Are you gearing up for a career in Ammonia Refrigeration Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ammonia Refrigeration Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

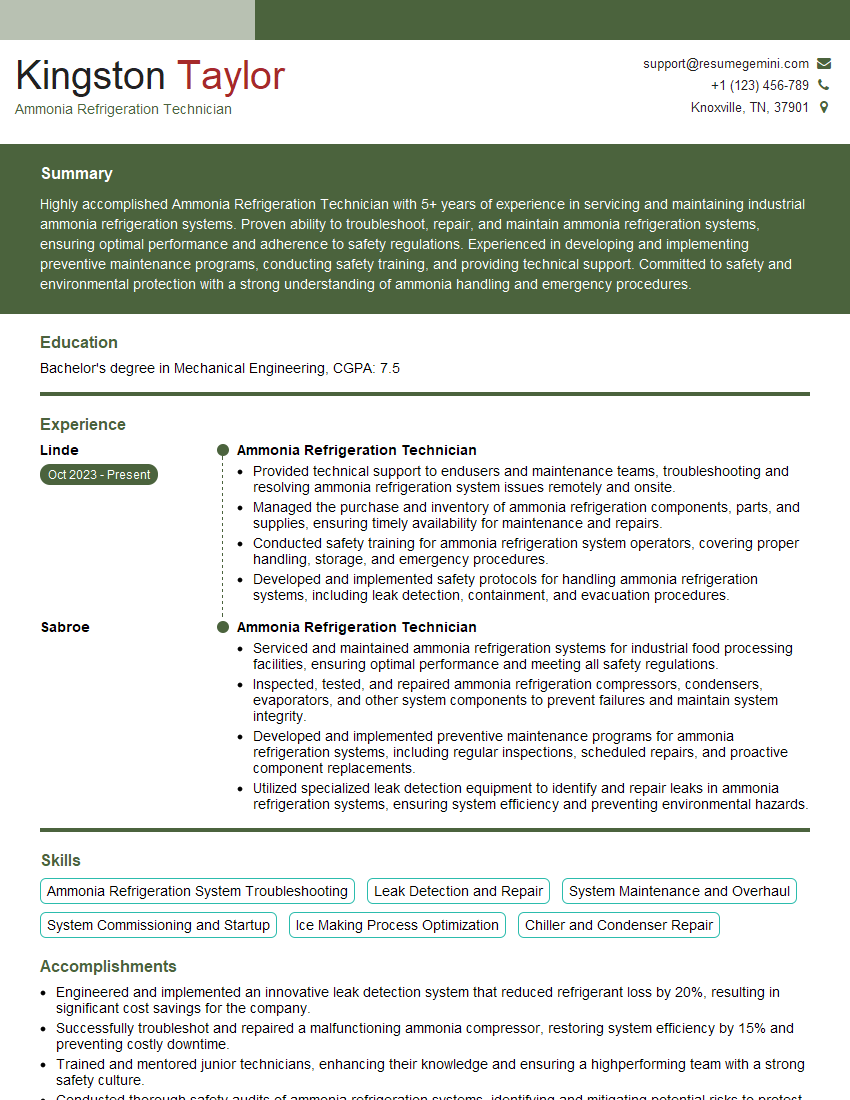

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammonia Refrigeration Technician

1. Describe the refrigeration cycle for an ammonia refrigeration system?

- In the evaporator, liquid ammonia absorbs heat from the refrigerated space, causing it to boil and become a vapor.

- The vaporized ammonia is compressed by the compressor, increasing its pressure and temperature.

- The high-pressure, high-temperature vapor flows through the condenser, where it releases heat to the surrounding environment and condenses back into a liquid.

- The liquid ammonia is then passed through an expansion valve, which reduces its pressure and temperature, and sends it back to the evaporator to repeat the cycle.

2. What are the safety precautions to be taken while working with ammonia refrigeration systems?

Chemical Hazards

- Ammonia is a toxic gas and can cause respiratory irritation, burns, and even death in high concentrations.

- Wear appropriate personal protective equipment (PPE) such as a respirator, gloves, and eye protection.

- Ensure proper ventilation in the work area to prevent ammonia buildup.

Mechanical Hazards

- High-pressure systems can rupture if not properly maintained.

- Follow all safety protocols for working with high-pressure equipment.

- Inspect the system regularly for leaks and damage.

3. What are the common problems encountered in ammonia refrigeration systems and how do you troubleshoot them?

- Leaks: Use a soap bubble solution to identify leaks. Repair leaks promptly to prevent ammonia loss and maintain system efficiency.

- Refrigerant charge issues: Insufficient or excessive refrigerant can affect system performance. Check refrigerant levels and adjust as necessary.

- Compressor problems: Vibration, noise, or overheating can indicate compressor issues. Inspect the compressor and its components, and seek professional repair if needed.

- Condenser fouling: Dirt and debris can accumulate on the condenser coils, reducing heat transfer efficiency. Clean the condenser regularly to maintain optimal performance.

- Evaporator icing: Restricted airflow or refrigerant flow can cause evaporator coils to ice up. Inspect the evaporator and ensure proper airflow and refrigerant distribution.

4. How do you perform a leak test on an ammonia refrigeration system?

- Evacuate the system using a vacuum pump.

- Charge the system with a small amount of nitrogen.

- Pressurize the system to a predetermined level.

- Monitor the system pressure over time. A drop in pressure indicates a leak.

- Use a soap bubble solution or electronic leak detector to locate the leak.

5. What is the purpose of an oil separator in an ammonia refrigeration system?

- Separates oil from the refrigerant, preventing oil buildup in the system.

- Protects the compressor from damage by reducing oil circulation.

- Improves system efficiency by ensuring the refrigerant is free of oil contaminants.

6. What are the different types of valves used in ammonia refrigeration systems?

- Expansion valve: Controls the flow of refrigerant into the evaporator.

- Suction stop valve: Isolates the compressor from the system during maintenance.

- Discharge stop valve: Isolates the condenser from the system during maintenance.

- Purging valve: Used to remove non-condensable gases from the system.

- Safety relief valve: Protects the system from excessive pressure buildup.

7. How do you calculate the refrigerant charge for an ammonia refrigeration system?

- Refer to the manufacturer’s specifications for the specific system.

- Use a refrigerant charge calculator based on factors such as system capacity, evaporator temperature, and condenser temperature.

- Use a rule of thumb of 0.25-0.35 lbs of ammonia per ton of refrigeration.

8. What are the environmental regulations terkait with ammonia refrigeration systems?

- EPA Section 608: Requires certification for technicians working with refrigerants.

- ASHRAE Standard 15: Sets safety standards for the design, installation, and operation of ammonia refrigeration systems.

- Local regulations: May vary depending on jurisdiction, so it’s important to be aware of any local codes or ordinances.

9. What is the difference between a reciprocating compressor and a centrifugal compressor?

Reciprocating Compressor

- Uses pistons to compress refrigerant in a cylinder.

- Positive displacement, providing high pressure ratios.

- Suitable for small to medium-sized systems.

Centrifugal Compressor

- Uses rotating impellers to accelerate and compress refrigerant.

- Dynamic compression, providing continuous flow.

- Suitable for large-capacity systems.

10. How do you maintain an ammonia refrigeration system to ensure optimal performance?

- Regularly check refrigerant levels and adjust as needed.

- Inspect and clean the condenser and evaporator coils to prevent fouling.

- Monitor system pressures and temperatures to identify any abnormalities.

- Check for leaks and repair promptly to prevent ammonia loss.

- Lubricate moving parts according to the manufacturer’s specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammonia Refrigeration Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammonia Refrigeration Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ammonia Refrigeration Technicians are responsible for the installation, maintenance, and repair of ammonia-based refrigeration systems. They must have a thorough understanding of the principles of refrigeration and the properties of ammonia.

1. Installation

Ammonia Refrigeration Technicians are responsible for installing new refrigeration systems. This includes selecting the appropriate equipment, sizing the system, and installing the components. They must also ensure that the system is properly charged with ammonia.

- Select and install ammonia-based refrigeration equipment

- Size and install piping, valves, and other system components

- Charge the system with ammonia and test for leaks

2. Maintenance

Ammonia Refrigeration Technicians are responsible for maintaining refrigeration systems to ensure that they are operating efficiently. This includes inspecting the system, cleaning the components, and replacing any worn or damaged parts. They must also monitor the system’s performance and make adjustments as necessary.

- Inspect system components for wear and tear

- Clean and lubricate system components

- Replace worn or damaged parts

- Monitor system performance and make adjustments as needed

3. Repair

Ammonia Refrigeration Technicians are responsible for repairing refrigeration systems that have broken down. This includes diagnosing the problem, replacing the faulty components, and testing the system to ensure that it is operating properly.

- Diagnose system problems

- Replace faulty components

- Test system to ensure proper operation

4. Safety

Ammonia is a hazardous material, so Ammonia Refrigeration Technicians must be aware of the potential risks and take precautions to ensure their safety. This includes wearing appropriate personal protective equipment, following safety procedures, and being aware of the signs and symptoms of ammonia exposure.

- Wear appropriate personal protective equipment

- Follow safety procedures when working with ammonia

- Be aware of the signs and symptoms of ammonia exposure

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for an Ammonia Refrigeration Technician position:

1. Research the company

Before you go to your interview, take some time to research the company. This will help you understand their business, their culture, and the specific role you are interviewing for. You can find information about the company on their website, social media pages, and in articles and news stories.

- Visit the company website to learn about their business, products, and services.

- Follow the company on LinkedIn to stay up-to-date on their latest news and announcements.

- Search for articles and news stories about the company to learn about their industry reputation.

2. Practice your answers

Once you have researched the company, take some time to practice answering common interview questions. This will help you feel more confident and prepared during your interview. Some common interview questions for Ammonia Refrigeration Technicians include:

- Why are you interested in this position?

- What are your qualifications for this position?

- What is your experience with ammonia refrigeration systems?

- What are some of the challenges you have faced in your previous role?

- What are your salary expectations?

3. Be prepared to talk about your experience

In your interview, the interviewer will want to know about your experience in the refrigeration industry. Be prepared to talk about your previous roles, the responsibilities you had, and the skills you developed. If you have any specific experience with ammonia refrigeration systems, be sure to highlight this in your interview.

- Describe your experience with installing, maintaining, and repairing refrigeration systems.

- Explain your knowledge of ammonia refrigeration systems and the safety precautions that must be taken when working with ammonia.

- Provide examples of your problem-solving skills and your ability to work independently and as part of a team.

4. Be professional

First impressions matter, so it is important to be professional in your interview. This includes dressing appropriately, being on time, and being respectful of the interviewer. It is also important to be positive and enthusiastic about the position.

- Dress appropriately for the interview.

- Be on time for your interview.

- Be respectful of the interviewer and answer their questions thoughtfully and concisely.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ammonia Refrigeration Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ammonia Refrigeration Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.