Feeling lost in a sea of interview questions? Landed that dream interview for Ammonia Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ammonia Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

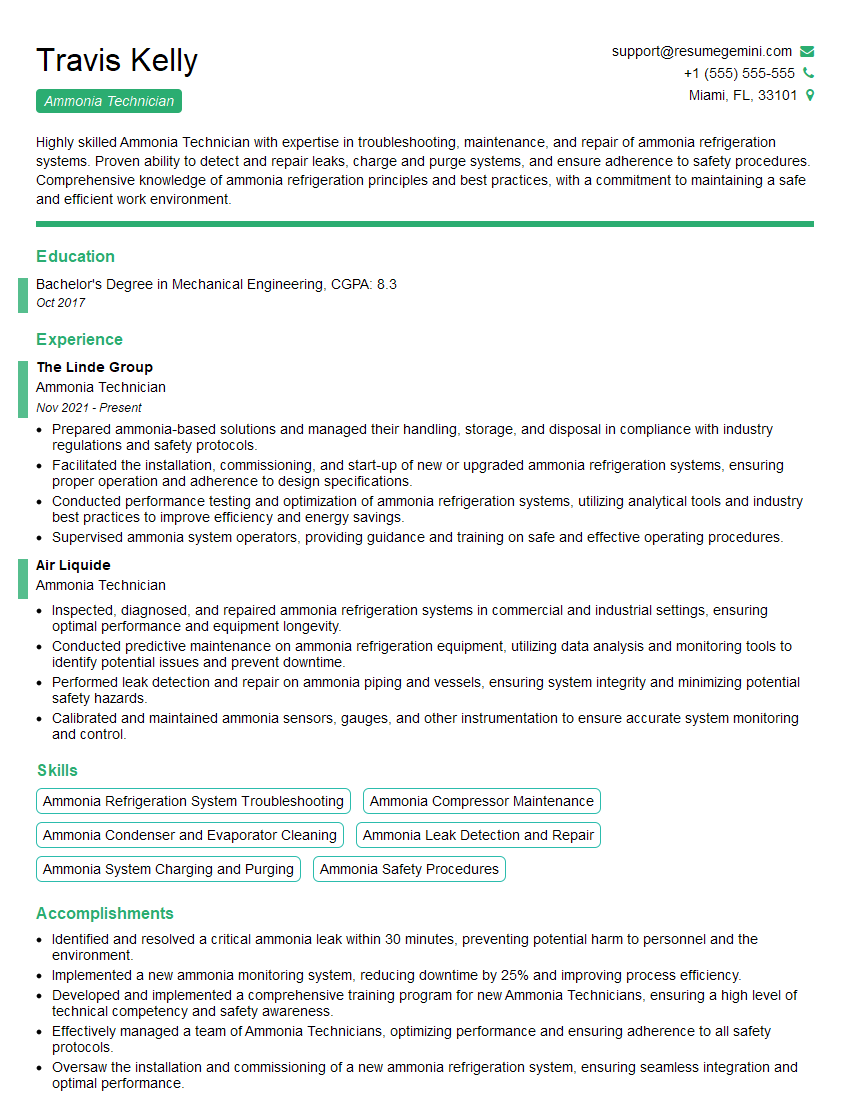

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammonia Technician

1. What are the key skills and responsibilities of an Ammonia Technician?

As an Ammonia Technician, key responsibilities include:

- Monitoring and maintaining ammonia refrigeration systems to ensure optimal performance and safety.

- Installing, repairing, and troubleshooting ammonia systems and components, including compressors, condensers, and evaporators.

- Performing routine inspections and preventive maintenance to identify and address potential issues.

- Responding to emergency situations involving ammonia leaks or system malfunctions.

Essential skills for this role encompass:

- Strong knowledge of ammonia refrigeration systems, including principles, components, and operation.

- Expertise in hands-on troubleshooting and repair techniques for ammonia systems.

- Proficiency in using specialized tools and equipment for ammonia handling and maintenance.

- Understanding and adherence to safety protocols and regulations related to ammonia handling.

2. Describe the different types of ammonia refrigeration systems and their applications.

Industrial Refrigeration Systems

- Large-scale systems used in food processing, chemical plants, and ice rinks.

- Involve complex designs with multiple compressors and evaporators.

Commercial Refrigeration Systems

- Smaller systems used in supermarkets, restaurants, and warehouses.

- Typically have single or dual compressors with self-contained units.

Comfort Cooling Systems

- Used in ice arenas and other large cooling applications.

- Involve specialized equipment for maintaining low temperatures and humidity control.

3. Explain the principles of operation of an ammonia refrigeration system.

Ammonia refrigeration systems operate on the vapor-compression cycle, which involves four main components:

- Compressor: Compresses low-pressure ammonia vapor to high pressure, increasing its temperature.

- Condenser: Cools and condenses the high-pressure ammonia vapor into liquid ammonia.

- Expansion Valve: Controls the flow of liquid ammonia into the evaporator.

- Evaporator: Absorbs heat from the refrigerated space, causing the liquid ammonia to evaporate into low-pressure vapor.

The evaporated ammonia then returns to the compressor, completing the cycle.

4. What are the safety precautions that must be taken when working with ammonia?

Working with ammonia requires strict adherence to safety protocols, including:

- Wearing appropriate personal protective equipment (PPE), including respirators, gloves, and eye protection.

- Ensuring adequate ventilation in work areas to prevent ammonia accumulation.

- Using leak detection equipment to monitor for potential leaks.

- Following emergency response procedures in case of leaks or spills.

- Properly disposing of ammonia waste according to environmental regulations.

5. How do you troubleshoot common problems in ammonia refrigeration systems?

Common problems in ammonia refrigeration systems include:

- Compressor failure: Check power supply, inspect for mechanical issues, measure pressures.

- Condenser fouling: Clean condenser coils, ensure proper airflow.

- Evaporator icing: Check refrigerant charge, airflow, and defrost system.

- Leaks: Use leak detection equipment, tighten connections, replace damaged components.

- System inefficiency: Monitor pressures, temperatures, and refrigerant charge, inspect components for wear or damage.

6. What are the different types of ammonia compressors and their advantages and disadvantages?

Reciprocating Compressors

- Advantages: Reliable, relatively low cost, easy to maintain.

- Disadvantages: Can be noisy and produce vibrations, limited capacity.

Screw Compressors

- Advantages: High efficiency, less noise and vibration, oil-free operation.

- Disadvantages: More complex design, higher initial cost.

Centrifugal Compressors

- Advantages: High capacity, suitable for large systems, smooth operation.

- Disadvantages: Requires high speed, can be less efficient at low loads.

7. How do you maintain and inspect ammonia refrigeration systems to ensure optimal performance?

Maintenance and inspection tasks include:

- Regularly cleaning condenser and evaporator coils.

- Checking refrigerant charge and adjusting as necessary.

- Monitoring system pressures and temperatures.

- Inspecting for leaks using leak detection equipment.

- Performing vibration analysis on compressors.

- Conducting oil analysis to monitor compressor health.

8. Describe the process of charging an ammonia refrigeration system.

Charging an ammonia refrigeration system involves:

- Evacuating the system to remove non-condensable gases.

- Slowly introducing liquid ammonia into the system while monitoring pressures.

- Adjusting the charge based on system capacity and operating conditions.

- Verifying the charge by observing system performance and pressures.

9. What are the environmental regulations and safety codes that apply to ammonia refrigeration systems?

Relevant regulations and codes include:

- Environmental Protection Agency (EPA) regulations on ammonia emissions.

- Occupational Safety and Health Administration (OSHA) standards for ammonia handling.

- American Society of Refrigerating and Air-Conditioning Engineers (ASHRAE) safety codes.

- Local and state building codes and fire codes.

10. What are the latest advancements in ammonia refrigeration technology?

- Development of low-charge ammonia systems.

- Integration of advanced control systems for energy efficiency.

- Research on natural refrigerants, such as ammonia, as alternatives to synthetic refrigerants.

- Focus on reducing ammonia emissions and improving safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammonia Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammonia Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ammonia Technicians are responsible for maintaining and troubleshooting refrigeration and air conditioning systems that utilize ammonia as a refrigerant. They play a crucial role in ensuring the efficient and safe operation of these systems in various industries, including food processing, cold storage, and industrial manufacturing.

1. System Maintenance and Troubleshooting

Diagnose and troubleshoot malfunctions in ammonia refrigeration and air conditioning systems.

- Conduct regular inspections of system components, including compressors, condensers, evaporators, and piping, to identify potential issues.

- Use specialized tools and equipment to test and analyze system performance, identifying areas of concern or potential failures.

- Repair or replace faulty components and resolve system issues to restore optimal functionality.

2. Ammonia Handling and Safety

Safely handle and manage ammonia as a refrigerant, ensuring compliance with environmental and safety regulations

- Follow established safety protocols for handling, storing, and disposing of ammonia to minimize risks.

- Monitor ammonia levels and maintain appropriate concentrations within the system, ensuring safe and efficient operation.

- Respond to ammonia leaks and other emergencies promptly, following established procedures to mitigate risks and protect personnel.

3. System Optimization and Energy Efficiency

Optimize system performance and improve energy efficiency, focusing on reducing operating costs while maintaining system reliability

- Analyze system data and identify areas for improvement, recommending modifications or upgrades to enhance efficiency.

- Implement energy-saving measures, such as optimizing condenser and evaporator temperatures, to reduce energy consumption.

- Provide training and support to other technicians on best practices for system operation and maintenance.

4. Regulatory Compliance and Documentation

Ensure compliance with relevant regulations and standards governing the use of ammonia in refrigeration and air conditioning systems

- Maintain accurate records of system maintenance, repairs, and inspections, as required by regulatory authorities.

- Stay up-to-date on industry best practices and technological advancements related to ammonia refrigeration.

- Coordinate with regulatory agencies and environmental protection organizations to ensure compliance and responsible handling of ammonia.

Interview Tips

Preparing for an interview for an Ammonia Technician position requires a thorough understanding of the job responsibilities and industry-specific knowledge. Here are some tips to help you ace the interview:

1. Research the Company and the Role

Before the interview, thoroughly research the company, their operations, and the specific role you’re applying for.

- Visit the company’s website and LinkedIn page to gather information about their business, culture, and team.

- Review the job description carefully and identify the key skills and experiences required for the position.

2. Highlight Your Technical Expertise

Showcase your technical skills and experience in ammonia refrigeration and air conditioning systems.

- Emphasize your knowledge of system components, refrigeration cycles, and troubleshooting techniques.

- Quantify your accomplishments, providing specific examples of how you have successfully diagnosed and repaired ammonia systems.

- Discuss your familiarity with relevant safety protocols and regulations related to ammonia handling.

3. Demonstrate Your Safety Commitment

Highlight your commitment to safety and your adherence to industry best practices for handling ammonia.

- Describe your experience in responding to ammonia leaks and other emergencies, emphasizing your ability to follow safety procedures.

- Discuss your knowledge of ammonia toxicity and the importance of proper handling techniques.

4. Emphasize Your Problem-Solving Abilities

Ammonia Technicians encounter various technical challenges on a regular basis. Demonstrate your problem-solving abilities.

- Provide examples of complex troubleshooting situations you have resolved effectively.

- Explain your analytical approach to identifying the root cause of system issues and developing solutions.

5. Show Your Willingness to Learn and Grow

The ammonia refrigeration industry is constantly evolving. Express your willingness to learn new technologies and best practices.

- Discuss your interest in staying up-to-date with industry advancements and attending technical training programs.

- Convey your eagerness to contribute your knowledge and skills to the team and the company.

Next Step:

Now that you’re armed with the knowledge of Ammonia Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ammonia Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini