Are you gearing up for an interview for a Ammunition Assembly Laborer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ammunition Assembly Laborer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

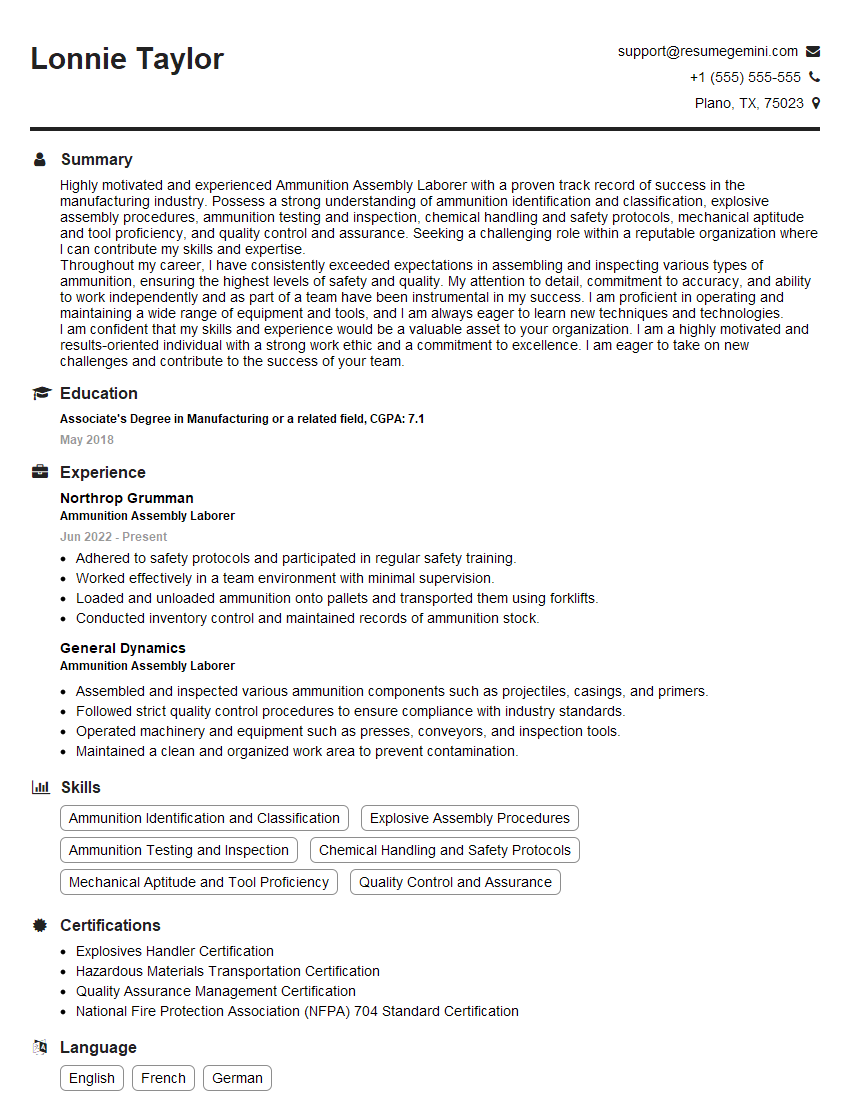

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammunition Assembly Laborer

1. What are the primary responsibilities of an Ammunition Assembly Laborer?

As an Ammunition Assembly Laborer, my key responsibilities involve:

- Assembling and inspecting ammunition components to ensure accuracy and quality.

- Operating machinery and equipment used in the assembly process, following established procedures.

- Performing quality control checks and inspections to identify and correct any discrepancies.

- Maintaining a clean and organized work area, adhering to safety protocols and regulations.

- Collaborating with other team members to ensure efficient and timely production.

2. Describe the steps involved in assembling a particular type of ammunition, such as small-caliber rounds.

Pre-Assembly Inspection

- Inspect components (e.g., bullet, propellant, case) for defects or damage.

- Ensure all parts meet specifications.

Case Preparation

- Clean and lubricate the case to reduce friction.

- Ensure proper primer seating.

Propellant Weighing and Loading

- Weigh and verify propellant charge against specifications.

- Load propellant into the case using specialized equipment.

Bullet Insertion

- Insert bullet into the case and ensure proper alignment.

- Apply appropriate force to seat the bullet securely.

Crimping and Final Inspection

- Crimp the case mouth to secure the bullet and prevent it from moving.

- Perform final inspection to verify assembly accuracy, dimensions, and overall quality.

3. What quality control procedures do you follow to ensure the safety and reliability of ammunition?

- Adhere to established quality standards and specifications.

- Conduct regular inspections and testing at various stages of the assembly process.

- Monitor equipment and machinery to ensure optimal performance.

- Document all quality control checks and inspections for traceability.

- Report any deviations from specifications or potential safety concerns promptly.

4. How do you handle and store ammunition safely to prevent accidents or incidents?

I follow strict safety protocols to prevent accidents or incidents when handling and storing ammunition:

- Wear appropriate personal protective equipment (PPE), including gloves and eye protection.

- Store ammunition in secure, dedicated areas that are well-ventilated and temperature-controlled.

- Handle ammunition with care, avoiding any impact or excessive force.

- Never point ammunition at anyone or towards unauthorized areas.

- Report any damaged, defective, or potentially hazardous ammunition immediately.

5. What is your experience with operating machinery and equipment used in ammunition assembly?

I have worked with a variety of machinery and equipment in ammunition assembly, including:

- Preloading presses for loading propellant into cases.

- Bullet seating machines for inserting bullets into cases.

- Crimping machines for securing bullets and preventing case expansion.

- Inspection equipment such as gauges, microscopes, and X-ray machines.

I am proficient in operating these machines safely and efficiently, following established procedures and specifications.

6. How would you respond if you discovered an assembly error or potential safety hazard during production?

- Immediately cease production and secure the affected area.

- Notify supervisor or qualified personnel about the error or hazard.

- Follow established procedures for reporting and investigating the incident.

- Assist in identifying and implementing corrective actions to prevent recurrence.

- Document the incident thoroughly, including the error or hazard, actions taken, and any recommendations.

7. What are your strengths as an Ammunition Assembly Laborer?

- Strong attention to detail and accuracy.

- Proficient in following established procedures and specifications.

- Ability to work independently and as part of a team.

- Experience operating machinery and equipment safely and efficiently.

- Committed to maintaining a clean and organized work area.

- Dedication to ensuring the safety and reliability of ammunition.

8. How do you stay up-to-date with industry best practices and advancements in ammunition assembly?

- Regularly attend industry workshops and seminars.

- Read technical publications and articles related to ammunition assembly.

- Participate in online forums and discussions with other professionals.

- Seek opportunities for on-the-job training and professional development.

- Consult with subject matter experts and manufacturers to gain knowledge and insights.

9. How do you prioritize and manage multiple tasks in a fast-paced production environment?

- Develop and follow a clear work schedule, prioritizing tasks based on urgency and importance.

- Break down large tasks into smaller, manageable steps.

- Delegate tasks to other team members when appropriate.

- Use effective time management techniques, such as the Pomodoro Technique.

- Maintain open communication with supervisors and colleagues to coordinate efforts and avoid overlap.

10. How do you handle working in a high-pressure environment where mistakes can have serious consequences?

In high-pressure environments, I remain calm and focused by:

- Thoroughly reviewing instructions and procedures before starting any task.

- Taking breaks when necessary to clear my mind and reduce stress.

- Communicating openly with my supervisor and colleagues about any concerns or challenges.

- Practicing mindfulness techniques to stay present and reduce anxiety.

- Prioritizing safety and accuracy over speed, taking the necessary time to complete tasks correctly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammunition Assembly Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammunition Assembly Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ammunition Assembly Laborers play a crucial role in ensuring the safety, reliability, and effectiveness of ammunition. They perform a variety of tasks related to the production, handling, and storage of ammunition items.

1. Assembly and Preparation

Assemble ammunition components, including projectiles, casings, and fuses, following established procedures and specifications.

- Verify component dimensions and specifications using measuring tools and gauges.

- Lubricate and clean components and tools to ensure smooth operation.

2. Testing and Inspection

Perform visual and functional inspections of completed ammunition items to detect defects or discrepancies.

- Adhere to established quality control standards and procedures.

- Report any irregularities or non-conformances to supervisors.

3. Handling and Storage

Transport and store ammunition items safely and securely according to established protocols.

- Use appropriate handling equipment and storage systems to minimize risks.

- Maintain a clean and well-organized work area, and ensure proper ventilation.

4. Compliance and Safety

Adhere to all applicable regulations, safety protocols, and procedures related to ammunition handling and storage.

- Wear appropriate personal protective equipment (PPE) and follow established safety guidelines.

- Understand and implement accident prevention measures.

Interview Tips

Preparing for an interview for an Ammunition Assembly Laborer position can increase your chances of success. Here are some interview tips and hacks to help you ace the interview:

1. Research the Company and Job

Familiarize yourself with the company’s background, mission, and products. Understand the specific requirements of the Ammunition Assembly Laborer role.

- Visit the company’s website and social media pages.

- Read job descriptions and company announcements.

2. Highlight Relevant Skills and Experience

Emphasize your previous experience in ammunition assembly or related fields. Showcase your skills in assembly, inspection, and safety.

- Quantify your accomplishments using specific examples.

- Explain how your skills and experience align with the job requirements.

3. Demonstrate Attention to Detail and Safety

Highlight your meticulous approach to assembly and inspection tasks. Emphasize your understanding of safety protocols and your commitment to accident prevention.

- Share examples of how you ensured accuracy and quality in your previous work.

- Explain your understanding of industry safety regulations.

4. Be Prepared for Technical Questions

Expect questions about ammunition components, assembly processes, and inspection techniques. Brush up on your knowledge and be ready to demonstrate your technical understanding.

- Review common types of ammunition and their components.

- Practice describing assembly and inspection procedures.

5. Practice Answering Behavioral Questions

Interviewers often ask behavioral questions to assess your problem-solving abilities and work style. Prepare examples of how you handled challenges and demonstrated teamwork.

- Use the STAR method to structure your answers (Situation, Task, Action, Result).

- Focus on positive outcomes and how your actions contributed to the success.

6. Dress Professionally and Arrive Punctually

First impressions matter. Dress appropriately for the interview and arrive on time. This shows respect for the interviewer and demonstrates your professionalism.

- Choose attire that is clean, pressed, and business-casual.

- Arrive at the interview location 15-20 minutes early to allow for any unforeseen delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ammunition Assembly Laborer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.