Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Aluminum Siding Applicator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Aluminum Siding Applicator so you can tailor your answers to impress potential employers.

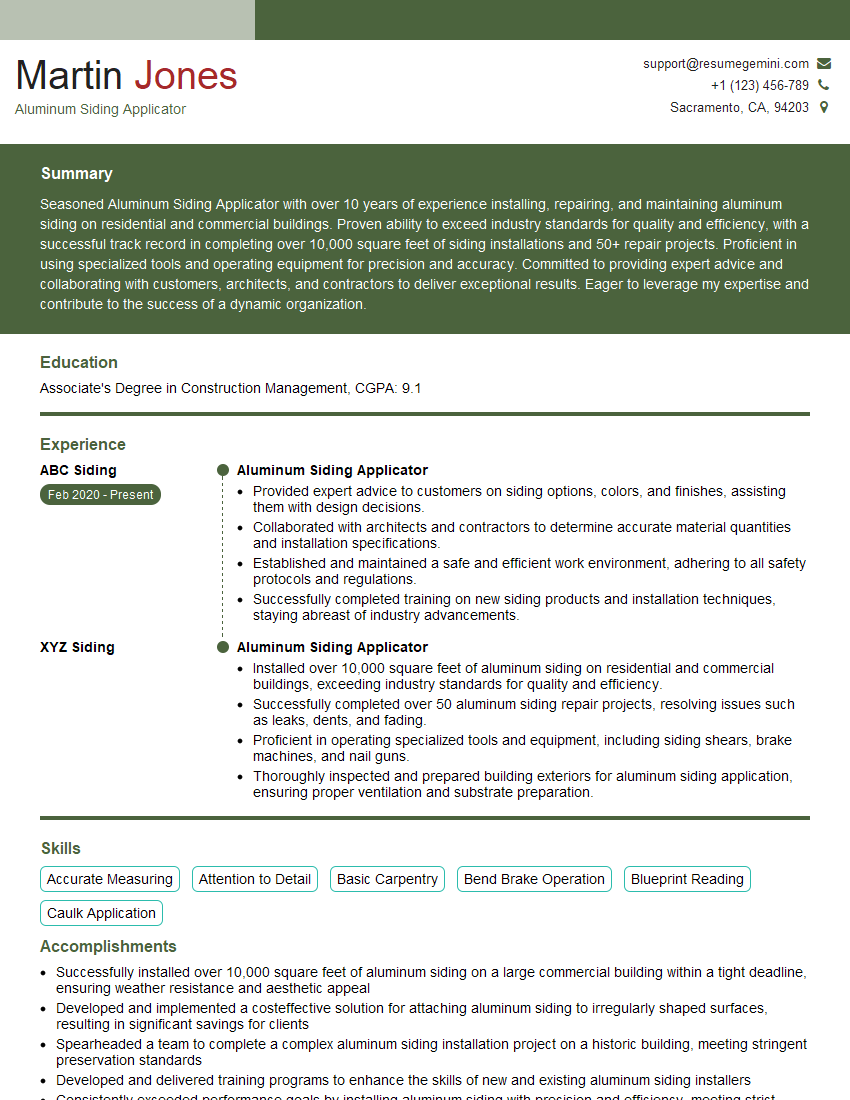

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aluminum Siding Applicator

1. Describe the process of installing aluminum siding on a house?

The process of installing aluminum siding on a house typically involves several steps:

- Preparing the house: This includes removing any existing siding, inspecting the exterior walls, and making any necessary repairs.

- Installing the starter strip: The starter strip is a metal strip that is attached to the bottom of the house and provides a base for the siding.

- Installing the corner posts: The corner posts are vertical strips that are installed at the corners of the house and provide support for the siding.

- Installing the J-channels: The J-channels are metal strips that are installed around windows and doors and provide a finished look.

- Installing the siding panels: The siding panels are the main component of the aluminum siding and are installed one by one, starting from the bottom and working upwards.

- Trimming and finishing: Once all of the siding panels are installed, the edges are trimmed and any necessary finishing touches are applied, such as caulk or sealant.

2. What are the different types of aluminum siding available?

There are several different types of aluminum siding available, including:

Horizontal siding:

- Lap siding: This is the most common type of aluminum siding and consists of horizontal panels that overlap each other.

- Board and batten siding: This type of siding consists of wide planks that are installed vertically and are overlapped by narrower battens.

- Channel siding: This type of siding consists of narrow panels that are installed horizontally and have a ribbed or grooved surface.

Vertical siding:

- V-groove siding: This type of siding consists of panels that have a V-shaped groove running down the center.

- Tongue and groove siding: This type of siding consists of panels that have a tongue and groove joint that interlocks.

- Shiplap siding: This type of siding consists of panels that are overlapped and have a slight rabbet on one edge.

3. What are the advantages and disadvantages of aluminum siding?

Advantages of aluminum siding:

- Durable and long-lasting

- Low maintenance

- Fire-resistant

- Pest-resistant

- Versatile and available in a variety of colors and styles

Disadvantages of aluminum siding:

- Can be dented or damaged by hail or other impacts

- Can be expensive to install

- May not be as insulating as other types of siding

4. What are some of the common problems that can occur with aluminum siding?

Some of the common problems that can occur with aluminum siding include:

- Fading or chalking: This can occur due to exposure to the sun and weather.

- Denting or damage: This can occur due to hail, wind, or other impacts.

- Corrosion: This can occur due to exposure to moisture or salt.

- Buckling or warping: This can occur due to temperature changes or improper installation.

5. What are some tips for maintaining aluminum siding?

Here are some tips for maintaining aluminum siding:

- Clean the siding regularly: Use a mild soap and water solution and a soft cloth or sponge to clean the siding.

- Inspect the siding for damage: Regularly inspect the siding for any signs of damage, such as dents, cracks, or corrosion.

- Repair any damage promptly: If you find any damage, repair it promptly to prevent it from becoming worse.

- Repaint the siding as needed: If the siding starts to fade or chalk, you may need to repaint it to restore its appearance.

6. What are some of the safety precautions that should be taken when installing aluminum siding?

When installing aluminum siding, it is important to take the following safety precautions:

- Wear appropriate safety gear: This includes safety glasses, gloves, and a hard hat.

- Use a ladder safely: When working on a ladder, always make sure that it is properly positioned and secure.

- Avoid electrical hazards: Be aware of any electrical wires or outlets when working on the siding.

- Be careful when using power tools: Always follow the manufacturer’s instructions when using power tools and wear appropriate safety gear.

- Work with a partner: If possible, work with a partner when installing aluminum siding for safety reasons.

7. What are the different tools and materials that are needed to install aluminum siding?

The following tools and materials are typically needed to install aluminum siding:

- Aluminum siding panels

- Starter strip

- Corner posts

- J-channels

- Caulk and sealant

- Tin snips

- J-channel cutter

- Hammer or nail gun

- Ladder

- Safety glasses, gloves, and hard hat

8. How do you determine the amount of siding that is needed for a project?

To determine the amount of siding that is needed for a project, you need to measure the area that you will be covering and calculate the square footage.

- Measure the length and width of the area: Multiply the length by the width to get the square footage.

- Add 10% for waste: This will account for any cuts or mistakes that you make.

- Divide the square footage by the coverage area of the siding: The coverage area of the siding will be specified by the manufacturer.

- Round up to the nearest whole number: This will give you the number of siding panels that you need.

9. What is the best way to cut aluminum siding?

The best way to cut aluminum siding is to use tin snips. Tin snips are a type of scissors that are specifically designed for cutting thin metal.

- Score the siding: Use a utility knife or a scoring tool to score the siding along the line that you want to cut.

- Cut the siding: Use tin snips to cut the siding along the score line.

- Deburr the edges: Use a file or a deburring tool to remove any sharp edges from the cut.

10. How do you install aluminum siding around windows and doors?

To install aluminum siding around windows and doors, you will need to use J-channels.

- Install the J-channels: Install the J-channels around the windows and doors using screws or nails.

- Cut the siding: Cut the siding to fit around the windows and doors.

- Insert the siding into the J-channels: Insert the siding into the J-channels and secure it with screws or nails.

- Caulk the edges: Caulk the edges of the siding around the windows and doors to prevent water from getting in.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aluminum Siding Applicator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aluminum Siding Applicator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aluminum Siding Applicators are responsible for the installation and repair of aluminum siding on various types of structures. They work closely with homeowners, contractors, and architects to ensure that the project is completed according to specifications and meets the needs of the customer.

1. Preparation

Preparing the work area by removing old siding, trimming, and gutters.

- Inspecting the structure to determine the condition of the existing siding and any necessary repairs.

- Measuring and marking the location of the new siding.

2. Installation

Installing aluminum siding panels and trims using nails, screws, or other fasteners.

- Cutting and fitting the siding panels to size.

- Applying sealant around the edges of the siding panels to prevent water infiltration.

3. Finishing

Trimming and finishing the siding with corner pieces, fascia, and soffit.

- Installing gutters and downspouts to direct rainwater away from the home.

- Cleaning up the work area and removing any debris.

4. Maintenance and Repair

Inspecting and repairing existing aluminum siding to maintain its appearance and functionality.

- Replacing damaged or missing siding panels.

- Re-caulking around the edges of the siding to prevent water infiltration.

Interview Tips

Preparing for an interview for an Aluminum Siding Applicator position requires research, practice, and confidence. Here are some tips to help you ace your interview:

1. Research the Company and Role

Thoroughly research the company you’re applying to, their values, and their product or service. This will help you understand their business and demonstrate your interest in the position.

- Visit the company website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful and concise answers. Practice delivering your answers aloud to improve your fluency and confidence.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your accomplishments whenever possible to provide evidence of your impact.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Focus on transferable skills that are applicable to the Aluminum Siding Applicator role.

- Demonstrate your attention to detail and precision in previous roles.

- Highlight your ability to work independently and as part of a team.

4. Ask Thoughtful Questions

Prepare a few thoughtful questions to ask the interviewer at the end of the interview. This shows your engagement and interest in the company and the role.

- Ask about the company’s growth plans or industry outlook.

- Inquire about opportunities for professional development and training.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. Maintain eye contact, speak clearly, and demonstrate a positive and enthusiastic attitude.

- Choose attire that is appropriate for the industry and company culture.

- Be punctual and allow ample time for unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aluminum Siding Applicator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.