Are you gearing up for a career in Aluminum Hydroxide Process Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Aluminum Hydroxide Process Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

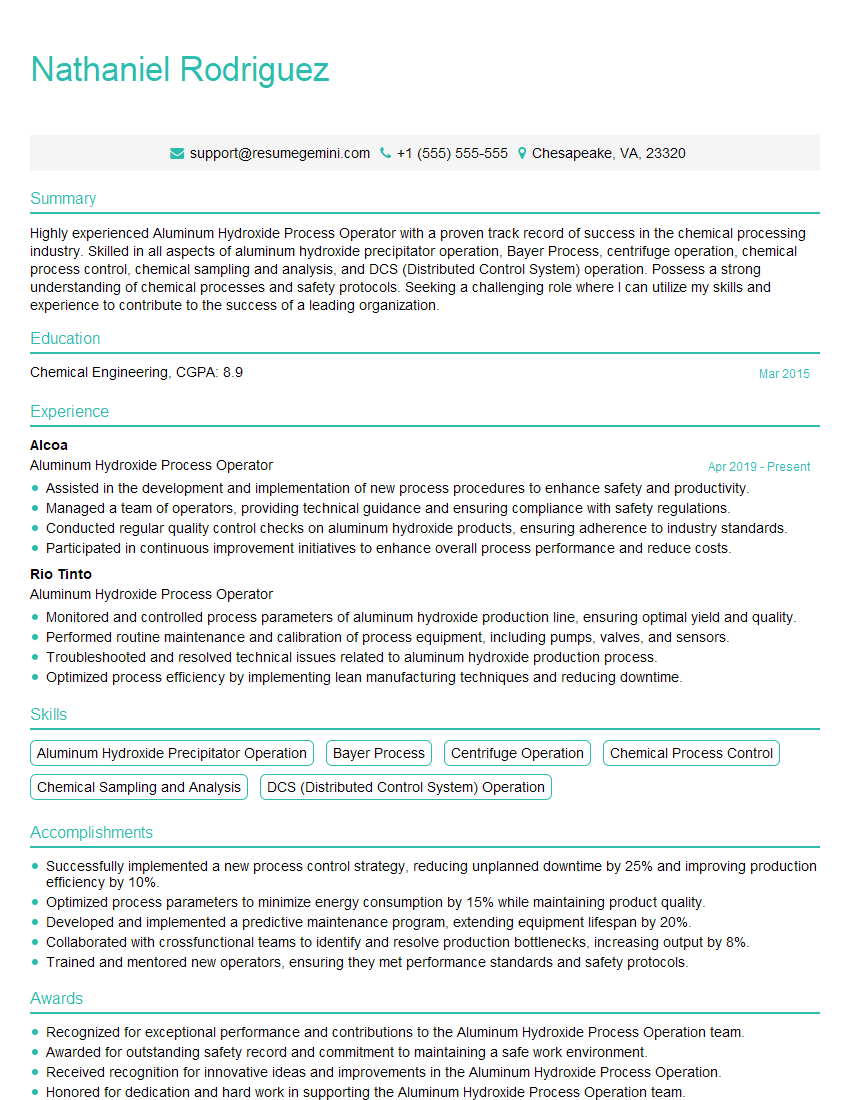

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aluminum Hydroxide Process Operator

1. Explain the key steps involved in the Aluminum Hydroxide process?

The main steps in the Aluminum Hydroxide process include:

- Bauxite Extraction: Mining and crushing bauxite ore to obtain the raw material.

- Bayer Process: Dissolving bauxite in a sodium hydroxide solution, separating impurities, and precipitating Aluminum Hydroxide.

- Calcination: Heating Aluminum Hydroxide to release water and form Aluminum Oxide (Alumina).

- Electrolysis: Passing an electric current through molten Alumina to produce Aluminum metal.

2. Describe the role of caustic soda in the precipitation of Aluminum Hydroxide?

Importance of Caustic Soda

- Dissolves Bauxite to extract Aluminum compounds.

- Promotes the formation of Sodium Aluminate, which is necessary for precipitation.

Precipitation Process

- When the Sodium Aluminate solution is cooled, it becomes supersaturated with Aluminum Hydroxide.

- Adding seed crystals (small Aluminum Hydroxide particles) initiates the precipitation process.

- The Aluminum Hydroxide crystals grow and settle at the bottom of the precipitation tank.

3. What are the critical operating parameters to monitor in the precipitation stage?

To ensure efficient precipitation, it is important to monitor the following parameters:

- Temperature: Controls the solubility of Aluminum Hydroxide and the precipitation rate.

- pH: Affects the stability of Sodium Aluminate and the formation of Aluminum Hydroxide crystals.

- Caustic Soda Concentration: Influences the solubility of Aluminum compounds and the precipitation process.

- Impurity Levels: Monitoring impurities like Silica and Iron is crucial to prevent contamination of Aluminum Hydroxide.

4. Explain the methods used to separate Aluminum Hydroxide from the spent liquor?

The separation of Aluminum Hydroxide from spent liquor typically involves the following methods:

- Thickening: Allowing Aluminum Hydroxide to settle and thicken in thickeners.

- Filtration: Using vacuum filters or pressure filters to separate solids from liquid.

- Washing: Rinsing the Aluminum Hydroxide with water to remove impurities and residual liquor.

- Drying: Using dryers to remove moisture from Aluminum Hydroxide before calcination.

5. Describe the importance of calcination in the production of Aluminum Oxide?

Calcination is a crucial step because:

- Dehydration: Removes water molecules from Aluminum Hydroxide to form Aluminum Oxide.

- Crystallization: Transforms the amorphous Aluminum Hydroxide into crystalline Aluminum Oxide, which is more stable and suitable for electrolysis.

- Shrinkage: Reduces the volume of Aluminum Hydroxide, making it easier to handle and transport.

- Impurity Removal: Further removes impurities present in Aluminum Hydroxide.

6. What are the key quality control measures implemented to ensure the purity of Aluminum Hydroxide?

Quality control measures include:

- Sampling and Analysis: Regularly sampling and analyzing Aluminum Hydroxide at different stages to monitor its composition.

- Impurity Testing: Testing for impurities like Silica, Iron, and heavy metals to ensure they meet specifications.

- Particle Size Control: Monitoring the particle size distribution of Aluminum Hydroxide for optimal performance in downstream processes.

- Moisture Content: Controlling the moisture content to prevent agglomeration and ensure proper handling.

7. Explain the safety precautions and emergency procedures related to the handling of Aluminum Hydroxide?

Safety precautions and emergency procedures include:

- Dust Control: Minimizing dust exposure by using enclosed systems, respirators, and proper ventilation.

- Chemical Resistance: Using chemically resistant materials in equipment handling Aluminum Hydroxide.

- Spill Response: Having designated spill kits and procedures to clean up spills promptly and safely.

- Fire Prevention: Implementing measures to prevent fires, such as eliminating ignition sources and using non-flammable materials.

8. Describe the environmental regulations and sustainability practices associated with Aluminum Hydroxide production?

Environmental regulations and sustainability practices include:

- Wastewater Treatment: Ensuring that wastewater from the process meets environmental standards.

- Solid Waste Management: Implementing waste minimization and recycling programs.

- Energy Efficiency: Optimizing energy consumption throughout the process to reduce environmental impact.

- Compliance with Regulations: Adhering to local, national, and international environmental regulations.

9. What are the potential career advancement opportunities for an Aluminum Hydroxide Process Operator?

Career advancement opportunities may include:

- Senior Process Operator: Supervising a team of operators and ensuring the efficient operation of the plant.

- Process Engineer: Designing and optimizing Aluminum Hydroxide processes for improved efficiency and sustainability.

- Plant Manager: Managing the overall operations of an Aluminum Hydroxide production facility.

- Technical Specialist: Providing expertise in Aluminum Hydroxide production and process optimization.

10. How can your skills and experience contribute to the success of our Aluminum Hydroxide production team?

My skills and experience can benefit your team in several ways:

- Proven Expertise: I have a strong understanding of Aluminum Hydroxide production processes, including precipitation, filtration, and calcination.

- Optimization Mindset: I am constantly seeking ways to improve efficiency, reduce waste, and enhance product quality.

- Teamwork and Communication: I am an effective communicator and collaborator, fostering a positive and productive work environment.

- Safety and Compliance: I am committed to maintaining a safe and compliant work area, ensuring the well-being of my colleagues and the protection of the environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aluminum Hydroxide Process Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aluminum Hydroxide Process Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Aluminum Hydroxide Process Operator is responsible for operating and maintaining the aluminum hydroxide production process. This includes:

1. Operating the production process

This involves monitoring the process, making adjustments to the process parameters, and ensuring that the process is running smoothly and efficiently.

- Monitoring the process parameters, such as temperature, pressure, and flow rates.

- Making adjustments to the process parameters, as needed, to ensure that the process is running smoothly and efficiently.

- Troubleshooting and resolving any problems that may occur during the process.

2. Maintaining the production process

This involves performing routine maintenance tasks, such as cleaning the equipment, calibrating the instruments, and replacing the parts.

- Performing routine maintenance tasks, such as cleaning the equipment, calibrating the instruments, and replacing the parts.

- Inspecting the equipment for any signs of wear or damage.

- Repairing or replacing any damaged equipment.

3. Quality control

This involves testing the aluminum hydroxide product to ensure that it meets the required specifications.

- Testing the aluminum hydroxide product to ensure that it meets the required specifications.

- Maintaining records of the test results.

- Reporting any deviations from the required specifications to the supervisor.

4. Safety

This involves following all safety procedures and regulations, and ensuring that the workplace is safe for all employees.

- Following all safety procedures and regulations.

- Ensuring that the workplace is safe for all employees.

- Reporting any safety hazards to the supervisor.

Interview Tips

To prepare for your interview for an Aluminum Hydroxide Process Operator position, you can follow these tips:

1. Research the company and the position

This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the Aluminum Hydroxide Process Operator position.

- Visit the company’s website to learn more about its history, products, and services.

- Read industry news and articles to learn about the latest trends and developments in the aluminum hydroxide industry.

- Talk to people in your network who work in the aluminum hydroxide industry.

2. Practice your answers to common interview questions

This will help you feel more confident and prepared during your interview.

- Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with the aluminum hydroxide production process?

- How do you handle stress?

- What are your salary expectations?

3. Dress professionally

This will show the interviewer that you are serious about the position and that you respect the company.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Accessorize with a tie or scarf.

4. Be on time for your interview

This shows the interviewer that you are respectful of their time.

- Plan your route to the interview location in advance.

- Allow yourself plenty of time to get there.

- If you are running late, call the interviewer and let them know.

5. Be prepared to ask questions

This shows the interviewer that you are interested in the position and that you are engaged in the conversation.

- Some good questions to ask include:

- What are the challenges of the Aluminum Hydroxide Process Operator position?

- What are the opportunities for advancement?

- What is the company’s culture like?

Next Step:

Now that you’re armed with the knowledge of Aluminum Hydroxide Process Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Aluminum Hydroxide Process Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini