Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Aluminum Molding Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

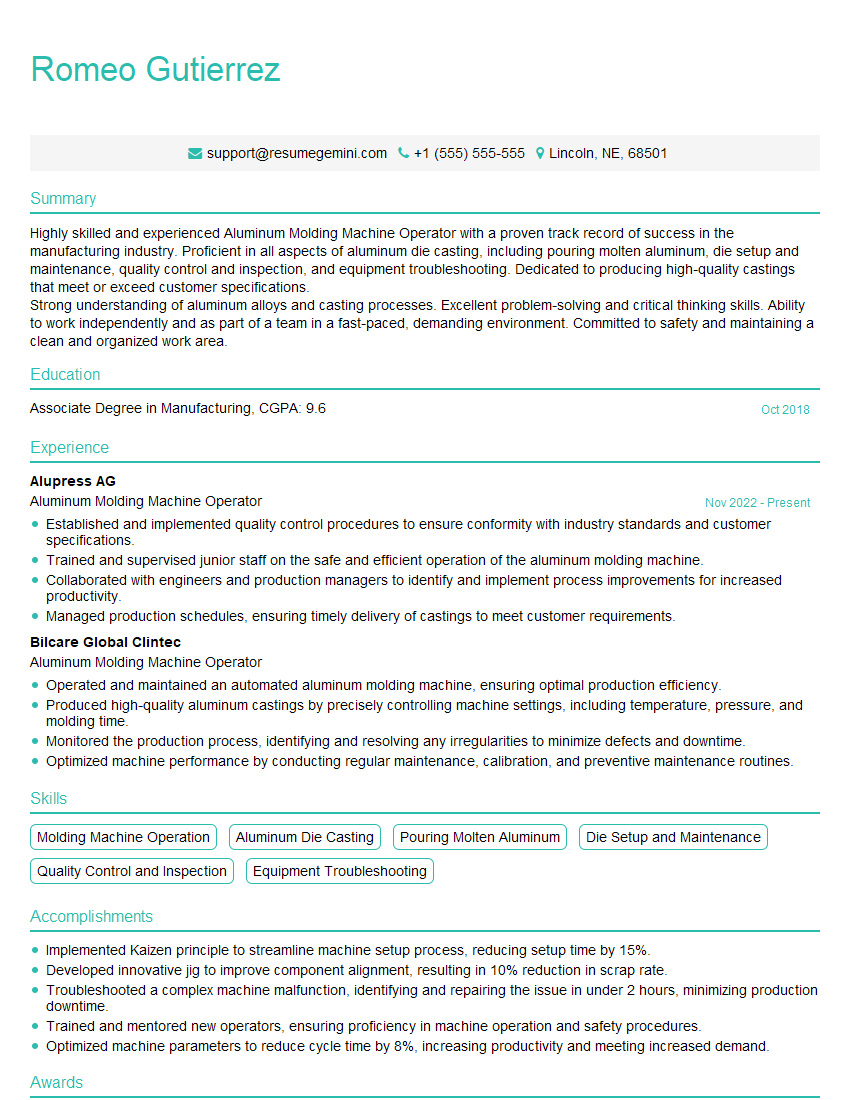

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aluminum Molding Machine Operator

1. What is the extrusion process of Aluminum Molding Machine?

The extrusion process of Aluminum Molding Machine involves several steps:

- Melting and Alloying: The aluminum is first melted and alloyed to achieve the desired composition and properties.

- Homogenization: The molten aluminum is homogenized to ensure uniform composition and grain structure.

- Billet Casting: The molten aluminum is cast into billets, which are cylindrical or rectangular blocks.

- Extrusion: The billet is heated and then forced through a die opening, which shapes the aluminum into the desired profile.

- Cooling and Aging: The extruded aluminum is cooled rapidly to maintain its shape and then aged to enhance its strength and hardness.

2. How do you maintain the aluminum molding machine?

Preventive Maintenance

- Regularly lubricate all moving parts.

- Inspect the die and mold for wear and tear.

- Clean the machine and work area to remove any aluminum shavings or debris.

Corrective Maintenance

- Troubleshoot and repair any malfunctions or breakdowns.

- Replace worn or damaged parts.

- Perform major overhauls as needed.

3. What are the different types of molds used in aluminum molding?

- Permanent molds: These molds are made of metal and are used for high-volume production.

- Semi-permanent molds: These molds have metal inserts that are combined with sand or other materials.

- Sand molds: These molds are made entirely of sand and are used for low-volume production.

- Investment casting molds: These molds are made of ceramic and are used for producing complex shapes.

4. What safety precautions should be taken when operating an aluminum molding machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Follow all operating procedures and safety protocols.

- Be aware of potential hazards, such as hot surfaces, moving parts, and sharp edges.

- Never operate the machine under the influence of alcohol or drugs.

- Report any unsafe conditions or malfunctions to your supervisor immediately.

5. What are the common defects in aluminum molding and how can they be prevented?

- Cold shuts: These defects occur when the molten aluminum does not completely fill the mold cavity.

- Porosity: These defects are caused by trapped air or gas bubbles in the molten aluminum.

- Slag inclusions: These defects are caused by foreign materials that contaminate the molten aluminum.

- Warpage: This defect occurs when the extruded aluminum profile deforms after cooling.

- Proper mold design and maintenance

- Correct operating temperature and pressure

- Adequate degassing of the molten aluminum

- Proper cooling and aging processes

6. How do you ensure the quality of the aluminum molding process?

- Process control: Monitoring and controlling process parameters such as temperature, pressure, and flow rate.

- Quality inspection: Regularly inspecting the extruded aluminum profiles for defects and dimensional accuracy.

- Non-destructive testing: Using ultrasonic or X-ray testing to detect internal defects.

- Statistical process control: Analyzing data to identify and reduce process variability.

7. What are some of the challenges in operating an aluminum molding machine?

- High temperatures: The molten aluminum and the extrusion process generate high temperatures, which require proper ventilation and cooling systems.

- Heavy loads: The billets and extruded aluminum profiles can be heavy, requiring proper lifting equipment and handling techniques.

- Machine downtime: Malfunctions or breakdowns can cause unplanned downtime, leading to production delays.

- Safety hazards: The operation of the machine involves potential hazards such as hot surfaces, moving parts, and sharp edges.

8. What types of maintenance are performed on an aluminum molding machine?

- Preventive maintenance: Regularly scheduled inspections, lubrication, and cleaning to prevent malfunctions.

- Predictive maintenance: Monitoring machine parameters and conducting vibration analysis to identify potential issues before they occur.

- Corrective maintenance: Repairing or replacing faulty components to restore machine functionality.

- Overhauls: Major maintenance tasks performed periodically to ensure the long-term reliability and performance of the machine.

9. How do you troubleshoot common problems with an aluminum molding machine?

Troubleshooting common problems involves the following steps:

- Identify the problem: Observe the symptoms and gather information about the machine’s operation.

- Check for loose connections: Ensure all electrical and mechanical connections are tight.

- Inspect for damaged components: Look for broken parts, worn bearings, or leaks.

- Consult the manufacturer’s manual: Refer to the manual for specific troubleshooting procedures and diagnostic codes.

- Contact the manufacturer or a qualified technician: If the problem cannot be resolved, seek professional assistance.

10. How do you stay up-to-date on the latest technologies and best practices in aluminum molding?

- Attend industry conferences and workshops: Network with experts and learn about new technologies and advancements.

- Read trade publications and technical journals: Stay informed about the latest research and industry trends.

- Participate in online forums and discussion groups: Engage with others in the field to share knowledge and troubleshoot issues.

- Attend training provided by the machine manufacturer: Gain hands-on experience with new equipment and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aluminum Molding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aluminum Molding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

To be successful as an Aluminum Molding Machine Operator, you will assume an array of duties as follows:

1. Monitor Production

Constantly observes and monitors production operations to ensure the smooth and efficient functioning of the molding machines.

- Maintains a vigilant watch on the production process, checking for any irregularities or deviations from standard operating procedures.

- Quickly identifies and addresses any issues that arise, taking prompt corrective action to minimize downtime and maintain productivity.

2. Operate Machinery

Skillfully operates and controls aluminum molding machines, ensuring their proper functioning and adherence to production specifications.

- Meticulously follows established operating procedures, adjusting machine settings and parameters as needed to achieve optimal molding results.

- Monitors and maintains the machines’ performance, conducting regular inspections and preventive maintenance to prevent breakdowns and ensure longevity.

3. Inspect Products

Thoroughly inspects the molded aluminum products to verify their quality, accuracy, and conformity to specifications.

- Utilizes specialized measuring tools and inspection techniques to assess product dimensions, surface finish, and other critical attributes.

- Identifies any defective or non-conforming products, promptly segregating them for further evaluation or corrective action.

4. Maintain Work Area

Maintains a clean, organized, and safe work area, adhering to established safety protocols and industry best practices.

- Regularly cleans and lubricates machines, tools, and equipment to prevent corrosion, wear, and malfunction.

- Proactively identifies potential hazards and takes appropriate measures to eliminate or minimize risks, ensuring a safe and healthy work environment.

Interview Tips

To assist you in making a strong impression during your interview, consider implementing these effective tips:

1. Research the Company and Position

Demonstrate your genuine interest and enthusiasm for the role by thoroughly researching the company and the specific position you are applying for.

- Visit the company’s website to gather information about their products, services, and company culture.

- Review the job description thoroughly, identifying the key responsibilities, skills, and qualifications required for the position.

2. Practice Answering Common Interview Questions

Prepare for the interview by practicing your responses to common interview questions, particularly those related to your experience and qualifications.

- Anticipate questions about your technical skills, ability to operate aluminum molding machines, and experience in inspecting and maintaining products.

- Craft concise and articulate answers that highlight your strengths and demonstrate your alignment with the job requirements.

3. Emphasize Your Safety Awareness

Given the potential hazards associated with operating heavy machinery, emphasize your strong safety awareness and commitment to maintaining a safe work environment.

- Highlight your knowledge of safety protocols and industry best practices, as well as your experience in identifying and mitigating potential risks.

- Convey your willingness to participate in safety training and drills to ensure your own safety and that of your colleagues.

4. Showcase Your Problem-Solving Abilities

As an Aluminum Molding Machine Operator, you will likely encounter unexpected challenges and issues during production.

- Provide examples from your previous experience where you successfully identified and resolved machine malfunctions or product defects.

- Emphasize your analytical thinking skills, ability to troubleshoot problems, and take decisive action to minimize downtime and maintain productivity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aluminum Molding Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.