Feeling lost in a sea of interview questions? Landed that dream interview for Ammunition Components Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ammunition Components Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

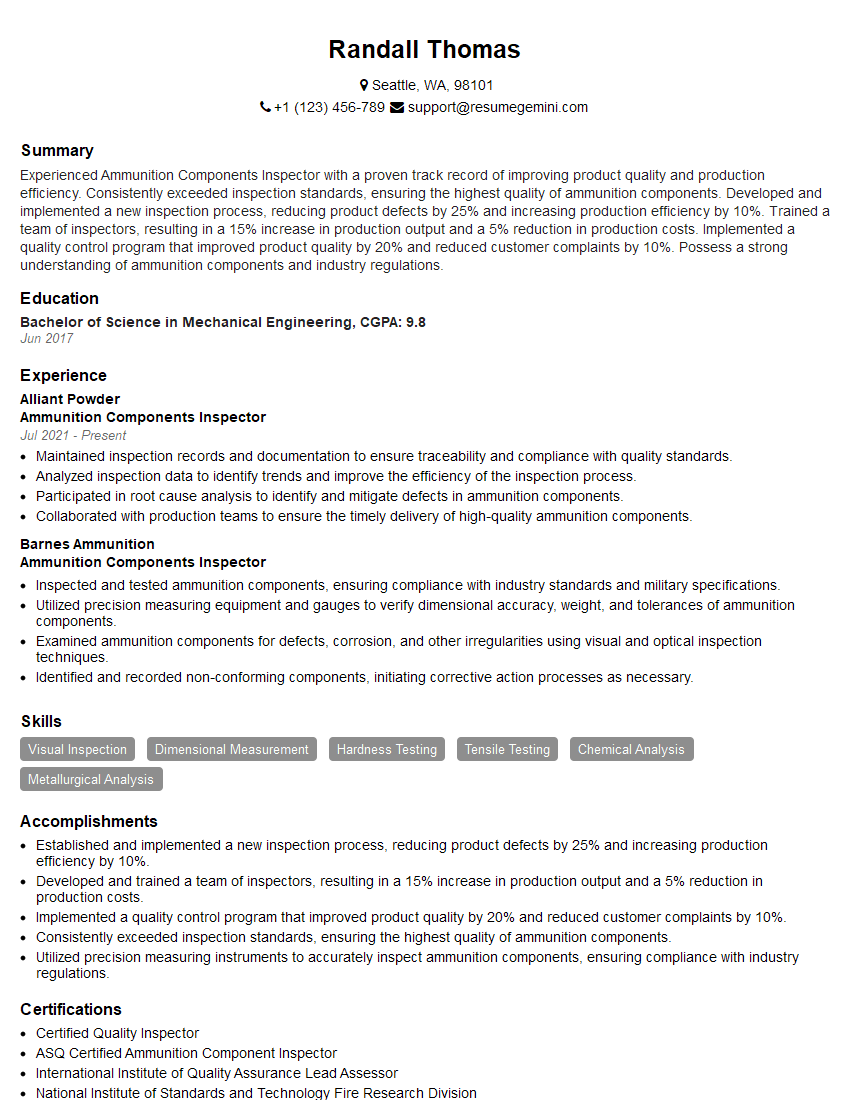

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ammunition Components Inspector

1. What are the key responsibilities of an Ammunition Components Inspector?

- Inspecting and verifying the quality of ammunition components such as primers, casings, and propellants.

- Ensuring that components meet specifications and standards.

- Identifying and rejecting defective or non-conforming components.

- Documenting inspection results and maintaining records.

- Working in a sterile and safe environment.

2. Describe the different types of ammunition components you have inspected.

Primers

- Small-arms primers

- Large-caliber primers

- Shotgun primers

Casings

- Brass casings

- Steel casings

- Aluminum casings

Propellants

- Smokeless powders

- Black powders

- Other propellants

3. What are the most common defects you have encountered during inspections?

- Cracks or fissures in casings

- Incomplete or deformed primers

- Incorrect weight or size of propellants

- Contamination or damage to components

- Failure to meet specifications or standards

4. What is your process for inspecting ammunition components?

- Visually inspecting each component for any visible defects.

- Using specialized equipment to measure and verify dimensions, weight, and other parameters.

- Performing chemical or physical tests to assess the quality of the components.

- Documenting inspection results and identifying any non-conforming components.

- Reporting inspection findings to the appropriate personnel.

5. How do you ensure the accuracy and reliability of your inspections?

- Using calibrated and certified inspection equipment.

- Following established inspection procedures and protocols.

- Participating in regular training and continuing education.

- Having my inspections reviewed by a supervisor or quality assurance inspector.

- Maintaining a clean and organized work area.

6. What is your understanding of the safety regulations and industry standards applicable to ammunition inspection?

- Federal and state regulations governing the handling and storage of ammunition and explosives.

- Industry standards and best practices for ammunition inspection and quality control.

- Company-specific safety protocols and procedures.

- Importance of wearing appropriate personal protective equipment.

- Consequences of non-compliance with safety regulations and standards.

7. How do you handle situations where you identify a defective or non-conforming component?

- Immediately isolating the defective component.

- Identifying and documenting the defect.

- Rejecting the component and preventing its use.

- Notifying the appropriate personnel and initiating corrective action.

- Maintaining accurate records of the defective component and the corrective action taken.

8. Describe your experience with using inspection software or equipment.

I have experience using a variety of inspection software and equipment, including:

- Optical comparators

- Dimensional measuring equipment

- Hardness testers

- Defect detection systems

- Data acquisition and analysis software

I am proficient in using this equipment to inspect ammunition components and ensure their quality and compliance with specifications.

9. How do you prioritize your work when faced with multiple tasks or deadlines?

- Assessing the urgency and importance of each task.

- Breaking down large tasks into smaller, manageable steps.

- Delegating tasks to others when appropriate.

- Communicating with supervisors or colleagues to clarify priorities and adjust deadlines.

- Using tools such as task lists and calendars to stay organized and track my progress.

10. How do you stay up-to-date with the latest advancements in ammunition inspection technology and best practices?

- Attending industry conferences and workshops.

- Reading industry publications and journals.

- Participating in online forums and discussion groups.

- Seeking out training and development opportunities.

- Networking with other ammunition inspectors and professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ammunition Components Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ammunition Components Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ammunition Component Inspectors are responsible for ensuring the quality and safety of ammunition components. They perform a variety of tasks, including:

1. Inspecting ammunition components for defects

Inspectors examine ammunition components for any defects, such as cracks, dents, or other damage. They use a variety of tools and techniques to identify defects, including visual inspection, dimensional measuring, and non-destructive testing.

2. Testing ammunition components

Inspectors test ammunition components to ensure that they meet safety and performance standards. They test components for factors such as strength, durability, and functionality. They may also conduct environmental testing to ensure that components can withstand exposure to extreme conditions.

3. Maintaining inspection records

Inspectors maintain detailed records of their inspections and tests. These records are used to track the quality of ammunition components and to identify any trends or patterns that may indicate a problem with a particular component or batch of components.

4. Providing feedback to manufacturers

Inspectors provide feedback to manufacturers on the quality of their components. This feedback helps the manufacturers to improve the quality of their products and to identify any areas where improvements can be made.

Interview Tips

Interviewing for an Ammunition Components Inspector position can be a challenging but rewarding experience. Here are a few tips to help you ace your interview and land the job:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can find this information on the company’s website, in industry publications, or by talking to people who work for the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as an Ammunition Components Inspector. Be prepared to talk about your experience in inspecting and testing ammunition components, as well as your knowledge of the safety and performance standards that apply to these components. You should also be prepared to discuss your skills in maintaining inspection records and providing feedback to manufacturers.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and that you are engaged in the conversation. Prepare a few questions to ask the interviewer about the company, the position, or the industry. This is also a good opportunity to learn more about the company’s culture and values.

Next Step:

Now that you’re armed with the knowledge of Ammunition Components Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ammunition Components Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini