Feeling lost in a sea of interview questions? Landed that dream interview for Ammonia Box Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ammonia Box Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

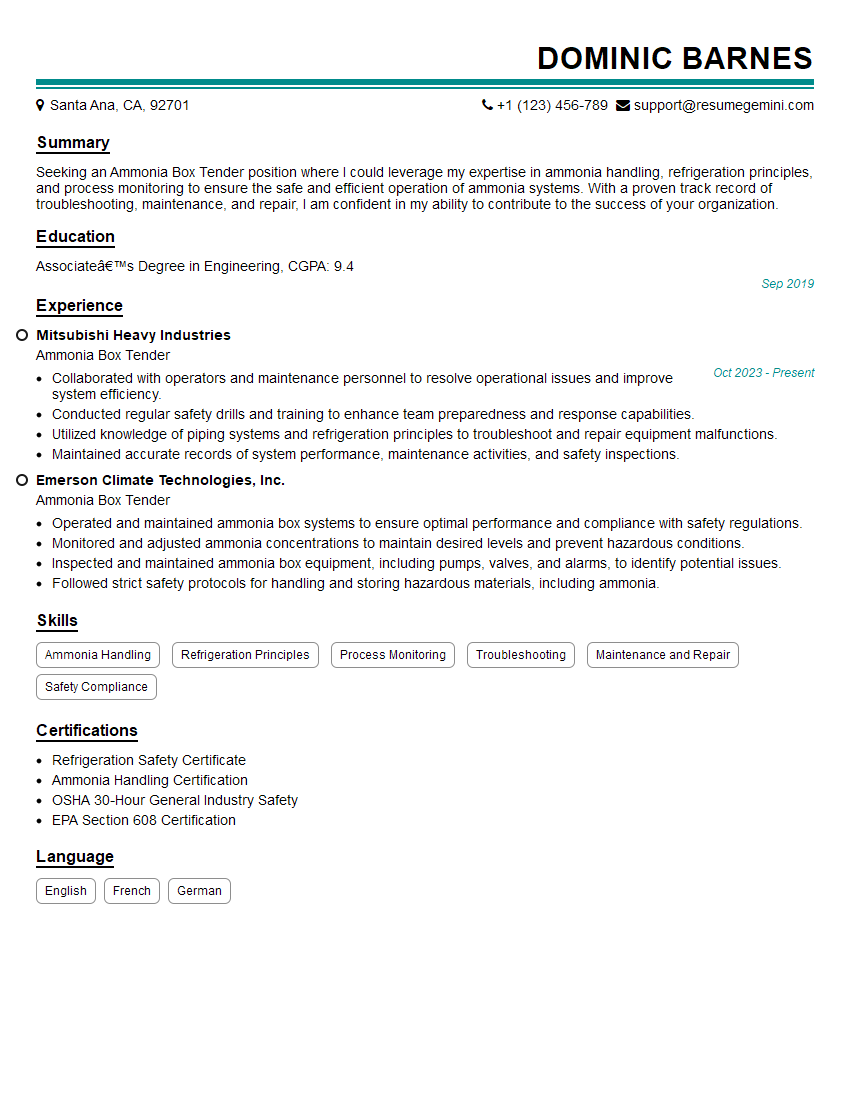

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammonia Box Tender

1. Explain the key responsibilities of an Ammonia Box Tender?

As an Ammonia Box Tender, my primary responsibilities would include:

- Monitoring and maintaining the ammonia system to ensure optimal operation.

- Conducting regular inspections of the system, including pumps, valves, and tanks, to identify and address potential issues.

- Performing routine maintenance tasks, such as changing filters, cleaning equipment, and lubricating moving parts.

- Troubleshooting and resolving any system failures or malfunctions.

- Adhering to all safety protocols and regulations related to handling ammonia.

2. Describe the different types of ammonia systems and their applications?

There are various types of ammonia systems, each designed for specific applications. Some common types include:

Refrigeration Systems:

- Used in industrial and commercial refrigeration applications.

- Ammonia is used as the refrigerant due to its high efficiency and low cost.

Absorption Systems:

- Employed in cooling applications where there is a high demand for heat.

- Ammonia absorbs heat from a source and releases it to a cooling medium.

Power Generation Systems:

- Used in power plants to remove impurities from gases.

- Ammonia is used as a scrubbing agent to capture pollutants.

3. How do you ensure the safety of the ammonia system and mitigate potential risks?

Ensuring the safety of the ammonia system is paramount. Here are some key measures I would implement:

- Regularly inspect and test all system components to identify and address any leaks or faults.

- Wear appropriate personal protective equipment (PPE) when handling ammonia, including gloves, respirators, and protective clothing.

- Establish clear emergency response procedures and ensure all personnel are trained on them.

- Coordinate with relevant authorities and emergency services to ensure a prompt response in case of an incident.

- Maintain detailed records of all maintenance and inspection activities for traceability and compliance.

4. Explain the importance of maintaining optimal ammonia levels in the system?

Maintaining optimal ammonia levels is crucial for the efficient operation of the system. Here’s why:

- Cooling Performance: Ammonia levels directly impact the cooling capacity of the system. Optimal levels ensure maximum heat transfer and cooling efficiency.

- System Corrosion: High ammonia concentrations can lead to corrosion of system components, while low levels can result in reduced cooling performance.

- Safety: Maintaining optimal levels minimizes the risk of ammonia leaks, which can pose safety hazards to personnel and the environment.

5. How do you handle situations where the ammonia system malfunctions or breaks down?

In the event of a system malfunction or breakdown, I would take the following steps:

- Safety First: Prioritize the safety of personnel and the environment. Evacuate the area if necessary and alert appropriate authorities.

- Identify the Issue: Conduct a thorough inspection of the system to identify the root cause of the malfunction.

- Repair or Replace: Repair or replace any faulty components or equipment promptly to restore system operation.

- Document and Review: Document the incident and review the system’s performance to identify potential areas for improvement and preventive maintenance.

6. Describe your experience in troubleshooting and resolving ammonia system issues?

Throughout my career, I have encountered various ammonia system issues and have successfully resolved them. Some examples include:

- Diagnosed and repaired ammonia leaks in piping and equipment.

- Troubleshooted and resolved issues related to pump failures and valve malfunctions.

- Performed maintenance and repairs on ammonia condensers and evaporators to optimize cooling performance.

7. How do you stay up-to-date with the latest industry standards and regulations related to ammonia handling?

Staying up-to-date with industry standards and regulations is essential. I utilize the following methods:

- Attend industry conferences and workshops: Participating in industry events provides opportunities to learn about new technologies, best practices, and regulatory updates.

- Read technical journals and publications: Subscribing to industry publications helps me stay informed about advancements and emerging issues.

- Consult with experts and manufacturers: Seeking advice from experienced professionals and equipment manufacturers ensures I have access to the latest information and recommendations.

8. What is your understanding of the Occupational Safety and Health Administration (OSHA) regulations for handling ammonia?

I am familiar with the OSHA regulations for handling ammonia, which include:

- Permissible Exposure Limits (PELs): OSHA establishes exposure limits for ammonia to protect workers from harmful levels.

- Engineering Controls: Employers are required to implement engineering controls, such as ventilation systems, to minimize worker exposure.

- Personal Protective Equipment (PPE): OSHA mandates the use of appropriate PPE, including respirators, gloves, and protective clothing, to safeguard workers.

9. How do you manage and coordinate with other team members in a fast-paced environment?

In a fast-paced environment, effective communication and coordination are crucial. I use the following strategies:

- Establish Clear Roles and Responsibilities: Defining specific roles and responsibilities for each team member ensures everyone understands their tasks and minimizes overlap.

- Regular Communication: Maintaining open and regular communication channels facilitates information sharing and timely decision-making.

- Utilizing Technology: Leveraging technology, such as project management software and instant messaging platforms, enhances collaboration and task tracking.

10. Why are you interested in this Ammonia Box Tender position, and what makes you a suitable candidate?

I am eager to join your organization as an Ammonia Box Tender because I am confident that my skills and experience align perfectly with the requirements of this role. With my in-depth knowledge of ammonia systems, proven troubleshooting abilities, and unwavering commitment to safety, I am positive that I can make a significant contribution to your team. Furthermore, my strong work ethic, attention to detail, and excellent communication skills make me a highly suitable candidate for this position.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammonia Box Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammonia Box Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ammonia Box Tenders are responsible for the safe and efficient operation of ammonia refrigeration systems, including the care and maintenance of ammonia boxes. They ensure that the ammonia system is operating within safe parameters, and take corrective action when necessary. Some of their key job responsibilities include:

1. Monitoring and maintaining ammonia refrigeration systems

Ammonia Box Tenders are responsible for monitoring the operation of ammonia refrigeration systems, including the ammonia box, compressor, condenser, and evaporator. They check for leaks, vibrations, and other abnormalities, and take corrective action as necessary. They also maintain records of system operation and maintenance.

2. Troubleshooting and repairing ammonia refrigeration systems

Ammonia Box Tenders troubleshoot and repair ammonia refrigeration systems when problems occur. They diagnose the problem, locate the source of the leak, and make repairs as necessary. They also replace worn or damaged parts.

3. Operating and maintaining ammonia pumps and compressors

Ammonia Box Tenders operate and maintain ammonia pumps and compressors. They start and stop the pumps and compressors, and adjust the speed and pressure as necessary. They also lubricate the pumps and compressors, and replace worn or damaged parts.

4. Handling and storing ammonia

Ammonia Box Tenders handle and store ammonia in a safe and responsible manner. They follow all safety procedures, and wear appropriate personal protective equipment (PPE). They also ensure that ammonia is stored in a cool, dry place, and that the containers are clearly labeled.

Interview Tips

Preparing for an interview can be a daunting task, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview for an Ammonia Box Tender position:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also help you prepare for questions about your qualifications and experience.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Practice answering these questions ahead of time so that you can deliver your answers confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills in ammonia refrigeration systems. Be prepared to talk about your knowledge of ammonia systems, your troubleshooting experience, and your ability to operate and maintain ammonia pumps and compressors.

4. Be prepared to answer questions about safety

Safety is a top priority for Ammonia Box Tenders. Be prepared to answer questions about your safety knowledge and experience. Describe your understanding of ammonia safety procedures, and discuss your experience with handling and storing ammonia.

5. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are eager to learn more about the company. It also gives you an opportunity to clarify any questions you have about the position or the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ammonia Box Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!