Are you gearing up for an interview for a Aluminum Boats Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Aluminum Boats Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

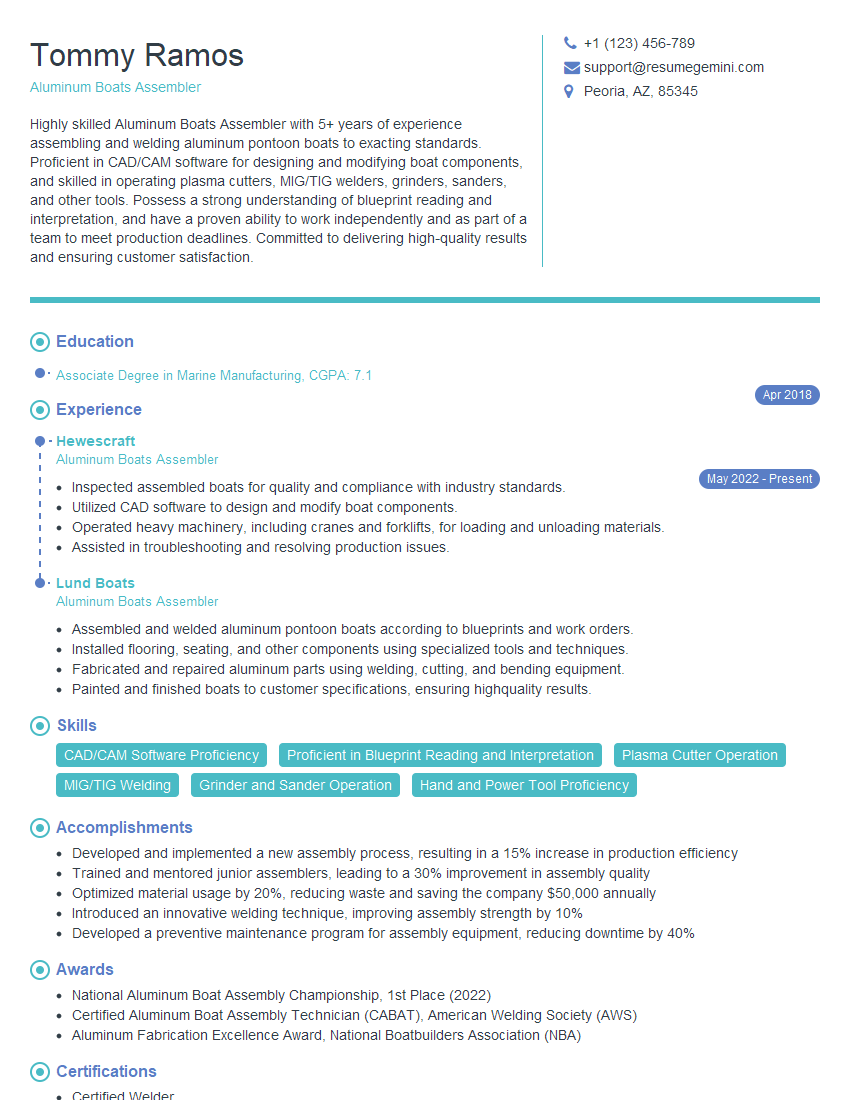

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aluminum Boats Assembler

1. What are the different types of aluminum used in boat construction?

There are several types of aluminum used in boat construction, each with its own advantages and disadvantages:

- 5052 Aluminum: This is a general-purpose aluminum alloy that is often used for boat hulls and decks. It is relatively strong and corrosion-resistant, but it is not as strong as some other aluminum alloys.

- 5086 Aluminum: This is a marine-grade aluminum alloy that is specifically designed for use in boat construction. It is stronger than 5052 aluminum and has better corrosion resistance, but it is also more expensive.

- 6061 Aluminum: This is an aerospace-grade aluminum alloy that is very strong and lightweight. It is often used for high-performance boats.

2. What are the different methods of joining aluminum sheets?

Welding

- MIG Welding (GMAW): Metal inert gas welding is a semi-automatic or automatic welding process that uses a shielding gas to protect the weld area from contamination.

- TIG Welding (GTAW): Tungsten inert gas welding is a manual welding process that uses a non-consumable tungsten electrode to create the weld.

Mechanical Joining

- Rivetting: Rivetting involves joining two pieces of aluminum together using a metal rivet.

- Bolting: Bolting involves joining two pieces of aluminum together using bolts and nuts.

Adhesive Bonding

- Structural Adhesive: Structural adhesives are used to bond two pieces of aluminum together by forming a strong chemical bond.

3. What are the key steps involved in assembling an aluminum boat?

- Cutting the aluminum sheets to the desired shape and size

- Joining the aluminum sheets together using the appropriate method

- Installing the necessary fittings and fixtures

- Testing the boat for leaks and other defects

4. What are the common problems that can occur during aluminum boat assembly?

- Leaks

- Cracks

- Corrosion

- Improperly installed fittings or fixtures

5. What safety precautions should be taken when assembling aluminum boats?

- Wear proper safety gear, including gloves, eye protection, and a welding mask.

- Work in a well-ventilated area.

- Be aware of the potential for electrical hazards.

- Follow all manufacturer’s instructions for the welding equipment and materials.

6. What are the different types of aluminum boat hulls?

- Flat Bottom Hull: This type of hull has a flat bottom and is typically used for smaller boats.

- V-Hull: This type of hull has a V-shaped bottom and is typically used for larger boats.

- Catamaran Hull: This type of hull has two hulls that are connected by a crossbeam.

- Trimaran Hull: This type of hull has three hulls that are connected by crossbeams.

7. What are the advantages and disadvantages of aluminum boat hulls?

Advantages

- Lightweight

- Strong

- Corrosion-resistant

- Durable

Disadvantages

- Can be more expensive than other materials

- Can be difficult to repair

8. What are the different types of aluminum boat decks?

- Bare Aluminum Deck: This type of deck is made from a single sheet of aluminum and is typically used for smaller boats.

- Tread Plate Deck: This type of deck is made from a sheet of aluminum that has been embossed with a pattern of ridges and grooves. It is typically used for larger boats.

- Composite Deck: This type of deck is made from a combination of aluminum and fiberglass or other materials. It is typically used for high-performance boats.

9. What are the advantages and disadvantages of aluminum boat decks?

Advantages

- Lightweight

- Strong

- Corrosion-resistant

- Durable

Disadvantages

- Can be slippery when wet

- Can be hot in the sun

10. What are the different types of aluminum boat fittings?

- Cleats: Cleats are used to tie the boat to a dock or other object.

- Fairleads: Fairleads are used to guide the rope or chain from the cleats to the bow or stern of the boat.

- Bow and Stern Eyes: Bow and stern eyes are used to attach the boat to a trailer or other object.

- Grab Rails: Grab rails are used to provide a secure handhold for passengers and crew.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aluminum Boats Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aluminum Boats Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Aluminum Boats Assembler is responsible for assembling, installing, and testing aluminum boats to ensure they meet quality and safety standards.

1. Material Preparation

Preparing aluminum sheets and parts for assembly by cutting, shaping, and bending.

- Reading blueprints and specifications to determine material requirements.

- Operating cutting, bending, and shaping machines to prepare materials.

2. Boat Assembly

Assembling aluminum boat hulls, decks, and other components using welding, riveting, and bolting techniques.

- Positioning and securing components according to specifications.

- Welding, riveting, and bolting components to form a watertight and structurally sound boat.

3. Final Assembly

Installing and testing boat accessories, such as engines, control systems, and electrical components.

- Installing engines, mounting brackets, and fuel systems.

- Connecting control cables, gauges, and electrical wiring.

4. Quality Control

Inspecting assembled boats for defects or errors and making necessary adjustments or repairs.

- Checking welds, rivets, and other joints for strength and durability.

- Testing boats on water to ensure they meet performance and safety standards.

Interview Tips

To prepare for an interview for an Aluminum Boats Assembler position, consider the following tips:

1. Research the Company and Position

Learn about the boat company’s history, products, and reputation. Research the specific role and its responsibilities.

- Visit the company’s website and read industry publications.

- Look for information on the company’s aluminum boat assembly process.

2. Highlight Relevant Skills and Experience

Emphasize your skills in aluminum welding, riveting, and boat assembly. Quantify your experience whenever possible.

- Describe projects or tasks where you demonstrated these skills.

- Provide specific examples of boats you have assembled.

3. Show Your Passion for Boats

Explain your interest in aluminum boats and why you enjoy working with them. Describe your favorite type of boat and why.

- Share personal experiences or hobbies related to boats.

- Discuss your knowledge of different boat designs and materials.

4. Prepare for Technical Questions

Expect questions about aluminum boat construction, welding techniques, and safety procedures. Be prepared to discuss your understanding of these topics.

- Review common welding methods used in boat assembly.

- Research industry standards for boat safety and quality control.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aluminum Boats Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.