Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Alloy Weigher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

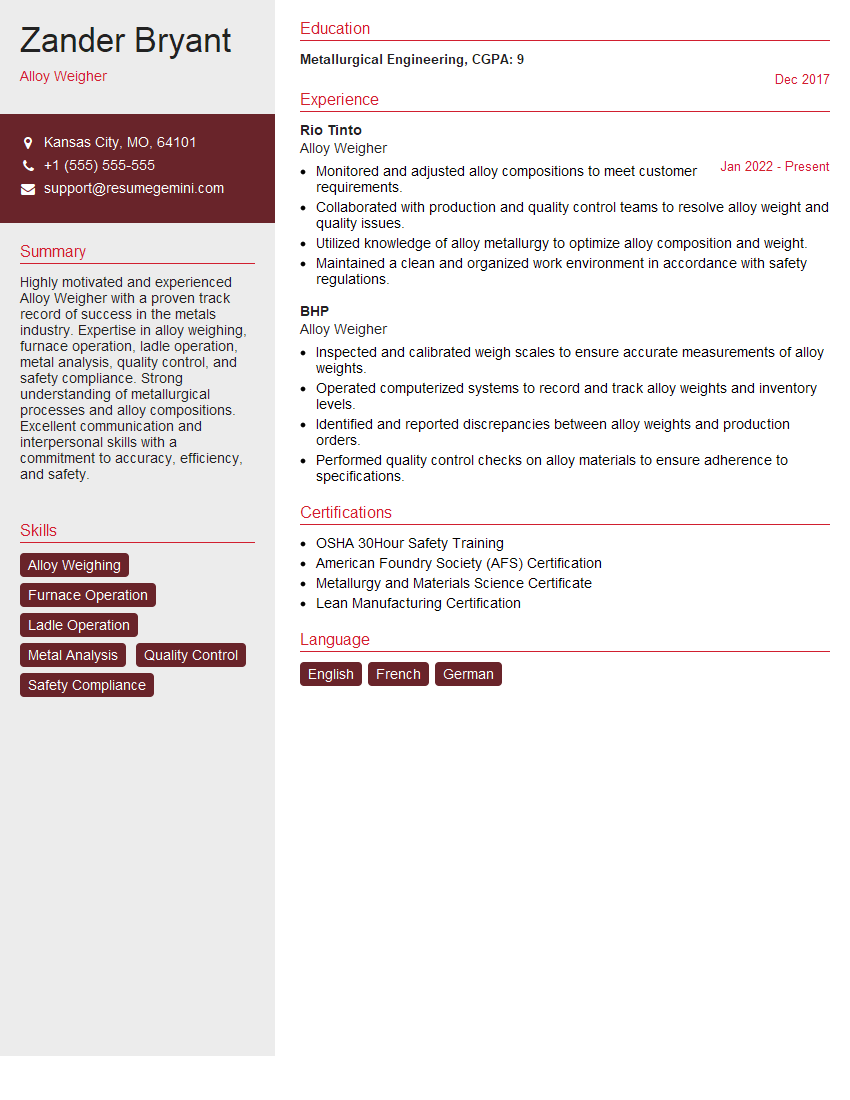

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Alloy Weigher

1. What are the different types of alloy weighers and their uses?

- Benchtop Alloy Weighers: These are compact and portable weighing scales that are used for weighing small amounts of alloys in laboratories and workshops.

- Floor Alloy Weighers: These are large and sturdy weighing scales that are used for weighing heavy alloys in industrial settings.

- Crane Alloy Weighers: These are specialized weighing scales that are suspended from cranes and used for weighing heavy alloys that are difficult to move.

2. What are the key factors to consider when selecting an alloy weigher?

Accuracy

- The accuracy of an alloy weigher refers to its ability to measure the weight of an object within a specified range.

- Accuracy is expressed in terms of the scale’s resolution, which is the smallest increment that the scale can measure.

Capacity

- The capacity of an alloy weigher refers to the maximum weight that it can handle.

- It is important to select an alloy weigher with a capacity that is appropriate for the intended use.

3. What are the different methods used for calibrating alloy weighers?

- Internal Calibration: This method uses a built-in calibration mechanism within the alloy weigher to adjust the scale’s accuracy.

- External Calibration: This method involves using external calibration weights to calibrate the alloy weigher.

4. What are the maintenance procedures for alloy weighers?

- Regular Cleaning: Alloy weighers should be regularly cleaned to remove any dirt or debris that may affect their accuracy.

- Calibration: Alloy weighers should be calibrated regularly to ensure their accuracy.

- Lubrication: Moving parts of alloy weighers should be lubricated periodically to ensure smooth operation.

5. What are the safety precautions to observe when using alloy weighers?

- Proper Handling: Alloy weighers should be handled carefully to avoid damage.

- Overloading: Alloy weighers should not be overloaded as this can damage the scale.

- Electrical Safety: Electrical connections of alloy weighers should be properly maintained to avoid electrical hazards.

6. What are the advantages of using digital alloy weighers over analog alloy weighers?

- Higher Accuracy: Digital alloy weighers provide higher accuracy in measurements compared to analog alloy weighers.

- Ease of Use: Digital alloy weighers are easier to use as they display the weight digitally, eliminating the need for manual calculations.

- Data Storage: Digital alloy weighers often have data storage capabilities, allowing for easy record keeping.

7. What are the different types of sensors used in alloy weighers?

- Strain Gauge Sensors: Strain gauge sensors measure the strain induced in a material when a load is applied.

- Load Cell Sensors: Load cell sensors convert the force applied to them into an electrical signal.

- Piezoelectric Sensors: Piezoelectric sensors generate an electrical charge when subjected to mechanical stress or strain.

8. What are the factors that affect the accuracy of alloy weighers?

- Environmental Conditions: Temperature, humidity, and vibrations can affect the accuracy of alloy weighers.

- Calibration: Regular calibration is crucial for maintaining the accuracy of alloy weighers.

- Operator error: Improper handling or incorrect calibration can lead to inaccurate measurements.

9. What are the applications of alloy weighers in various industries?

- Jewelry Manufacturing: Alloy weighers are used to weigh precious metals and gemstones.

- Automotive Industry: Alloy weighers are used to weigh components in vehicles.

- Aerospace Industry: Alloy weighers are used to weigh aircraft components and parts.

- Construction Industry: Alloy weighers are used to weigh concrete, steel, and other building materials.

10. What are the latest advancements in alloy weigher technology?

- Wireless Connectivity: Alloy weighers with wireless connectivity allow for remote monitoring and data transfer.

- Improved Sensors: Advancements in sensor technology have led to increased accuracy and stability in alloy weighers.

- Data Analytics: Alloy weighers integrated with data analytics capabilities provide insights into weighing data.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Alloy Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Alloy Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Alloy Weigher is responsible for weighing and measuring alloys, metals, and other materials in various manufacturing and industrial settings. The primary objective is to ensure accurate and precise measurement of materials for production, inventory management, and quality control purposes.

1. Weighing and Measuring Alloys

Weigh and measure alloys, metals, and other materials using precision scales, balances, and other weighing equipment.

- Operate and maintain weighing equipment, ensuring accuracy and calibration.

- Follow standardized weighing procedures to ensure consistent and reliable results.

2. Recording and Documenting Measurements

Record and document weighing measurements accurately and clearly in appropriate logs, reports, or databases.

- Maintain detailed records of all weighing activities, including the date, time, weights, and any relevant observations.

- Document any discrepancies or variations in weighing results to ensure traceability and accountability.

3. Quality Control and Inspection

Assist in quality control by verifying the accuracy of weighing measurements and identifying any potential errors or discrepancies.

- Monitor weighing processes to ensure compliance with quality standards and specifications.

- Participate in product inspections and quality audits to assess the accuracy of weighing measurements.

4. Material Handling and Inventory Management

Assist in the handling and movement of alloys, metals, and other materials within the facility.

- Load and unload materials from weighing equipment and transport them to designated storage areas.

- Maintain inventory records and assist with inventory management activities as needed.

Interview Tips

Preparing for an Alloy Weigher interview can increase your chances of success. Here are some tips to consider:

1. Research the Company and Position

Take time to research the company and the specific role you are applying for. This will help you understand the company’s industry, culture, and the scope of the position’s responsibilities.

- Visit the company’s website and read about their mission, values, and products or services.

- Review the job description thoroughly to identify the key requirements and qualifications for the role.

2. Highlight Your Skills and Experience

In your interview, emphasize your relevant skills and experience that align with the job requirements. Provide specific examples to demonstrate your expertise in weighing and measuring alloys.

- Discuss your experience operating precision scales, balances, and other weighing equipment.

- Mention your ability to accurately record and document weighing measurements in detail.

3. Showcase Your Attention to Detail and Accuracy

Alloy Weighers must be highly attentive to detail and ensure the accuracy of their measurements. Highlight your strengths in these areas during the interview.

- Explain how you maintain and calibrate weighing equipment to ensure precision.

- Describe your process for verifying the accuracy of weighing results and identifying potential errors.

4. Prepare for Common Interview Questions

Prepare for common interview questions related to the role of an Alloy Weigher. Anticipate questions about your experience, skills, and specific responsibilities as a Weigher.

- Practice answering questions about your experience in weighing and measuring alloys.

- Be ready to discuss your understanding of quality control standards and your role in ensuring measurement accuracy.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Alloy Weigher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.