Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Aluminum Container Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

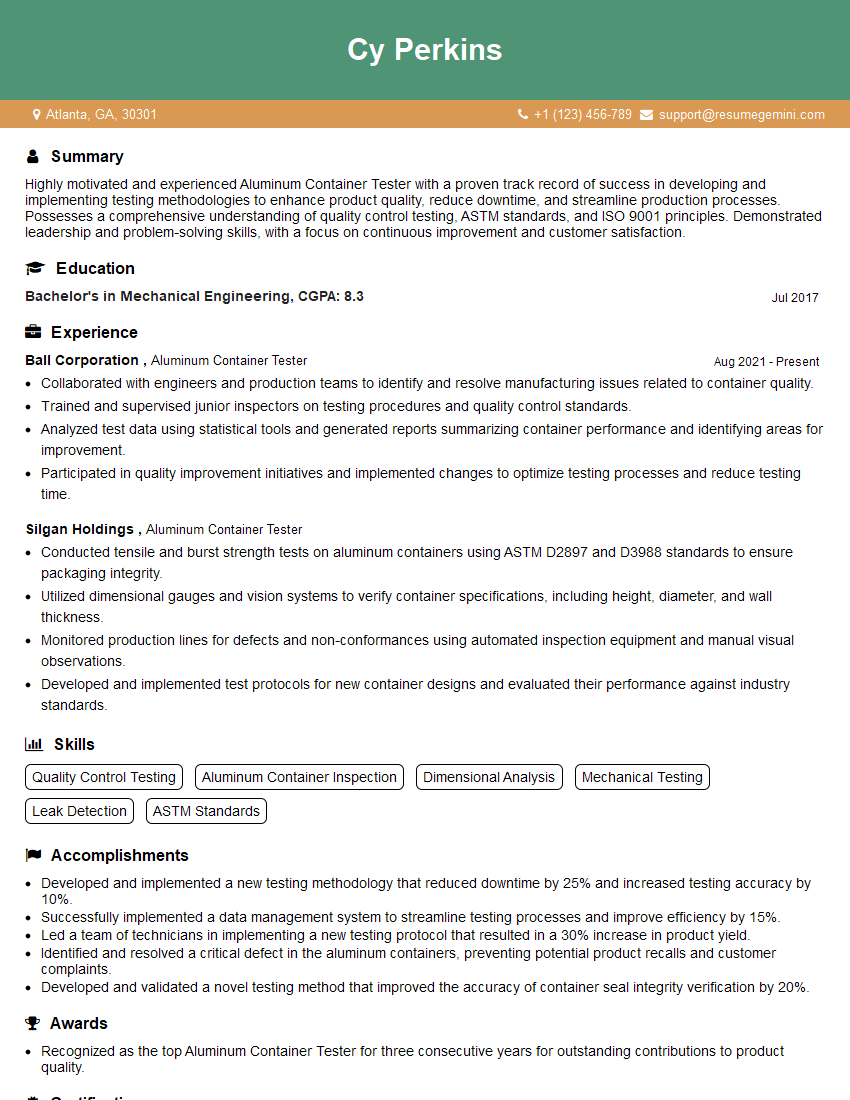

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aluminum Container Tester

1. Describe the steps involved in testing the seam integrity of aluminum containers.

The steps involved in testing the seam integrity of aluminum containers are as follows:

- Visual inspection: The container is visually inspected for any obvious defects, such as cracks, tears, or punctures.

- Pressure testing: The container is filled with air or water and pressurized to a predetermined level. The container is then held under pressure for a specified period of time to check for any leaks.

- Leak testing: The container is submerged in water and pressurized with air or water. The container is then inspected for any bubbles, which would indicate a leak.

- Non-destructive testing: Non-destructive testing methods, such as ultrasonic testing or X-ray inspection, can be used to detect any internal defects in the container.

2. What are the different types of aluminum container tests that can be performed?

- Physical tests: Physical tests measure the physical properties of the container, such as its strength, rigidity, and durability.

- Chemical tests: Chemical tests measure the chemical composition of the container to ensure that it meets the required specifications.

- Functional tests: Functional tests assess the performance of the container in its intended use, such as its ability to hold and dispense its contents.

- Environmental tests: Environmental tests simulate the conditions that the container will be exposed to in its intended use, such as temperature extremes, humidity, and vibration.

3. What are the most common defects that you have encountered in aluminum containers?

- Seam defects: Seam defects are the most common type of defect in aluminum containers. These defects can occur due to a variety of factors, such as improper welding, contamination, or damage.

- Material defects: Material defects are another common type of defect in aluminum containers. These defects can occur due to a variety of factors, such as impurities in the aluminum, or improper heat treatment.

- Design defects: Design defects are defects that are caused by the design of the container. These defects can occur due to a variety of factors, such as poor engineering, or insufficient testing.

4. What are the different types of equipment that you use to test aluminum containers?

- Pressure testers: Pressure testers are used to test the seam integrity of aluminum containers.

- Leak testers: Leak testers are used to detect any leaks in aluminum containers.

- Non-destructive testing equipment: Non-destructive testing equipment, such as ultrasonic testing or X-ray inspection, can be used to detect any internal defects in aluminum containers.

- Dimensional measuring equipment: Dimensional measuring equipment is used to measure the dimensions of aluminum containers to ensure that they meet the required specifications.

5. What are the quality control procedures that you follow when testing aluminum containers?

- Visual inspection: All aluminum containers are visually inspected for any obvious defects, such as cracks, tears, or punctures.

- Pressure testing: All aluminum containers are pressure tested to ensure that they meet the required specifications.

- Leak testing: All aluminum containers are leak tested to ensure that they are free of any leaks.

- Dimensional measuring: All aluminum containers are dimensionally measured to ensure that they meet the required specifications.

6. What are the safety precautions that you take when testing aluminum containers?

- Always wear appropriate safety gear, such as gloves, safety glasses, and a lab coat.

- Never test aluminum containers that are damaged or have any obvious defects.

- Always test aluminum containers in a well-ventilated area.

- Never expose aluminum containers to open flames or high temperatures.

7. What are the industry standards that you are familiar with for testing aluminum containers?

- ASTM International: ASTM International is a global standards organization that develops and publishes standards for a wide range of materials, including aluminum containers.

- International Organization for Standardization (ISO): ISO is a global standards organization that develops and publishes standards for a wide range of products and services, including aluminum containers.

- British Standards Institution (BSI): BSI is a national standards organization in the United Kingdom that develops and publishes standards for a wide range of products and services, including aluminum containers.

8. What are the challenges that you have faced in testing aluminum containers?

- Defects can be difficult to detect: Defects in aluminum containers can be difficult to detect, especially if they are small or internal.

- Testing can be time-consuming: Testing aluminum containers can be time-consuming, especially if a large number of containers need to be tested.

- Testing can be expensive: Testing aluminum containers can be expensive, especially if specialized equipment is required.

9. What are the trends that you are seeing in the testing of aluminum containers?

- Increased use of automation: Automation is being increasingly used to test aluminum containers, which can improve efficiency and accuracy.

- Increased use of non-destructive testing: Non-destructive testing is being increasingly used to test aluminum containers, as it can detect defects without damaging the container.

- Increased use of online testing: Online testing is being increasingly used to test aluminum containers, as it can provide real-time feedback on the quality of the containers.

10. What are the future challenges that you see in the testing of aluminum containers?

- The need to test for new types of defects: As new technologies are developed, new types of defects can emerge in aluminum containers.

- The need to test for smaller defects: As the quality of aluminum containers continues to improve, the need to test for smaller defects will increase.

- The need to test containers faster and more efficiently: As the demand for aluminum containers continues to grow, the need to test containers faster and more efficiently will increase.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aluminum Container Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aluminum Container Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aluminum Container Testers are responsible for ensuring the quality and safety of aluminum containers. They perform a variety of tests to check for defects, leaks, and other problems. They also work with engineers and other quality control personnel to develop and improve testing methods.

1. Conduct physical tests on aluminum containers

To ensure that aluminum containers meet the required specifications, Aluminum Container Testers perform various physical tests. These tests may include:

- Dimensional measurements: Testers check the dimensions of containers to ensure they meet the specified requirements. This involves measuring the length, width, height, and other dimensions of the container.

- Weight measurements: Aluminum Container Testers also check the weight of containers to ensure they meet the specified requirements. This involves weighing the container and comparing it to the specified weight range.

- Leak testing: Leak testing is performed to ensure that containers are free from leaks. Testers use various methods to check for leaks, such as water immersion testing or pressure testing. This ensures that the containers can safely hold the intended contents without any leakage.

2. Conduct chemical tests on aluminum containers

In addition to physical tests, Aluminum Container Testers also perform chemical tests to ensure the quality of the aluminum used in the containers. These tests may include:

- Composition analysis: Testers analyze the chemical composition of the aluminum to ensure it meets the required specifications. This involves determining the percentages of different elements present in the aluminum, such as iron, silicon, and manganese.

- Coating analysis: Aluminum containers often have a protective coating to prevent corrosion. Testers analyze the coating to ensure it is applied properly and meets the required thickness and quality standards.

3. Maintain and calibrate testing equipment

To ensure accurate and reliable test results, Aluminum Container Testers are responsible for maintaining and calibrating the testing equipment. This may include:

- Regular maintenance: Testers perform regular maintenance on the testing equipment, such as cleaning, lubricating, and replacing worn parts. This ensures that the equipment is in good working condition and produces accurate results.

- Calibration: Testers also calibrate the testing equipment to ensure it is measuring correctly. This involves comparing the equipment’s readings to a known standard and making any necessary adjustments.

4. Document test results and prepare reports

After conducting the tests, Aluminum Container Testers document the results and prepare reports. These reports typically include:

- Test results: The reports include the results of all the tests performed, such as the dimensional measurements, weight measurements, leak test results, and chemical analysis results.

- Interpretation of results: The reports also include an interpretation of the results, which may include a statement on whether the containers meet the specified requirements or not.

- Recommendations: The reports may also include recommendations for corrective actions if any non-conformance is found.

Interview Tips

Preparing for an interview as an Aluminum Container Tester requires a thorough understanding of the key job responsibilities and the specific skills and qualifications required for the role. To ace the interview, it is essential to showcase your knowledge, experience, and enthusiasm for the field. Here are a few tips to help you prepare for your interview:

1. Research the company and the position

Before the interview, take some time to research the company you are applying to and the specific position you are interested in. This will help you understand the company’s culture, values, and the specific requirements of the role. You can visit the company’s website, read industry news, and talk to people in your network who have worked there. This knowledge will allow you to tailor your answers to the interviewer’s questions and demonstrate your genuine interest in the position.

2. Practice answering common interview questions

There are some common interview questions that you are likely to encounter in an interview for an Aluminum Container Tester position. It is helpful to practice answering these questions in advance so you can deliver clear and concise responses during the interview. Some common questions include:

- Tell me about your experience in testing aluminum containers.

- What are some of the most important quality control measures for aluminum containers?

- How do you ensure the accuracy and reliability of your test results?

- What are some of the challenges you have faced in your previous role as an Aluminum Container Tester?

- Why are you interested in this position at our company?

3. Highlight your skills and experience

During the interview, be sure to highlight your skills and experience that are relevant to the position of Aluminum Container Tester. This may include your experience in conducting physical and chemical tests on aluminum containers, as well as your knowledge of industry standards and regulations. You can also mention any relevant certifications or training you have completed.

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are engaged and interested in the opportunity. Some good questions to ask include:

- What are the most important qualities you are looking for in an Aluminum Container Tester?

- What are the biggest challenges facing the company right now?

- What is the company culture like?

- What are the opportunities for advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aluminum Container Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!