Feeling lost in a sea of interview questions? Landed that dream interview for Aluminum Fabrication Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Aluminum Fabrication Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

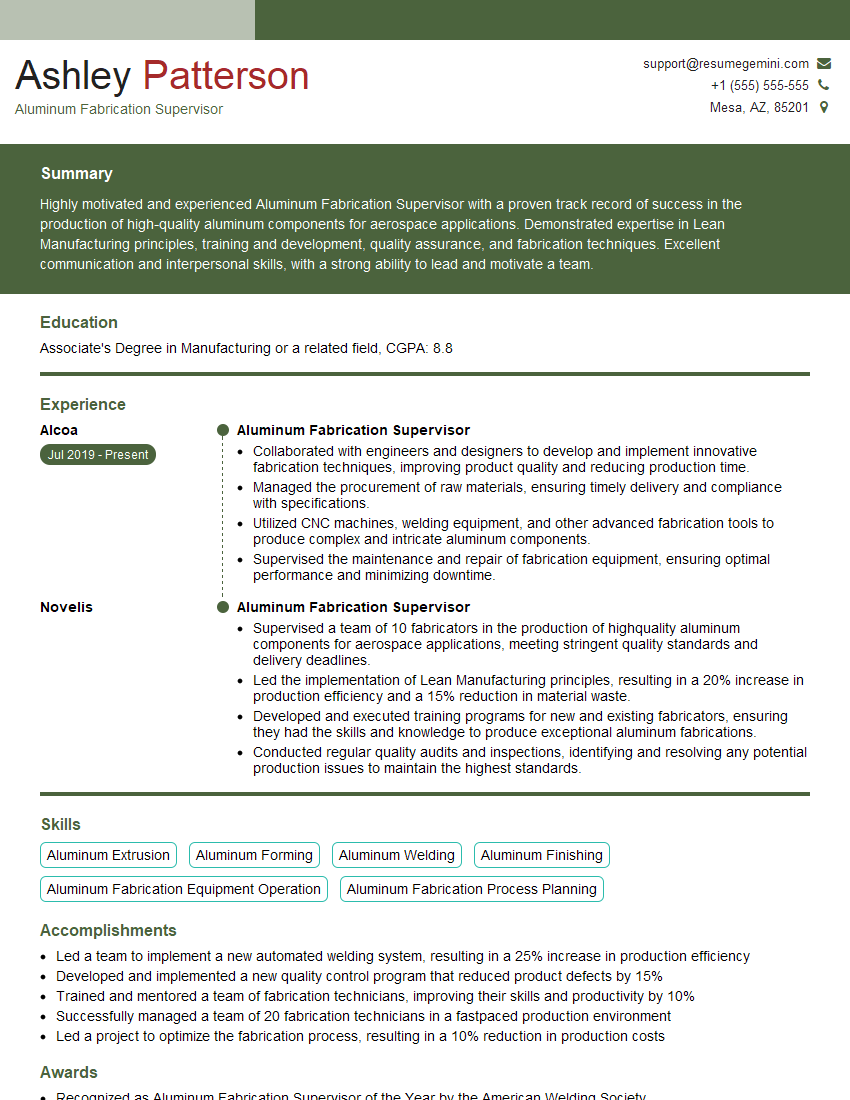

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aluminum Fabrication Supervisor

1. How would you ensure that the aluminum fabrication process meets the specified tolerances and quality standards?

- Review design specifications and identify critical dimensions and tolerances.

- Implement quality control measures throughout the fabrication process, including regular inspections and testing.

- Utilize precision measuring tools and techniques to ensure accuracy.

- Monitor process parameters and make adjustments as needed to maintain consistent quality.

- Provide training to fabricators on quality control procedures.

2. What techniques would you use to identify and resolve common defects in aluminum fabrication, such as porosity, cracks, and warpage?

Causes of Defects

- Porosity: Entrapment of gas during casting or welding.

- Cracks: Stress concentration, improper welding techniques.

- Warpage: Uneven cooling or heating, improper support during heat treatment.

Inspection Techniques

- Visual inspection, penetrant testing, ultrasonic testing.

Resolution Techniques

- Porosity: Remelting or welding to fill the voids.

- Cracks: Repair by welding or grinding and rewelding.

- Warpage: Realignment, straightening, or heat treatment.

3. How would you optimize the use of aluminum materials and minimize waste in the fabrication process?

- Plan material utilization to minimize scrap and offcuts.

- Use nesting software to optimize material placement and reduce waste.

- Explore alternative materials or processes that generate less waste.

- Implement recycling programs for aluminum scrap.

- Train fabricators on efficient material handling practices.

4. What safety precautions would you implement in an aluminum fabrication facility to mitigate potential hazards such as dust, fumes, and welding operations?

- Provide proper ventilation and exhaust systems to remove dust and fumes.

- Enforce the use of personal protective equipment (PPE), including respirators, gloves, and safety glasses.

- Establish safe welding practices, including proper ventilation, protective gear, and fire safety measures.

- Train employees on safety protocols and hazard identification.

- Conduct regular safety inspections and audits.

5. How would you lead and motivate a team of aluminum fabricators to achieve production targets and maintain quality standards?

- Set clear goals and expectations, and communicate them effectively.

- Provide regular feedback and recognition to acknowledge accomplishments.

- Foster a positive and collaborative work environment.

- Empower team members and delegate responsibilities.

- Address performance issues promptly and provide support for improvement.

6. Describe your experience in implementing lean manufacturing principles or other process improvement methodologies in an aluminum fabrication environment.

- Value stream mapping to identify waste and inefficiencies.

- Kanban systems for inventory management and just-in-time production.

- Total productive maintenance (TPM) to maximize equipment uptime.

- Continuous improvement (Kaizen) through employee engagement and suggestion programs.

- Data analysis and process monitoring for performance evaluation and optimization.

7. What software or tools do you have experience in using for aluminum fabrication operations, such as CAD/CAM, ERP, or quality control software?

- CAD/CAM: SolidWorks, AutoCAD, Mastercam.

- ERP: SAP, Oracle NetSuite, Epicor.

- Quality Control: Dimensional inspection software, SPC software.

- Fabrication Management: ProFab, FabSuite, CNC Software.

8. Describe your experience in developing and managing maintenance schedules for aluminum fabrication equipment.

- Create preventive maintenance schedules based on equipment specifications and usage.

- Implement condition-based maintenance using predictive analytics.

- Schedule downtime for major maintenance and repairs during non-production hours.

- Maintain records of maintenance activities and track equipment performance.

- Train maintenance technicians on proper equipment care and troubleshooting.

9. How would you ensure compliance with industry regulations and standards, such as ISO 9001 and AWS D1.2, in aluminum fabrication?

- Establish a quality management system that meets ISO 9001 requirements.

- Implement documented procedures for all key processes.

- Train employees on quality control standards and regulations.

- Conduct regular internal audits to assess compliance.

- Participate in external certifications and assessments.

10. How would you stay abreast of advancements and best practices in aluminum fabrication techniques?

- Attend industry conferences and trade shows.

- Read technical journals and publications.

- Participate in online forums and discussion groups.

- Network with other professionals in the field.

- Conduct in-house research and development projects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aluminum Fabrication Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aluminum Fabrication Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Aluminum Fabrication Supervisor is a critical role within the organization, responsible for overseeing the entire process of fabricating aluminum products. They are accountable for ensuring that all operations are carried out efficiently and effectively, maintaining high standards of quality while adhering to safety regulations.

1. Production Planning and Management

The supervisor plans and schedules production activities, ensuring that all orders are completed on time and to specifications. They allocate resources, including personnel, equipment, and materials, to optimize production flow and minimize downtime.

- Develop and implement production schedules to meet customer demand.

- Assign tasks and responsibilities to team members to ensure efficient workflow.

- Monitor production progress and make adjustments as needed to meet deadlines.

2. Quality Control and Assurance

The supervisor is responsible for maintaining high standards of quality throughout the fabrication process. They inspect products at various stages of production to ensure they meet specifications and customer requirements.

- Develop and implement quality control procedures to ensure product quality.

- Inspect products at key stages of the production process to identify and address defects.

- Work closely with the quality assurance team to ensure compliance with industry standards.

3. Equipment Maintenance and Management

The supervisor is responsible for ensuring that all equipment used in fabrication is well-maintained and operating at optimal levels. They oversee maintenance schedules, identify and resolve equipment issues, and coordinate repairs as needed.

- Develop and implement equipment maintenance schedules to prevent breakdowns.

- Inspect and troubleshoot equipment to identify and resolve issues promptly.

- Coordinate with maintenance personnel to perform repairs and ensure equipment reliability.

4. Team Management and Supervision

The supervisor leads and motivates a team of fabrication workers, providing guidance, training, and support. They ensure that all team members are adequately trained and follow safety procedures.

- Lead, motivate, and develop a team of fabrication workers.

- Provide training and guidance to team members to enhance their skills and knowledge.

- Enforce safety regulations and ensure a safe work environment for the team.

Interview Tips

Preparing for an interview for the role of Aluminum Fabrication Supervisor requires a well-rounded approach that encompasses both technical expertise and leadership abilities. Here are some valuable tips to help you ace the interview:

1. Research the Company and Industry

Take the time to thoroughly research the company and the aluminum fabrication industry. This will provide you with insights into the company’s culture, values, and market position. Understanding industry trends and best practices will demonstrate your knowledge and interest in the field.

- Visit the company’s website, read industry publications, and attend relevant events.

- Identify key industry players and their competitive landscape.

- Familiarize yourself with the company’s products, services, and customer base.

2. Highlight Your Technical Expertise

Emphasize your technical knowledge and experience in aluminum fabrication. Discuss your understanding of the different fabrication processes, such as cutting, bending, welding, and finishing. Showcase your ability to read and interpret technical drawings and specifications.

- Provide examples of complex projects you have successfully supervised.

- Quantify your accomplishments whenever possible, using metrics such as improved quality, reduced production time, or increased efficiency.

- Discuss your knowledge of industry standards and regulatory compliance.

3. Showcase Your Leadership and Management Skills

Highlight your leadership and management capabilities. Describe your experience in leading, motivating, and developing teams. Emphasize your ability to create a positive and productive work environment.

- Provide examples of how you have successfully managed and resolved conflicts within a team.

- Share your strategies for employee training and development.

- Discuss your approach to maintaining a safe and compliant work environment.

4. Prepare Industry-Specific Questions

Prepare industry-specific questions to ask the interviewer. This demonstrates your knowledge and interest in the field. Ask about the company’s current projects, industry challenges, or the latest technological advancements in aluminum fabrication.

- Inquire about the company’s growth plans and how your skills can contribute to their success.

- Ask about their commitment to quality and innovation.

- Show interest in the company’s environmental sustainability practices.

5. Practice Your Answers and Prepare Examples

Practice answering common interview questions and prepare specific examples to support your claims. This will help you respond confidently and concisely during the interview. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples that demonstrate your skills and experience.

- Anticipate questions related to your technical expertise, leadership abilities, and industry knowledge.

- Prepare examples that highlight your problem-solving, decision-making, and conflict resolution skills.

- Practice your answers to ensure they are clear, concise, and engaging.

Next Step:

Now that you’re armed with the knowledge of Aluminum Fabrication Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Aluminum Fabrication Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini