Are you gearing up for an interview for a Ammonium Nitrate Crystallizer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ammonium Nitrate Crystallizer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

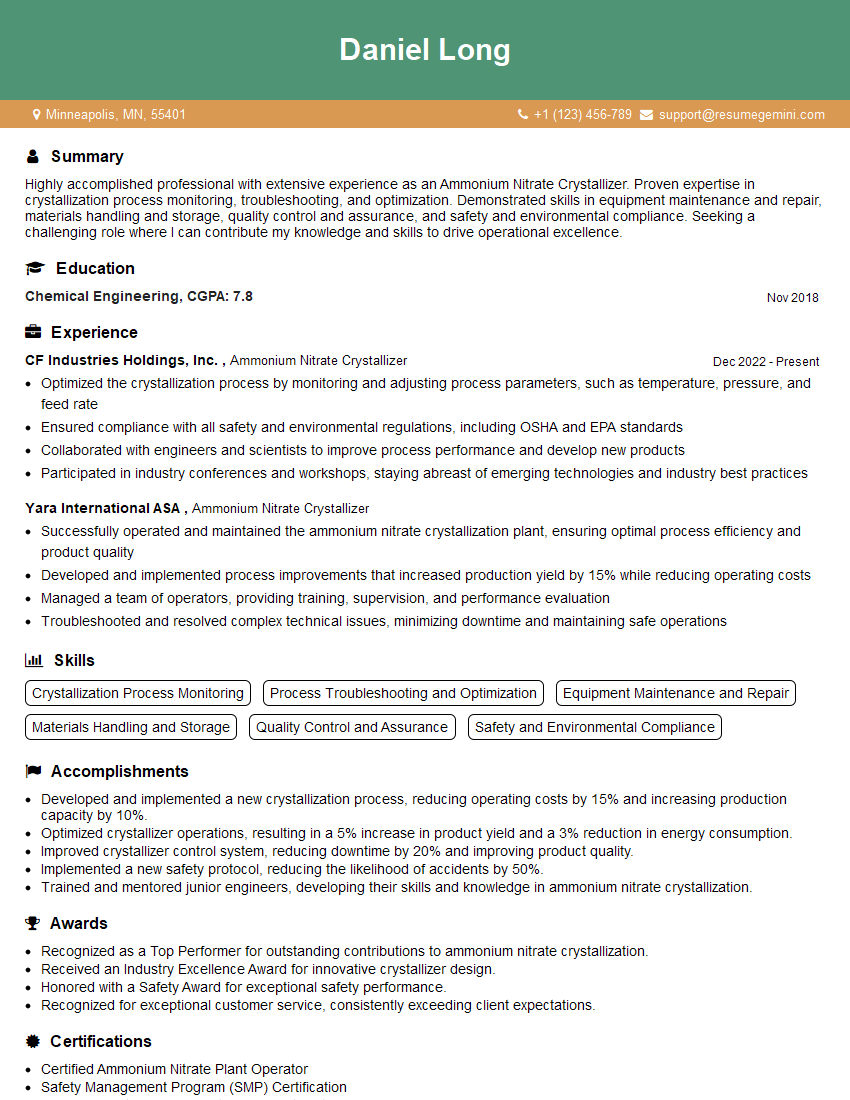

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammonium Nitrate Crystallizer

1. Describe the process of ammonium nitrate crystallization in detail?

The ammonium nitrate crystallization process involves several steps:

- Preparation of the feed solution: Ammonium nitrate is dissolved in water to create a concentrated solution.

- Cooling and evaporation: The solution is cooled to its saturation point, and water is evaporated to increase the concentration further.

- Crystallization: The concentrated solution is introduced into a crystallizer, where it is agitated to promote crystal formation. Seed crystals are added to initiate the crystallization process.

- Growth and separation: The crystals grow by accumulating ammonium nitrate molecules from the solution. The crystals are separated from the mother liquor using a centrifuge or filter.

- Drying and packaging: The separated crystals are dried to remove any remaining moisture, then packaged for storage or transportation.

2. What are the key parameters that need to be monitored and controlled during the ammonium nitrate crystallization process?

Temperature

- Temperature affects the solubility of ammonium nitrate, so it must be closely controlled to maintain the desired supersaturation level.

Agitation

- Agitation is crucial for providing uniform mixing, promoting crystal growth, and preventing agglomeration.

Residence time

- Residence time determines the extent of crystallization and the crystal size distribution.

pH

- pH can influence the solubility and crystal morphology of ammonium nitrate.

3. How do you optimize the yield and quality of ammonium nitrate crystals?

Optimizing yield and quality involves:

- Controlled cooling and evaporation: Gradual cooling and controlled evaporation prevent the formation of small or non-uniform crystals.

- Appropriate agitation: Optimizing agitation ensures sufficient contact between the solution and the crystals, promoting uniform growth.

- Seed crystal selection: The size, shape, and purity of seed crystals influence the final crystal properties.

- Residence time optimization: Adjusting residence time allows for better control of crystal growth and prevents excessive agglomeration.

- pH adjustment: Maintaining an optimal pH range promotes crystal formation and prevents impurities.

4. What are the common problems encountered during ammonium nitrate crystallization, and how do you troubleshoot them?

Common problems include:

- Excessive crystal agglomeration: This can be addressed by adjusting agitation conditions or adding anti-agglomeration agents.

- Formation of fines: Fines can be minimized by optimizing cooling rates, agitation, and seed crystal selection.

- Impurities in the crystals: Impurities can be controlled by purifying the feed solution and optimizing crystallization conditions.

- Equipment malfunction: Maintaining equipment regularly and following proper operating procedures can prevent these issues.

5. Describe the safety precautions that need to be taken when handling ammonium nitrate?

Ammonium nitrate is a potentially explosive material, so safety precautions are crucial:

- Storage and handling: Store in a cool, dry place away from heat sources and ignition sources. Avoid contact with incompatible materials, such as fuels and acids.

- Personal protective equipment: Wear appropriate PPE, including gloves, safety glasses, and a dust mask, when handling ammonium nitrate.

- Fire safety: Keep fire extinguishers and water sources nearby and follow proper firefighting procedures in case of a fire.

- Spill response: Contain spills immediately and neutralize with water or a neutralizing agent.

6. What are the environmental regulations that must be followed when operating an ammonium nitrate crystallization plant?

Environmental regulations vary depending on the location of the plant:

- Air emissions: Control measures must be in place to minimize the release of ammonia, nitrogen oxides, and particulate matter.

- Water discharge: The plant must comply with wastewater discharge standards to prevent contamination of water bodies.

- Solid waste management: Proper disposal of solid waste, such as spent catalyst and filter cakes, must be ensured to prevent environmental contamination.

7. Describe the role of crystallization in the production of ammonium nitrate for industrial use?

Crystallization is crucial in ammonium nitrate production for several reasons:

- Purification: Crystallization allows for the removal of impurities and the production of high-purity ammonium nitrate.

- Control of crystal size and shape: The crystallization process can be optimized to produce crystals with the desired size and shape, which is important for specific industrial applications.

- Improved handling and storage: Crystalline ammonium nitrate is easier to handle, transport, and store compared to liquid or molten forms.

8. How do you ensure the quality of ammonium nitrate crystals produced in your plant?

Quality assurance measures include:

- Process control: Monitoring and controlling critical process parameters, such as temperature, agitation, and residence time.

- Product testing: Regular testing of the crystals to ensure they meet specifications for purity, crystal size, and other quality attributes.

- Equipment maintenance: Regular maintenance and calibration of equipment to prevent deviations and ensure consistent product quality.

- Employee training: Ensuring that operators are well-trained and follow proper operating procedures.

9. Describe the recent advancements in ammonium nitrate crystallization technology?

Advancements include:

- Continuous crystallization: Continuous processes offer improved efficiency and reduced operating costs.

- Advanced control systems: Automated control systems enhance process stability and product quality.

- Use of computational fluid dynamics (CFD): CFD modeling helps optimize crystallizer design and operating conditions.

- Novel crystallization techniques: Techniques such as ultrasonic crystallization and microwave-assisted crystallization have shown promising results.

10. What are the challenges faced in the ammonium nitrate crystallization industry?

Challenges include:

- Safety concerns: The explosive nature of ammonium nitrate requires strict safety measures and adherence to regulations.

- Environmental regulations: Increasingly stringent environmental regulations demand efficient and sustainable production processes.

- Market fluctuations: The demand for ammonium nitrate is influenced by factors such as agricultural practices and geopolitical events.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammonium Nitrate Crystallizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammonium Nitrate Crystallizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of an Ammonium Nitrate Crystallizer

An Ammonium Nitrate Crystallizer is responsible for operating and maintaining a crystallization plant that produces ammonium nitrate crystals for various industrial applications. The key job responsibilities include:

1. Crystallization Process Management

Controlling and monitoring the crystallization process by adjusting various parameters such as temperature, pressure, and flow rates to ensure optimal crystal formation.

- Monitoring the temperature, pH level, and conductivity of the feed solution.

- Adjusting the feed rate to maintain desired supersaturation levels and prevent premature crystallization.

- Ensuring proper mixing and agitation to promote crystal growth.

2. Crystallizer Maintenance and Troubleshooting

Performing regular maintenance on the crystallizer, including cleaning, inspecting, and replacing parts to ensure smooth operation.

- Inspecting and cleaning the crystallizer vessel, pumps, and pipelines.

- Identifying and resolving potential issues with the equipment, such as blockages, leaks, or breakdowns.

- Maintaining accurate records of maintenance activities and any repairs or modifications performed.

3. Quality Assurance

Monitoring and ensuring the quality of the ammonium nitrate crystals produced by the plant.

- Conducting regular quality checks on the crystal size, shape, and purity.

- Implementing quality control measures to prevent contamination or defects in the crystals.

- Maintaining quality standards and documentation related to the production process.

4. Safety Compliance

Adhering to all safety protocols and regulations related to the operation of a crystallization plant.

- Wearing appropriate personal protective equipment (PPE) while operating the crystallizer.

- Following established safety procedures for handling chemicals, equipment, and waste.

- Maintaining a clean and organized work environment to prevent accidents.

Interview Tips for an Ammonium Nitrate Crystallizer

To prepare for an interview as an Ammonium Nitrate Crystallizer, it is important to:

1. Understand the Industry and Job Duties

Research the chemical industry, specifically the production of ammonium nitrate crystals, and gain a thorough understanding of the key job responsibilities described above.

- Review industry publications, articles, and technical documents.

- Network with professionals working in similar roles to gather insights and perspectives.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience in operating and maintaining crystallization equipment.

- Quantify your accomplishments in previous roles, such as increasing crystal quality or reducing maintenance costs.

- Demonstrate your understanding of process control, automation, and troubleshooting techniques.

3. Prepare for Technical Questions

Expect questions related to the crystallization process, crystallizer maintenance, and quality control procedures.

- Review basic principles of crystallization, including supersaturation, nucleation, and growth.

- Practice troubleshooting common issues that may arise during the crystallization process.

4. Research the Company and Position

Learn about the company’s history, industry presence, and the specific role you are applying for.

- Visit the company’s website and explore their products, services, and mission statement.

- Read news articles and industry reports to stay informed about the company’s recent developments.

Next Step:

Now that you’re armed with the knowledge of Ammonium Nitrate Crystallizer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ammonium Nitrate Crystallizer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini