Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Almond Blancher Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

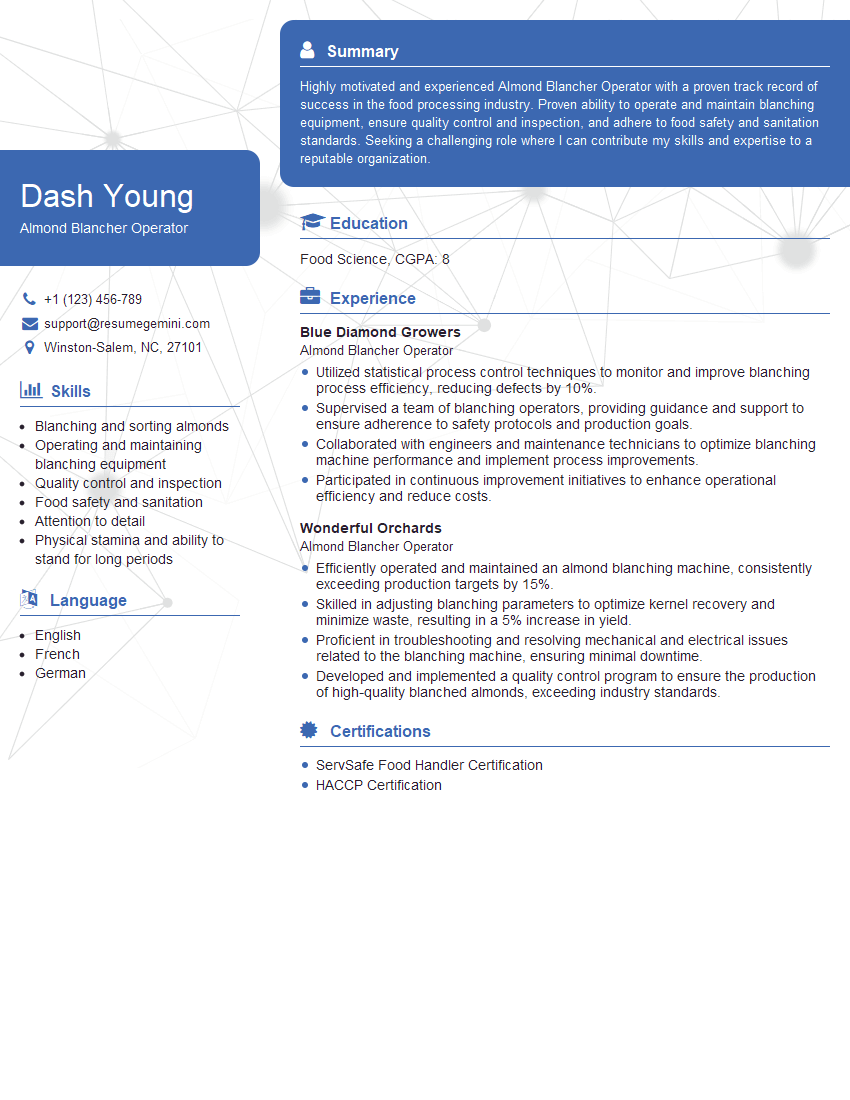

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Almond Blancher Operator

1. What are the key responsibilities of an Almond Blancher Operator?

- Operate and monitor almond blanching machines to remove the skin from almonds.

- Ensure that machines are operating properly and make adjustments as necessary.

2. Explain the process of almond blanching?

Blanching Process

- Soaking almonds in water to loosen the skin.

- Passing almonds through a blanching machine that rubs off the skin.

Quality Control

- Inspecting blanched almonds for any remaining skin or defects.

- Ensuring that almonds meet quality standards.

3. What are the different types of almond blanching machines available?

- Batch blanchers: Process small batches of almonds at a time.

- Continuous blanchers: Process large volumes of almonds continuously.

- Dry blanchers: Use friction to remove the skin without water.

- Wet blanchers: Use water to loosen the skin before removing it.

4. Describe the safety procedures that must be followed when operating an almond blanching machine?

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hairnet.

- Keeping the work area clean and free of hazards.

- Following lockout/tagout procedures when performing maintenance or repairs.

5. What are the common problems that can occur during almond blanching and how do you troubleshoot them?

-

Problem: Almonds not blanching properly

Troubleshooting:

- Check if the blanching machine is set to the correct temperature and speed.

- Inspect the almonds for any defects or damage. Problem: Almonds breaking during blanching Troubleshooting:

- Reduce the speed of the blanching machine.

- Check if the almonds are too dry or too wet.

6. How do you maintain and calibrate an almond blanching machine?

Maintenance:- Cleaning the machine regularly to remove any almond residue or debris.

- Inspecting the machine for any signs of wear or damage.

- Lubricating moving parts as per the manufacturer’s instructions.

- Using a calibration tool to ensure that the machine is blanching almonds to the desired specification.

- Adjusting the machine settings as necessary.

7. How do you ensure the quality of blanched almonds?

- Visually inspecting blanched almonds for any defects or damage.

- Using a quality control chart to track the blanching process and identify any trends or problems.

- Taking corrective actions as necessary to maintain the desired quality standards.

8. What are the different applications of blanched almonds?

- Direct consumption as a snack.

- Used as an ingredient in various food products, such as baked goods, confectionery, and ice cream.

- Almond milk and almond butter.

9. How do you stay updated on the latest advancements in almond blanching technology?

- Attending industry conferences and workshops.

- Reading trade publications and technical journals.

- Consulting with equipment manufacturers and suppliers.

10. How do you measure the efficiency of an almond blanching operation?

- Calculating the throughput rate of the blanching machine.

- Measuring the yield of blanched almonds as a percentage of the input.

- Monitoring the quality of blanched almonds and identifying any defects or damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Almond Blancher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Almond Blancher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Almond Blancher Operators are responsible for efficiently operating almond blanching machines to remove the skins from almonds. Their primary duties include:

1. Almond Preparation and Handling

Prepares almonds for blanching by inspecting, sorting and sizing the raw almonds.

- Inspects and removes any damaged or discolored almonds to ensure only high-quality almonds enter the blanching process.

- Sorts and classifies almonds based on their size to ensure optimal blanching conditions for different sizes.

2. Almond Blanching Operation

Operates and monitors almond blanching machines to effectively remove almond skins.

- Adjusts blanching parameters such as temperature, water flow, and blanching time to optimize the skin removal process.

- Monitors the blanching process to ensure almonds are adequately blanched while avoiding over-blanching.

3. Quality Control and Inspection

Conducts quality control checks on blanched almonds to ensure adherence to quality standards.

- Inspects blanched almonds visually and manually to identify any remaining skins, discoloration, or other defects.

- Separates defective almonds from blanched almonds to maintain product quality.

4. Machine Maintenance and Cleaning

Performs routine maintenance and cleaning of almond blanching machines to ensure optimal performance.

- Cleans and sanitizes blanching machines and equipment regularly to maintain hygiene and prevent contamination.

- Conducts minor repairs and maintenance tasks on blanching machines to keep them in good working condition.

Interview Tips

To effectively prepare for an Almond Blancher Operator interview and increase your chances of success, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and its role in the almond industry. Understanding the company’s culture and industry trends will enhance your credibility during the interview.

- Visit the company website and social media pages to gather information about their operations, products, and recent developments.

- Research the almond industry, including market trends, major players, and current issues affecting the industry.

2. Highlight Relevant Experience and Skills

In your resume and interview, emphasize your experience in operating almond blanching machines or similar equipment.

- Quantify your accomplishments with specific metrics whenever possible. For instance, “Reduced almond blanching time by 10% while maintaining quality standards.”

- If you have experience with different types of blanching machines, highlight your proficiency and adaptability.

3. Demonstrate Quality Consciousness

Almond blanching operators play a crucial role in ensuring the quality of blanched almonds. In the interview, demonstrate your understanding of quality control processes and your commitment to maintaining high standards.

- Provide examples of how you have implemented quality control measures in previous roles, such as visual inspection techniques or defect sorting procedures.

- Explain how you handle situations where you identify defective almonds during the blanching process.

4. Show Eagerness to Learn and Develop

Almond blanching technology and industry practices are constantly evolving. As an Almond Blancher Operator, you should express a willingness to learn new techniques and adapt to changes.

- Share examples of how you have proactively sought out training or professional development opportunities in the past.

- Discuss your interest in staying updated on the latest industry trends and best practices.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Almond Blancher Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Almond Blancher Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.