Feeling lost in a sea of interview questions? Landed that dream interview for Aluminum Polisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Aluminum Polisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

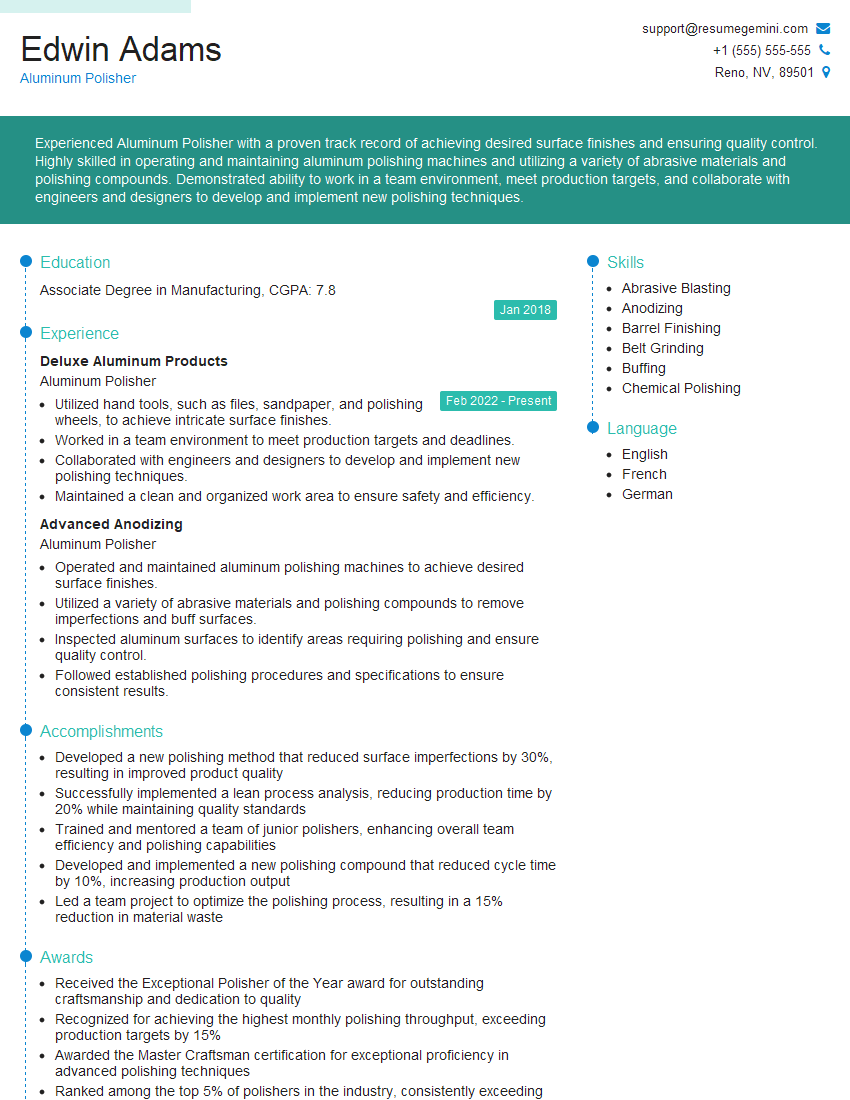

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aluminum Polisher

1. Describe the steps involved in the aluminum polishing process.

The aluminum polishing process typically involves the following steps:

- Cleaning the aluminum surface to remove any dirt, debris, or contaminants.

- Sanding the aluminum surface to create a smooth and even surface.

- Applying a polishing compound to the aluminum surface and using a polishing wheel or machine to polish the surface.

- Buffing the aluminum surface to remove any remaining polishing compound and to achieve a high shine.

2. What types of polishing wheels and compounds are used for aluminum polishing?

Polishing wheels

- Cotton wheels: Used for general-purpose polishing.

- Sisal wheels: Used for heavy-duty polishing.

- Felt wheels: Used for fine polishing and buffing.

Polishing compounds

- Aluminum oxide: Used for heavy-duty polishing.

- Chromium oxide: Used for fine polishing and buffing.

- Tripoli compound: Used for general-purpose polishing.

3. How do you determine the correct grit of sandpaper to use for aluminum polishing?

The grit of sandpaper to use for aluminum polishing depends on the condition of the aluminum surface and the desired finish. Generally, a coarser grit sandpaper will be used for removing scratches or other imperfections, while a finer grit sandpaper will be used for achieving a high shine.

4. What safety precautions should be taken when aluminum polishing?

When aluminum polishing, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and a respirator.

- Operate polishing equipment in a well-ventilated area.

- Keep the polishing area clean and free of dust and debris.

- Be aware of the potential for fire hazards when using polishing compounds.

5. How do you troubleshoot common problems that occur during aluminum polishing?

Some common problems that occur during aluminum polishing include:

- Swirls or scratches: This can be caused by using a polishing wheel that is too coarse or by applying too much pressure.

- Haze or cloudiness: This can be caused by using a polishing compound that is too fine or by not buffing the surface properly.

- Black streaks: This can be caused by using a polishing compound that contains abrasives that are too harsh.

6. What are the different types of finishes that can be achieved with aluminum polishing?

The different types of finishes that can be achieved with aluminum polishing include:

- Brushed finish: This finish has a matte appearance and is created by using a brush or abrasive wheel to polish the surface.

- Satin finish: This finish has a slightly shiny appearance and is created by using a fine-grit sandpaper or polishing wheel to polish the surface.

- Mirror finish: This finish has a highly reflective appearance and is created by using a very fine-grit sandpaper or polishing wheel to polish the surface.

7. How do you maintain aluminum polished surfaces?

To maintain aluminum polished surfaces, it is important to:

- Clean the surface regularly with a mild detergent and water.

- Apply a protective coating, such as a wax or sealant, to the surface.

- Avoid using harsh cleaners or abrasives on the surface.

8. What are the advantages of using aluminum polishing?

The advantages of using aluminum polishing include:

- Improved appearance

- Increased durability

- Corrosion resistance

- Increased reflectivity

9. What are the challenges of aluminum polishing?

Some of the challenges of aluminum polishing include:

- The process can be time-consuming.

- It requires specialized equipment and materials.

- It can be difficult to achieve a consistent finish.

10. How do you stay up-to-date on the latest advances in aluminum polishing techniques?

I stay up-to-date on the latest advances in aluminum polishing techniques by:

- Reading trade publications

- Attending industry conferences and workshops

- Networking with other professionals in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aluminum Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aluminum Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aluminum Polishers are responsible for performing a variety of tasks related to the polishing of aluminum products. Key job responsibilities of an Aluminum Polisher include:

1. Preparation of Aluminum Surfaces

Polishing aluminum may include several steps, which start with surface preparation. Aluminum Polishers ensure that the aluminum surface is clean and free of any contaminants, such as dirt, oil, or grease. Contaminants can hinder the polishing process and affect the final finish.

- Clean and degrease aluminum surfaces

- Remove oxidation and other surface imperfections

2. Selection of Polishing Tools and Equipment

Aluminum Polishers select the appropriate polishing tools and equipment based on the type of aluminum product and the desired finish. They may use a variety of tools, such as buffing wheels, polishing compounds, and abrasives.

- Select and use appropriate polishing tools and equipment

- Maintain and calibrate polishing equipment

3. Polishing Techniques

Aluminum Polishers apply different polishing techniques to achieve the desired finish. They may use a variety of polishing techniques, such as hand polishing, machine polishing, and buffing. The specific techniques used will depend on the type of aluminum product and the desired finish.

- Polish aluminum surfaces to achieve a desired finish

- Monitor and adjust polishing parameters to ensure quality standards

4. Quality Control and Inspection

Aluminum Polishers inspect the finished products to ensure that they meet quality standards. They may use a variety of inspection techniques, such as visual inspection and dimensional measurement. They also document the results of their inspections.

- Inspect and ensure the quality of polished aluminum products

- Identify and correct defects in the polishing process

Interview Tips

To ace an interview for an Aluminum Polisher position, it is important to prepare and practice in advance. Here are some tips to help you prepare for the interview:

1. Research the Company and the Position

Learn more about the company and the Aluminum Polisher position before the interview. This will help you understand the company’s culture, values, and expectations for the role. You can research the company’s website, social media pages, and industry news.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies in aluminum polishing.

2. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Aluminum Polisher position. Focus on your ability to prepare aluminum surfaces, select and use polishing tools and equipment, and apply polishing techniques. You can also mention your experience with quality control and inspection.

- Quantify your accomplishments whenever possible. For example, instead of saying “I polished aluminum products,” you could say “I polished over 10,000 aluminum products, resulting in a 99% customer satisfaction rate.”

- Be prepared to answer questions about your experience with specific polishing techniques and equipment.

3. Prepare for Common Interview Questions

There are some common interview questions that you may be asked during an interview for an Aluminum Polisher position. Some of the most common questions include:

- Tell me about your experience with aluminum polishing.

- What are the different types of polishing techniques that you are familiar with?

- What are the most important factors to consider when selecting polishing tools and equipment?

- How do you ensure the quality of your work?

4. Practice Your Answers

Once you have prepared your answers to common interview questions, it is important to practice your delivery. Practice answering questions out loud, and ask a friend or family member to give you feedback. This will help you become more confident and articulate during the interview.

- Time yourself to make sure that your answers are concise and to the point.

- Ask a friend or family member to give you feedback on your answers.

Next Step:

Now that you’re armed with the knowledge of Aluminum Polisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Aluminum Polisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini