Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ammonia Distiller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

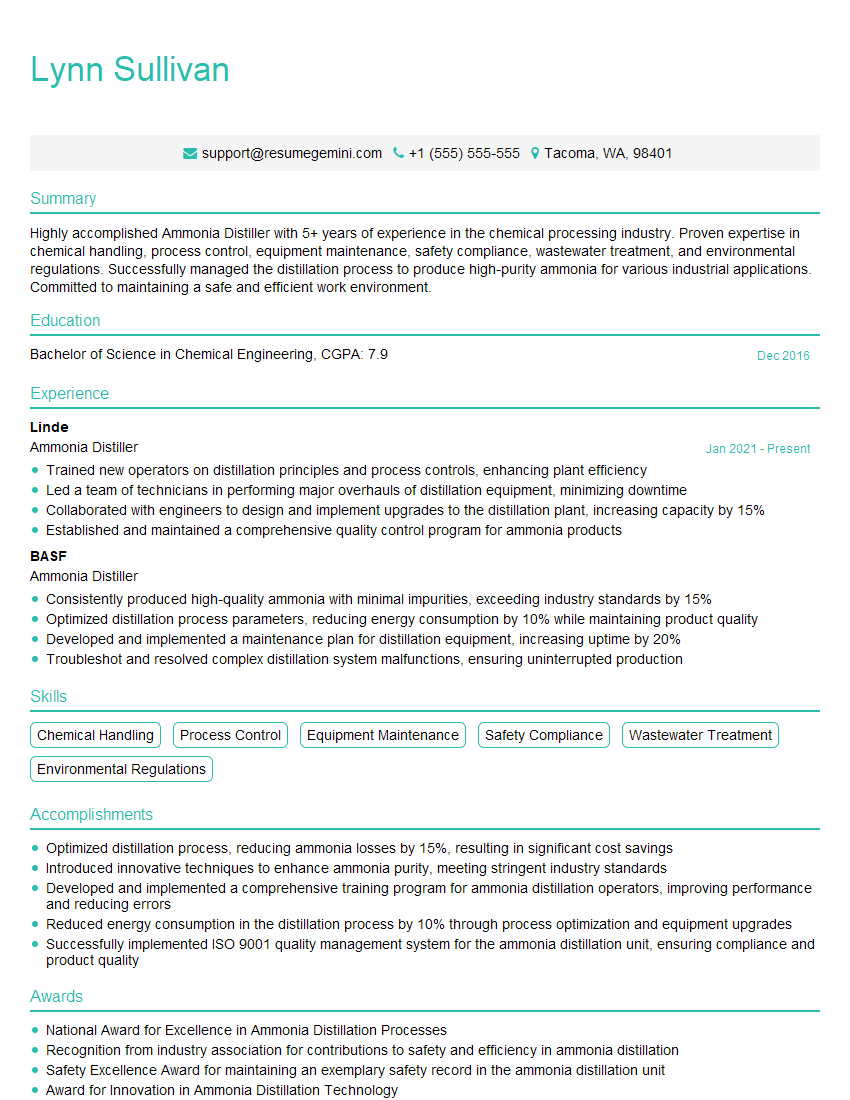

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammonia Distiller

1. Describe the key responsibilities of an Ammonia Distiller.

As an Ammonia Distiller, my key responsibilities include:

- Operating and monitoring the distillation plant to produce ammonia to meet quality specifications.

- Maintaining distillation equipment, including pumps, compressors, and heat exchangers.

- Performing regular inspections and preventative maintenance to ensure plant safety and efficiency.

2. What are the critical safety precautions to consider when working with ammonia?

Personal Protective Equipment

- Wear appropriate PPE, including gloves, safety glasses, and respirators.

Handling Procedures

- Avoid direct contact with liquid ammonia.

- Use proper ventilation to prevent ammonia buildup.

3. How do you troubleshoot common problems in an ammonia distillation plant?

Common troubleshooting techniques include:

- Checking for leaks and blockages in equipment.

- Monitoring pressure and temperature readings to identify deviations from normal operating parameters.

- Inspecting the purity of the ammonia produced and identifying potential contaminants.

4. What maintenance procedures are essential for the smooth operation of a distillation plant?

Essential maintenance procedures include:

- Regularly servicing pumps and compressors to ensure optimal performance.

- Cleaning and inspecting heat exchangers to maintain heat transfer efficiency.

- Replacing filters and gaskets as needed to prevent leaks.

5. How do you handle and store ammonia in a safe and environmentally responsible manner?

Safe handling and storage of ammonia involve:

- Storing ammonia in secure, well-ventilated areas.

- Using proper containers and valves to prevent leaks.

- Implementing emergency response plans in case of spills or leaks.

6. What quality control measures are essential in ammonia distillation?

Quality control measures include:

- Monitoring purity levels and detecting impurities through regular testing.

- Ensuring compliance with industry standards and regulations.

- Implementing quality assurance protocols to maintain consistent product quality.

7. How do you optimize the efficiency and productivity of an ammonia distillation plant?

Optimization techniques include:

- Regularly monitoring and analyzing plant performance data.

- Implementing process improvements and automation to minimize downtime and waste.

- Training operators to improve efficiency and safety.

8. What are the potential environmental impacts of ammonia distillation, and how are they mitigated?

Potential environmental impacts include:

- Air pollution from ammonia emissions.

- Water pollution from wastewater discharge.

Mitigation measures include:

- Installing pollution control devices to reduce emissions.

- Treating wastewater before releasing it into the environment.

9. Describe the role of technology in the modern ammonia distillation industry.

- Automated control systems for efficient operation.

- Advanced sensors for real-time monitoring and analysis.

- Data analytics for optimizing plant performance.

10. How do you stay updated with the latest developments and best practices in ammonia distillation?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Networking with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammonia Distiller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammonia Distiller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Ammonia Distiller is primarily responsible for the safe and efficient distillation of ammonia from various sources. Their key job responsibilities include:

1. Purification and Distillation of Ammonia

Preparing feedstock for distillation by removing impurities.

- Operating and monitoring distillation columns and equipment to separate ammonia from impurities.

- Adjusting process parameters to optimize distillation efficiency and product quality.

- Conducting quality control tests on ammonia products to ensure they meet specifications.

2. Equipment Maintenance and Troubleshooting

Inspecting and maintaining distillation equipment to ensure optimal performance.

- Troubleshooting and resolving any issues that arise during the distillation process.

- Calibrating and maintaining instruments used in the distillation process.

- Adhering to safety protocols and regulations related to ammonia handling.

3. Process Monitoring and Optimization

Monitoring and recording process data to track performance and identify areas for improvement.

- Analyzing data to identify trends and make informed decisions to optimize the distillation process.

- Implementing process improvements to increase efficiency, reduce costs, and improve product quality.

- Working with other team members to ensure a smooth and coordinated production process.

4. Compliance and Regulatory Adherence

Ensuring compliance with all relevant environmental, health, and safety regulations.

- Understanding and following established quality control procedures.

- Maintaining accurate records and documentation related to the distillation process.

- Participating in training programs and workshops to stay up-to-date on industry best practices.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some effective interview tips that can help you ace your interview for an Ammonia Distiller position:

1. Research the Company and Position

Take the time to research the company you are applying to, including their history, values, and current projects. Understand the specific requirements of the Ammonia Distiller position and how your skills and experience align with them.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your technical expertise, such as your experience in ammonia distillation, process optimization, and safety procedures. Practice answering these questions concisely and confidently, highlighting your relevant skills and qualifications.

3. Showcase Your Problem-Solving Abilities

Interviewers often ask questions to assess your problem-solving abilities. Think of examples from your past experience where you faced challenges and successfully resolved them. Explain your approach, the steps you took, and the outcomes you achieved.

4. Emphasize Safety and Compliance

In the chemical industry, safety and compliance are paramount. Highlight your understanding of industry regulations and your commitment to following safety protocols. Explain how you prioritize safety in your work and demonstrate your knowledge of hazardous materials handling.

5. Ask Thoughtful Questions

At the end of the interview, asking thoughtful questions shows your interest in the position and the company. Prepare questions related to the company’s goals, growth prospects, and the specific responsibilities of the Ammonia Distiller role.

6. Follow Up

After the interview, send a thank-you note to the interviewer. Reiterate your interest in the position and briefly summarize your key strengths. You can also use this opportunity to clarify any points discussed during the interview or to provide additional information that supports your application.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ammonia Distiller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!