Are you gearing up for an interview for a Aluminum Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Aluminum Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

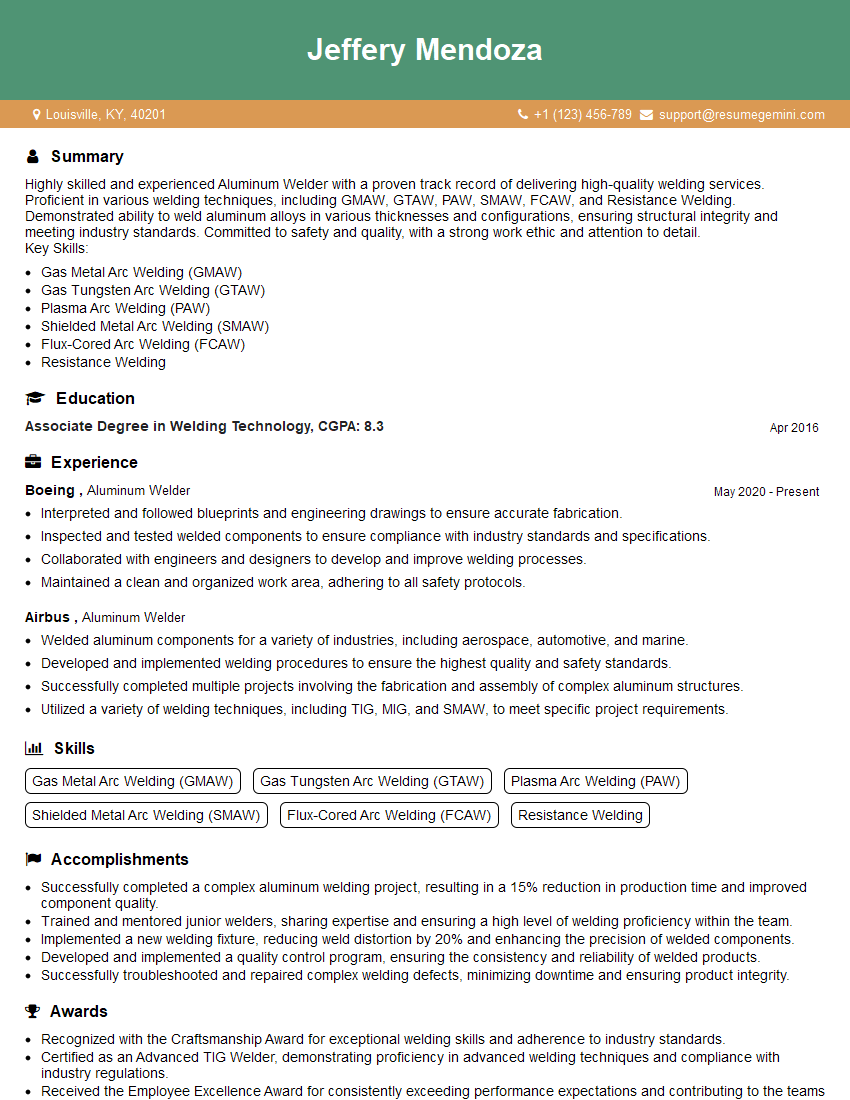

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aluminum Welder

1. What are the different welding processes used for Aluminum?

- Gas Tungsten Arc Welding (GTAW)

- Gas Metal Arc Welding (GMAW)

- Pulsed Metal Arc Welding (P-MIG)

- Resistance Spot Welding (RSW)

- Friction Stir Welding (FSW)

2. Describe the pre-weld preparation required for Aluminum Welding?

Surface Cleaning

- Remove dirt, grease, and oxides

- Use acetone or methyl ethyl ketone (MEK)

Joint Preparation

- Chamfering or beveling edges to ensure weld penetration

- Cleaning the joint with a wire brush or grinding tool

3. What are the common welding defects in Aluminum Welding and how to prevent them?

- Porosity: Caused by entrapped gas. Prevent by proper shielding gas, dry filler material, and joint preparation.

- Cracking: Caused by excessive heat input or restraint. Prevent by proper welding parameters, joint design, and post-weld heat treatment.

- Inclusions: Foreign material in the weld. Prevent by proper joint preparation, clean filler material, and shielding gas.

4. How do you determine the correct welding parameters for Aluminum Welding?

- Consider material thickness

- Select the appropriate welding process

- Consult welding procedure specifications (WPS)

- Adjust amperage, voltage, and travel speed based on experience and trial welds

5. What is the importance of shielding gas in Aluminum Welding?

- Protects the weld pool from oxidation

- Provides a stable arc

- Influences the bead shape and penetration

6. How do you control the heat input while welding Aluminum?

- Adjust amperage and voltage

- Use the appropriate shielding gas

- Maintain a steady travel speed

- Allow for cooling time between passes

7. What are the different Aluminum alloys used in welding?

- 1xxx: Pure Aluminum

- 3xxx: Manganese Alloy

- 5xxx: Magnesium Alloy

- 6xxx: Magnesium and Silicon Alloy

- 7xxx: Zinc Alloy

8. How do you inspect Aluminum welds?

- Visual inspection

- Non-destructive testing (NDT) methods

- Radiographic Testing (RT)

- Ultrasonic Testing (UT)

9. What are the safety precautions to be taken while welding Aluminum?

- Wear appropriate PPE (gloves, mask, apron)

- Ensure adequate ventilation

- Use fire-resistant materials

- Avoid direct exposure to UV radiation

10. Describe a challenging Aluminum welding project you have worked on.

- Briefly describe the project and its requirements.

- Explain the welding techniques and processes used.

- Highlight any challenges encountered and how they were overcome.

- State the final outcome and any quality control measures implemented.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aluminum Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aluminum Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Aluminum Welder is responsible for joining aluminum components using specialized welding techniques. The following are the key job responsibilities:

1. Welding and Fabrication

Using various welding equipment and techniques, aluminum welders join aluminum components to create or repair structures and parts. They must ensure that welds meet the required specifications and quality standards.

- Use welding equipment, including MIG, TIG, and oxy-fuel torches.

- Follow welding procedures and blueprints to fabricate and repair aluminum parts.

- Inspect welds to ensure they meet quality standards and specifications.

2. Material Preparation

Before welding, aluminum welders prepare the aluminum surfaces by cleaning, grinding, and fitting them together. Proper preparation ensures strong and durable welds.

- Clean and prepare aluminum surfaces for welding.

- Cut and fit aluminum components using hand or power tools.

- Assemble and position aluminum parts for welding.

3. Safety and Maintenance

Aluminum welders prioritize safety by wearing appropriate protective gear and following safety protocols. They also perform regular maintenance on welding equipment to ensure optimal performance.

- Wear appropriate protective gear, such as helmets, gloves, and respirators.

- Follow safety protocols and procedures to prevent accidents and injuries.

- Maintain welding equipment, including cleaning and calibrating.

4. Quality Control

Aluminum welders are responsible for ensuring the quality of their welds. They conduct inspections and tests to verify that welds meet the required specifications and standards.

- Inspect welds using visual, non-destructive testing methods.

- Perform quality control tests, such as tensile and bend tests.

- Maintain records of welding activities and quality control results.

Interview Tips

To ace an interview for an Aluminum Welder position, candidates should prepare thoroughly and highlight their skills and experience. Here are some interview tips:

1. Research the Company and Position

Before the interview, research the company and the specific Aluminum Welder position. Understanding the company’s values, industry, and job requirements will enable you to tailor your answers and demonstrate your interest.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Review the job description carefully.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. This will help you feel more confident and articulate during the interview. Consider questions related to your welding skills, experience, and safety practices.

- Describe your experience with different welding techniques.

- Provide examples of projects where you demonstrated your welding abilities.

- Discuss your knowledge of safety protocols and industry standards.

3. Showcase Your Passion for Welding

Highlight your passion for welding and why you are interested in the position. Explain how your skills and experience align with the company’s needs. Enthusiasm and dedication can make a positive impression on interviewers.

- Describe what drew you to aluminum welding.

- Share your experience with personal welding projects or hobbies.

- Explain why you are interested in working for the specific company.

4. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows that you are engaged and interested in the position. Prepare questions about the company’s projects, growth opportunities, or the specific role.

- Inquire about the company’s current or upcoming welding projects.

- Ask about the company’s commitment to training and professional development.

- Request clarification on the role’s responsibilities and expectations.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Aluminum Welder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Aluminum Welder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.