Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Aluminum Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

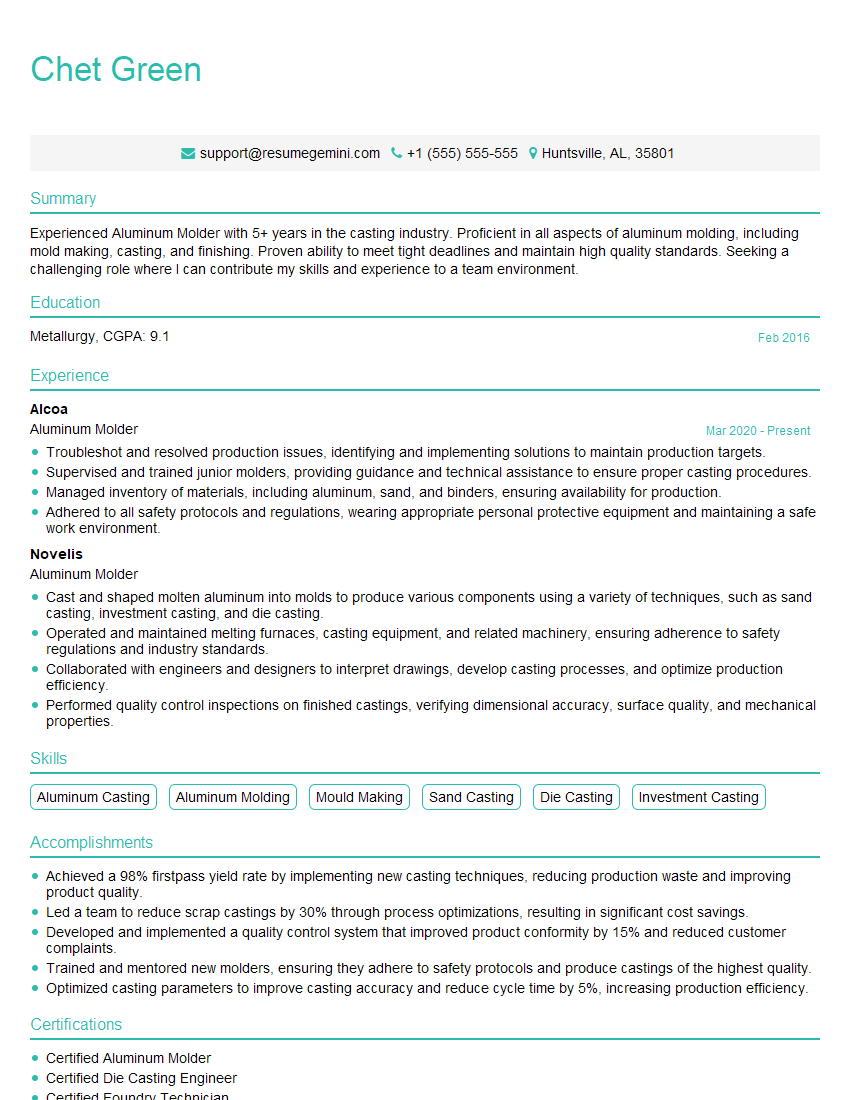

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aluminum Molder

1. What are the key differences between sand casting and permanent mold casting?

In sand casting, a sand mold is created for each casting, while in permanent mold casting, a metal mold is used. Sand casting is less precise than permanent mold casting, but it is also less expensive. Permanent mold casting is more precise, but it is also more expensive.

2. What are the different types of aluminum alloys used in casting?

Common Aluminum Alloys

- 1000 Series: Non-heat-treatable, good corrosion resistance

- 2000 Series: Heat-treatable, high strength

- 3000 Series: Non-heat-treatable, corrosion-resistant, good weldability

- 4000 Series: Non-heat-treatable, high strength

- 5000 Series: Heat-treatable, good corrosion resistance, weldability

Factors Affecting Alloy Selection

- Mechanical properties

- Casting process

- Corrosion resistance

- Weldability

3. What are the important considerations for designing a mold for aluminum casting?

The mold must be designed to allow for the proper flow of molten aluminum. It must also be designed to minimize the risk of defects, such as porosity and cold shuts. The mold must be made of a material that can withstand the high temperatures of molten aluminum.

4. What are the common defects that can occur in aluminum castings?

- Porosity: Holes or voids in the casting

- Cold shuts: Unfused areas in the casting

- Hot tears: Cracks that form during cooling

- Shrinkage: Distortion or cracking due to uneven cooling

- Slag inclusions: Pieces of foreign material trapped in the casting

5. What are the different methods of melting aluminum for casting?

Furnace Melting

- Electric resistance furnace

- Gas-fired furnace

- Induction furnace

Crucible Melting

- Tilting crucible furnace

- Stationary crucible furnace

6. What are the safety precautions that must be taken when working with molten aluminum?

Molten aluminum can cause serious burns. It is important to wear proper protective clothing, such as gloves, apron, and safety glasses. The work area should be well-ventilated to prevent the inhalation of fumes. Proper handling of molten aluminum is crucial to avoid accidents.

7. What are the different methods of degassing aluminum for casting?

Vacuum Degassing

- Removes hydrogen and other gases by creating a vacuum

Fluxing

- Removes oxides and other impurities by using a fluxing agent

Inert Gas Purging

- Injects an inert gas, such as nitrogen or argon, to remove dissolved gases

8. What are the different types of casting machines used for aluminum casting?

Gravity Casting

- Molten aluminum flows into the mold under its own weight

Pressure Casting

- Molten aluminum is forced into the mold under pressure

Centrifugal Casting

- Mold is spun rapidly, forcing molten aluminum to the outer edges

9. What are the different types of heat treatment processes used for aluminum castings?

Annealing

- Softens the casting by heating and slowly cooling

Solution Treatment

- Dissolves alloying elements to improve strength and toughness

Aging

- Precipitates alloying elements to further strengthen the casting

10. What are the different types of quality control tests performed on aluminum castings?

Dimensional Inspection

- Ensures castings meet specified dimensions

Visual Inspection

- Checks for surface defects, such as cracks and porosity

Radiographic Inspection

- Uses X-rays to detect internal defects

Ultrasonic Inspection

- Uses sound waves to detect internal defects

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aluminum Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aluminum Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aluminum Molders are responsible for a wide range of tasks in the manufacturing process of aluminum products. Their primary duties involve using specialized equipment and techniques to shape molten aluminum into various forms, ensuring that the end products meet the desired specifications and quality standards.

1. Mold Preparation

Molders prepare the molds by assembling and aligning the mold equipment according to the production specifications. They inspect the molds for defects and make necessary adjustments to ensure smooth casting operations.

- Assemble and align mold equipment

- Inspect molds for defects

- Make necessary adjustments to molds

2. Melting and Pouring

Molders are responsible for melting aluminum in furnaces and pouring the molten metal into the prepared molds. They control the temperature and composition of the molten metal to achieve the desired properties in the final product.

- Melt aluminum in furnaces

- Pour molten metal into molds

- Control temperature and composition

3. Casting and Solidification

Once the molten metal is poured into the molds, molders monitor the casting process to ensure proper solidification and cooling. They adjust equipment settings, such as pressure and temperature, to control the cooling rate and prevent defects in the castings.

- Monitor casting process

- Ensure proper solidification and cooling

- Adjust equipment settings for cooling rate

4. Post-Casting Operations

After the castings have solidified, molders perform post-casting operations to remove the castings from the molds, clean and inspect them for defects. They also perform finishing operations, such as grinding and polishing, to meet product specifications.

- Remove castings from molds

- Clean and inspect castings

- Perform finishing operations

Interview Tips

To ace the interview for an Aluminum Molder position, candidates should prepare thoroughly and highlight their skills and experience that align with the job requirements. Here are some interview tips and preparation hacks:

1. Research the Company and Industry

Before the interview, take the time to research the company and the aluminum manufacturing industry. Learn about their products, processes, and market position. This knowledge will demonstrate your interest in the company and the role, and help you tailor your answers to the specific requirements of the position.

- Visit the company website

- Read industry news and articles

- Attend industry events

2. Highlight Relevant Skills and Experience

Review the job description carefully to identify the key skills and experience required for the role. Tailor your resume and interview answers to showcase how your skills and experience match these requirements. Quantify your accomplishments and provide specific examples to demonstrate your capabilities.

- Prepare examples of successful mold preparation, casting, and post-casting operations

- Quantify your results, such as increased productivity or reduced defect rates

- Highlight your knowledge of aluminum alloys, mold design, and casting techniques

3. Practice Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivations. Prepare concise and well-articulated answers that highlight your strengths and fit for the position. Consider using the STAR method to structure your answers and provide specific examples.

- Tell me about your experience in aluminum molding?

- Describe a time when you had to solve a problem in the casting process?

- How do you ensure the quality and accuracy of your castings?

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions related to the company, the role, or the industry that show you have done your research and are genuinely interested in the opportunity.

- What are the company’s growth plans for the aluminum molding department?

- What opportunities are there for professional development within the company?

- How does the company ensure the safety and well-being of its employees?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aluminum Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.