching relevant industry topics.

- Review alignment techniques, quality control standards, and industry trends.

- Be ready to discuss your experience and qualifications in detail.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Alining Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.