Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Alum Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

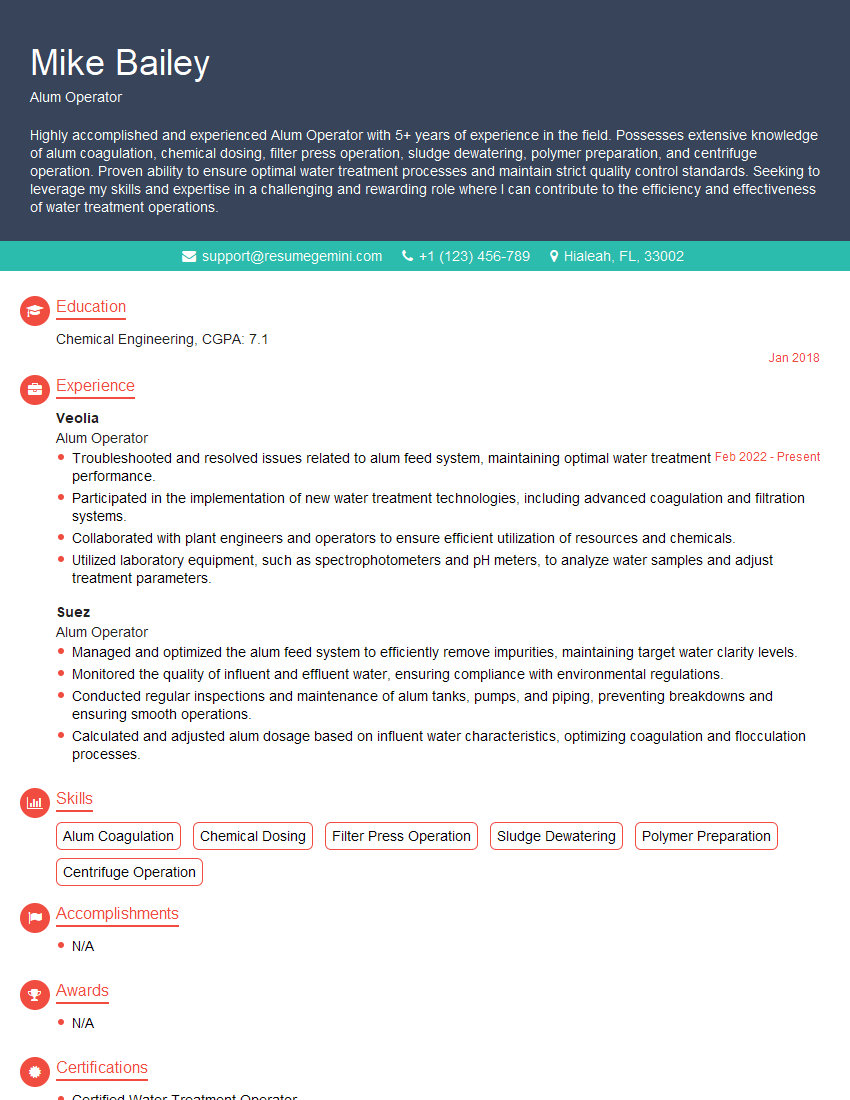

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Alum Operator

1. Describe the key responsibilities of an Alum Operator?

An Alum Operator is responsible for the operation and maintenance of the alum treatment process in a water treatment plant. Key responsibilities include:

- Monitoring and maintaining the alum feed system

- Controlling the alum dosage to ensure effective coagulation and flocculation

- Monitoring and maintaining the pH of the water

- Monitoring and maintaining the settling tanks

- Monitoring and maintaining the sludge removal system

- Maintaining records and logs

- Troubleshooting and resolving operational issues

2. What are the different types of alum used in water treatment?

- Aluminum sulfate [Al2(SO4)3·18H2O]

- Sodium aluminate [Na2Al2O4]

- Polyaluminum chloride [Aln(OH)mCl3n-m]

3. What are the factors that affect the efficiency of alum coagulation?

- pH

- Temperature

- Turbidity

- Alkalinity

- Type of alum used

- Mixing intensity

4. How do you determine the optimum alum dosage?

The optimum alum dosage can be determined through jar testing. Involves adding different doses of alum to a series of water samples and observing the resulting floc formation.

5. What are the common problems encountered in alum coagulation?

- Overdosing, which can lead to high residual aluminum levels

- Underdosing, which can lead to poor coagulation and ineffective removal of impurities

- pH control issues, which can affect the efficiency of coagulation

- Sludge settling issues, which can lead to carryover of solids into the treated water

6. What are the safety precautions that should be taken when working with alum?

- Wear gloves, eye protection, and a dust mask

- Avoid contact with skin and eyes

- Work in a well-ventilated area

- Follow proper handling and storage procedures

7. How do you maintain and calibrate the equipment used in the alum treatment process?

- Follow manufacturer’s instructions for maintenance and calibration

- Use calibrated instruments to ensure accuracy

- Regularly check and clean equipment to prevent malfunctions

8. What are the environmental regulations related to alum use in water treatment?

Alum use is regulated to ensure that residual aluminum levels in treated water meet drinking water standards. Regulations may vary depending on the jurisdiction.

9. What is the role of alum in the coagulation process?

The role of alum in the coagulation process is to neutralize the negative charges on colloidal particles in water, causing them to aggregate and form flocs.

10. What are the benefits of using polyaluminum chloride (PAC) over aluminum sulfate?

- Higher efficiency in coagulation

- Lower residual aluminum levels

- Reduced sludge production

- Improved water clarity

- Easier handling and storage

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Alum Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Alum Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Alum Operators play a vital role in the water treatment process by operating and maintaining alum systems. Their primary responsibilities include:

1. Alum Coagulation and Flocculation

Operate alum feed systems to add the proper dosage of alum to the raw water.

- Monitor and adjust alum dosage based on raw water quality and plant operating conditions.

- Ensure effective coagulation and flocculation of impurities, resulting in the formation of larger particles.

2. Solids Removal and Disposal

Operate sedimentation basins and clarifiers to remove coagulated particles.

- Monitor solids accumulation and initiate sludge removal procedures.

- Supervise the disposal of alum sludge in accordance with environmental regulations.

3. Equipment Maintenance and Calibration

Maintain and calibrate alum feed pumps, flow meters, and other equipment used in the alum system.

- Troubleshoot and repair system malfunctions to ensure efficient operation.

- Perform regular inspections and preventive maintenance to prevent equipment failure.

4. Monitoring and Documentation

Monitor and record alum feed rates, pH levels, and other process parameters.

- Maintain accurate logs and reports to document system performance.

- Participate in water quality testing and analysis to optimize alum treatment.

Interview Tips

To prepare for an interview for an Alum Operator position, you should highlight your skills and experience in the following areas:

1. Technical Knowledge

Demonstrate a thorough understanding of alum coagulation and flocculation processes.

- Explain how alum dosage is determined and adjusted based on raw water quality.

- Describe the operation and maintenance of sedimentation basins and clarifiers.

2. Equipment Operation and Maintenance

Emphasize your experience in operating and maintaining alum feed systems, pumps, and related equipment.

- Provide examples of troubleshooting and repair procedures you have performed.

- Discuss your knowledge of preventive maintenance practices to ensure efficient equipment operation.

3. Process Monitoring and Control

Highlight your ability to monitor and control alum treatment processes effectively.

- Explain how you use monitoring data to optimize alum dosage and improve water quality.

- Describe your experience in maintaining accurate logs and reports to track system performance.

4. Safety and Regulations

Emphasize your knowledge of safety protocols and environmental regulations related to alum handling and disposal.

- Discuss your experience in complying with safety guidelines and adhering to regulatory requirements.

- Provide examples of how you ensure the proper disposal of alum sludge to minimize environmental impact.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Alum Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!