Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ammonia Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

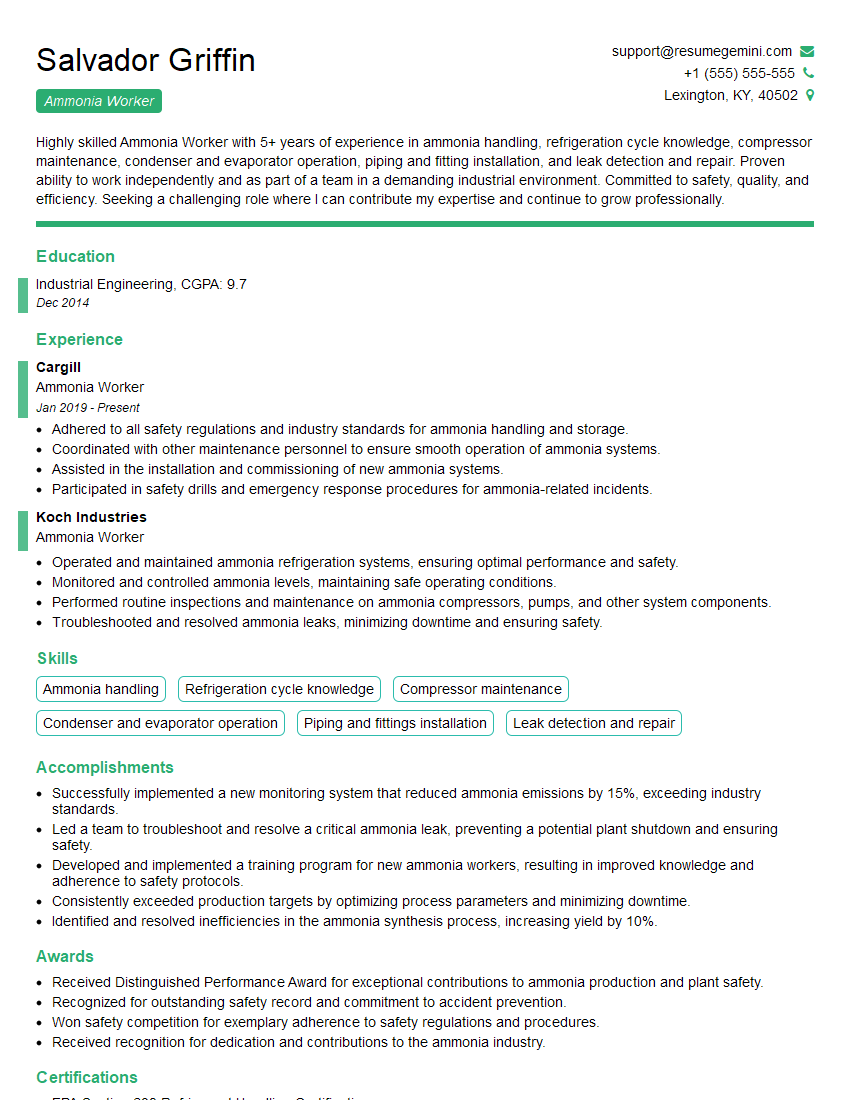

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammonia Worker

1. Describe the safety measures and precautions you take when working with ammonia.

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, and eye protection.

- Ensure the work area is well-ventilated.

- Handle ammonia containers carefully to avoid leaks.

- Know the location of emergency eyewash stations and showers.

- Follow all established safety protocols and procedures.

2. What are the different grades of ammonia and their uses?

Anhydrous ammonia

- Highest purity (99.99%+)

- Used in fertilizers, explosives, and refrigerants

Agricultural ammonia

- Typically 82% ammonia solution

- Used as a nitrogen fertilizer

Household ammonia

- Typically 5-10% ammonia solution

- Used as a cleaning agent and disinfectant

3. Explain the process of ammonia production.

- Natural gas or coal is reacted with steam to produce hydrogen and carbon dioxide.

- Hydrogen is reacted with nitrogen in a Haber-Bosch process to produce ammonia.

- Ammonia is then purified and compressed for storage and transportation.

4. What are the typical operating parameters for an ammonia plant?

- Pressure: 150-200 bar

- Temperature: 450-550°C

- Conversion rate: 97-99%

- Yield: 90-95%

5. Describe the key components of an ammonia plant.

- Feedstock preparation unit

- Primary reformer

- Secondary reformer

- Ammonia converter

- Purification unit

- Storage and loading facilities

6. What are the common troubleshooting issues in ammonia production?

- Catalyst deactivation

- Equipment failures

- Feedstock contamination

- Process upsets

7. Describe the role of instrumentation and control in ammonia production.

- Monitors process parameters

- Controls valves and pumps

- Provides early warning of potential problems

- Automates production processes

8. What are the environmental regulations governing ammonia production?

- Emissions controls for air pollutants (e.g., NOx, SOx)

- Wastewater treatment requirements

- Hazardous materials handling regulations

9. Describe the quality control procedures for ammonia production.

- Regular sampling and testing of feedstock and product

- Calibration of instrumentation

- Maintenance of production records

- Compliance with industry standards and regulations

10. What are the safety hazards associated with ammonia production?

- Toxic and corrosive gas

- Fire and explosion risks

- High pressure systems

- Slip and fall hazards

- Confined space hazards

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammonia Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammonia Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ammonia Workers play a crucial role in ensuring the safe and efficient operation of ammonia plants. Their primary responsibilities involve:

1. Production and Maintenance of Ammonia Equipment

Ammonia Workers oversee the production and maintenance of ammonia-related equipment, including converters, reformers, separators, and storage tanks. They monitor and control process parameters, such as temperature, pressure, and flow rates, to optimize plant efficiency and prevent equipment failures.

2. Plant Monitoring and Control

They continuously monitor plant operations through control panels and gauges to identify any deviations or potential hazards. They promptly respond to alarms and take corrective actions to ensure the smooth flow of production and prevent accidents.

3. Safety and Environmental Compliance

Ammonia Workers prioritize safety in the workplace. They adhere to all safety protocols, wear appropriate protective gear, and follow established procedures to prevent accidents and protect the environment. They are also responsible for maintaining a clean and organized work area.

4. Troubleshooting and Problem-Solving

When problems or unexpected situations arise, Ammonia Workers effectively troubleshoot and resolve issues. They analyze data, identify root causes, and implement appropriate solutions to minimize downtime and maintain production efficiency.

Interview Tips

To ace an Ammonia Worker interview, candidates should prepare thoroughly by focusing on the following key areas:

1. Technical Knowledge and Experience

Highlight your knowledge of ammonia production processes, equipment maintenance, safety regulations, and environmental compliance. Provide specific examples of your hands-on experience in operating and maintaining ammonia plants.

2. Problem-Solving and Troubleshooting

Emphasize your ability to identify and resolve issues in a timely and efficient manner. Share examples of how you successfully diagnosed and fixed problems in previous roles.

3. Safety and Compliance

Demonstrate your commitment to safety and compliance. Explain your understanding of industry safety standards and best practices. Highlight your experience in implementing and adhering to safety protocols.

4. Teamwork and Communication

Ammonia Workers often work in teams. Highlight your teamwork skills and provide examples of how you effectively collaborate with colleagues to achieve project goals.

5. Research the Company

Before the interview, research the company and its ammonia operations. Learn about their specific production processes, safety protocols, and environmental initiatives. Showing that you are knowledgeable about the company will impress the interviewers.

6. Dress Professionally and Be Punctual

First impressions matter. Dress professionally for the interview and arrive on time. Punctuality and appropriate attire demonstrate respect for the interviewer’s time.

7. Practice and Prepare Questions

Practice answering common interview questions related to ammonia production, safety, and troubleshooting. Prepare thoughtful questions to ask the interviewer about the company and the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ammonia Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.