Are you gearing up for a career in Ammonia Still Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Ammonia Still Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

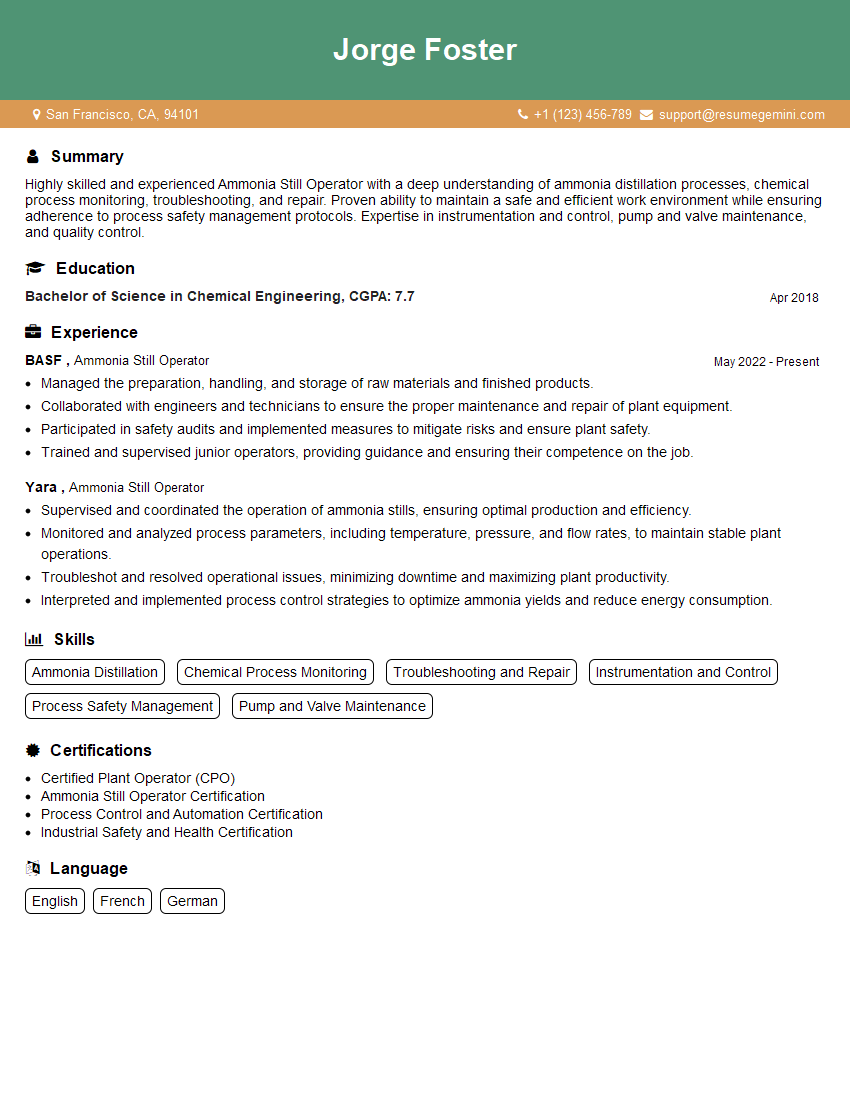

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammonia Still Operator

1. Describe the role and responsibilities of an Ammonia Still Operator.

- Operate, monitor, and maintain ammonia stills to produce high-purity ammonia gas.

- Monitor and adjust process parameters, such as temperature, pressure, and flow rates, to optimize production and minimize waste.

- Troubleshoot and resolve equipment malfunctions and process upsets.

- Maintain accurate records and documentation related to still operations.

- Ensure adherence to safety protocols and environmental regulations.

2. What key technical skills are required for this role?

Process Control and Monitoring

- Expertise in operating and controlling chemical processes, including knowledge of process variables, instrumentation, and control systems.

- Ability to interpret process data, identify deviations, and make real-time adjustments.

Equipment Maintenance

- Experience in troubleshooting and repairing pumps, compressors, heat exchangers, and other mechanical equipment.

- Understanding of electrical systems and instrumentation.

Safety and Compliance

- Thorough knowledge of safety protocols and procedures related to handling hazardous chemicals.

- Compliance with environmental regulations and industry best practices.

3. How do you ensure the safe and efficient operation of an ammonia still?

- Regularly inspect and maintain all equipment to prevent malfunctions.

- Monitor process parameters closely and make timely adjustments to maintain optimal operating conditions.

- Follow established safety procedures and wear appropriate personal protective equipment.

- Respond promptly to alarms and process upsets to minimize risks.

- Train and supervise personnel to ensure adherence to safety protocols and best practices.

4. Describe the process of troubleshooting and resolving equipment malfunctions in an ammonia still.

- Identify the source of the malfunction through observation, data analysis, and diagnostic tests.

- Determine the root cause of the issue, considering equipment failures, process upsets, or other factors.

- Develop and implement corrective actions, such as repairing or replacing components, adjusting process parameters, or modifying operating procedures.

- Monitor the situation closely after implementing the fix to ensure the problem is resolved and does not recur.

- Document the malfunction and the steps taken to resolve it for future reference.

5. How do you prioritize and manage multiple tasks and responsibilities effectively?

- Maintain a clear understanding of priorities by regularly reviewing work orders and production schedules.

- Use time management techniques, such as creating to-do lists and setting deadlines.

- Delegate tasks to team members when necessary and provide clear instructions and support.

- Communicate regularly with colleagues and supervisors to stay informed of progress and potential challenges.

- Stay organized and maintain a clean and efficient work environment.

6. How do you stay up-to-date with advancements in technology and best practices in the field?

- Attend industry conferences and workshops to learn about new technologies and developments.

- Read technical journals and articles to stay abreast of research and industry trends.

- Participate in online forums and discussions to engage with other professionals and exchange knowledge.

- Seek opportunities for professional development and training to enhance skills and knowledge.

- Network with peers and subject matter experts to stay informed about industry trends and best practices.

7. How do you measure and evaluate your performance as an Ammonia Still Operator?

- Regularly review production data and compare it to performance targets.

- Monitor downtime and identify areas for improvement in equipment maintenance and troubleshooting.

- Seek feedback from supervisors, colleagues, and customers to identify areas of strength and weakness.

- Participate in performance evaluations and self-assessments to identify opportunities for professional growth.

- Maintain a portfolio of accomplishments and documented improvements to demonstrate contributions to the organization.

8. How do you handle working in a fast-paced and demanding environment?

- Maintain a positive and proactive attitude even under pressure.

- Prioritize tasks and manage time effectively to meet deadlines.

- Stay calm and collected when dealing with unexpected situations.

- Communicate clearly and effectively with colleagues and supervisors to resolve issues promptly.

- Seek support from team members when needed to ensure smooth operations.

9. Describe your experience in working with hazardous chemicals and handling safety protocols.

- Thorough understanding of the properties and hazards of ammonia and other chemicals used in the process.

- Extensive experience in following established safety procedures and wearing appropriate personal protective equipment.

- Proficient in handling hazardous materials, including proper storage, transportation, and disposal.

- Participated in emergency response drills and training to ensure preparedness for potential incidents.

- Commitment to maintaining a safe and compliant work environment.

10. Why are you interested in this specific role and our company?

- Passion for the chemical industry and ammonia production.

- Interest in optimizing processes and improving efficiency.

- Alignment with the company’s values and commitment to safety and sustainability.

- Desire to contribute to the success of the team and organization.

- Belief that my skills and experience would be a valuable asset to the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammonia Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammonia Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ammonia Still Operators play a crucial role in the chemical processing industry, overseeing the safe and efficient operation of ammonia still equipment. Their primary responsibilities include:

1. Equipment Operation and Maintenance

Operating and monitoring ammonia stills, ensuring optimal performance and adherence to safety protocols.

- Regularly inspecting stills, pumps, valves and other critical equipment.

- Performing routine maintenance and repairs to maintain equipment efficiency.

2. Process Monitoring and Control

Continuously monitoring process variables, such as temperature, pressure, flow rate and product quality, and making necessary adjustments.

- Analyzing data to identify and resolve process deviations.

- Implementing corrective actions to stabilize the process and maintain product quality.

3. Emergency Response and Safety

Responding promptly to emergencies, such as leaks, spills, fires, or equipment malfunctions.

- Following established safety procedures and ensuring compliance with regulatory requirements.

- Using personal protective equipment and implementing proper safety measures.

4. Communication and Recordkeeping

Communicating effectively with colleagues, supervisors and other departments to coordinate operations and resolve issues.

- Maintaining accurate records of process parameters, maintenance activities and any incidents.

- Communicating process deviations, equipment malfunctions, and any potential hazards to the appropriate personnel.

Interview Tips

Preparing thoroughly for your interview will significantly increase your chances of success. Here are some valuable tips to help you ace your interview:

1. Research the Company and Position

Research the company’s background, industry, products, services and recent developments. Understand the specific requirements of the Ammonia Still Operator position and how your skills and experience align with them.

- Visit the company’s website, social media pages and industry publications.

- Read the job description carefully and identify the key responsibilities and skills required for the role.

2. Practice Your Answers

Anticipate potential interview questions and prepare thoughtful responses that highlight your relevant experience, skills and qualifications.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice your answers out loud to gain confidence and improve your delivery.

3. Be Enthusiastic and Personable

Enthusiasm and a positive attitude can make a significant impact on the interviewer. Demonstrate your passion for the role and the industry.

- Make eye contact, smile and show genuine interest in the company and the position.

- Be respectful and listen attentively to the interviewer’s questions.

4. Ask Thoughtful Questions

Asking insightful questions demonstrates your engagement and interest in the role and the company.

- Prepare questions related to the company’s growth plans, industry trends, or specific aspects of the Ammonia Still Operator position.

- Avoid asking questions that are easily found on the company’s website or in the job description.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ammonia Still Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.