Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Angle Bender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

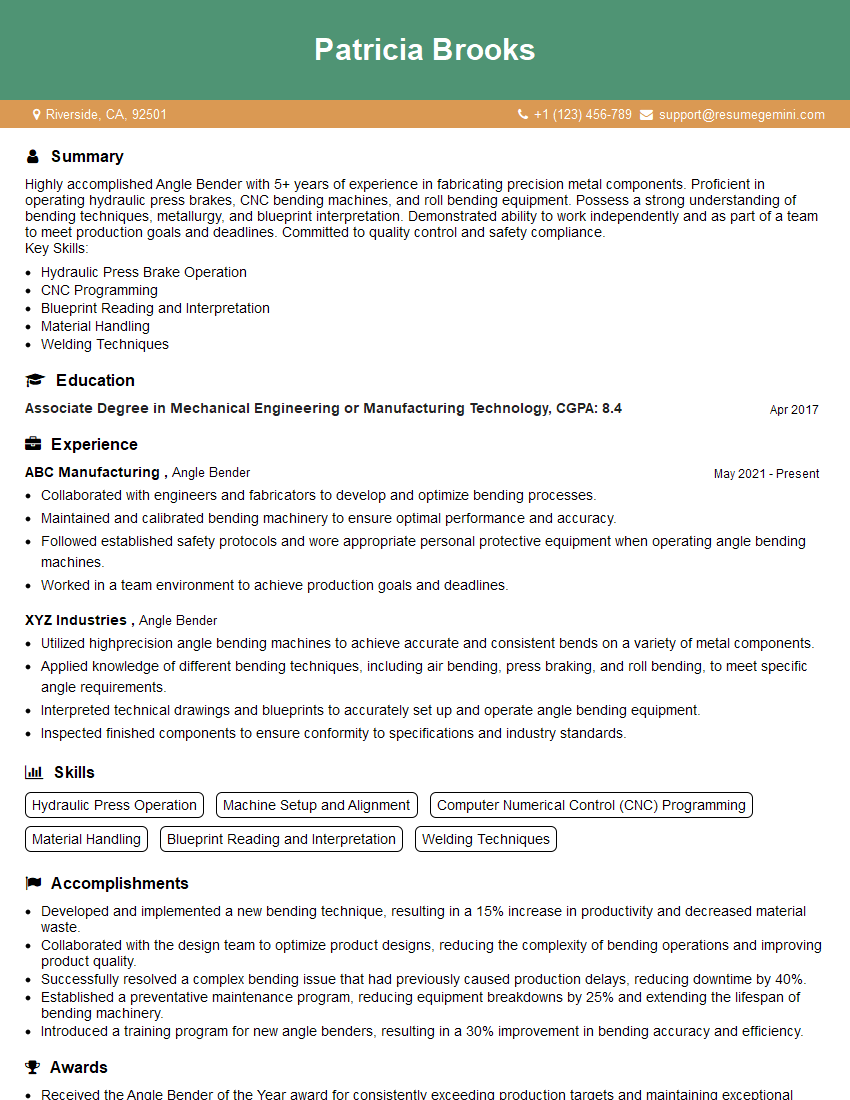

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Angle Bender

1. Tell me about your experience in bending angles?

In my previous role as an Angle Bender at [Previous Company Name], I was responsible for accurately bending angles according to specified dimensions and tolerances. I have extensive experience in using various angle bending machines, including manual and CNC-controlled models. I am proficient in handling different types of materials, including mild steel, stainless steel, and aluminum. I have a strong understanding of angle bending techniques and can consistently achieve precise results.

2. How do you ensure the accuracy of your bends?

Quality Control Measures

- I use precision measuring tools, such as angle gauges and protractors, to verify the accuracy of my bends.

- I follow established quality control procedures to ensure that all bends meet the required specifications.

Technical Expertise

- I have a deep understanding of the bending process and the factors that affect bend accuracy, such as material properties, machine settings, and tooling selection.

- I am skilled in using specialized software to calculate bend angles and create bend programs for CNC machines.

3. What are some of the challenges you have faced in bending angles?

One of the main challenges I have faced is bending complex angles, especially those with tight tolerances. To overcome this, I use advanced bending techniques, such as air bending and bottom bending, and carefully select the appropriate tooling. I also work closely with engineers and designers to ensure that the designs are feasible and can be accurately bent.

4. How do you handle bending angles for different types of materials?

Different materials have different properties that affect the bending process. For example, stainless steel requires more force to bend than mild steel. I adjust the machine settings, tooling, and bending techniques accordingly to ensure that I achieve the desired results. I also have experience in bending exotic materials, such as titanium and Inconel, which require specialized knowledge and equipment.

5. What safety precautions do you take when bending angles?

- I always wear appropriate personal protective equipment, such as safety glasses, gloves, and earplugs.

- I inspect the machine and tooling before each use to ensure they are in good working condition.

- I follow established safety protocols and procedures to minimize the risk of accidents or injuries.

6. What are some of the latest advancements in angle bending technology?

- Computer-controlled bending machines with advanced software capabilities

- Laser-guided bending systems for increased accuracy and efficiency

- Roll bending machines for bending large or complex shapes

I am eager to stay updated on these advancements and explore their potential to enhance my skills and productivity.

7. How do you keep up with the latest industry standards and best practices in angle bending?

- Attend industry conferences and workshops

- Read technical publications and articles

- Participate in online forums and discussions

I am committed to continuous learning and improving my knowledge and skills to deliver exceptional results.

8. What are your strengths and weaknesses as an Angle Bender?

Strengths

- Precision and accuracy in bending angles

- Expertise in handling various materials and bending techniques

- Strong understanding of quality control and safety procedures

Weaknesses

- Limited experience in bending exotic materials

- Still developing proficiency in programming and operating CNC bending machines

I am actively working on addressing my weaknesses through training and hands-on experience.

9. Why are you interested in working as an Angle Bender for our company?

I am highly interested in working as an Angle Bender for your company because I believe my skills and experience align well with your requirements. Your company’s reputation for producing high-quality metal fabrications and your commitment to innovation are impressive. I am eager to contribute my expertise to your team and help drive your success.

10. Do you have any questions for me about the role or our company?

I am interested in learning more about your company’s approach to quality control and the specific projects that Angle Benders are involved in.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Angle Bender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Angle Bender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for Angle Benders

Angle benders play a crucial role in metal fabrication, shaping sheet metal materials into precise angles and curvatures. Their responsibilities include:

1. Bending and Shaping Metal

Using specialized equipment, angle benders bend and shape metal sheets into various angles and shapes, ensuring accuracy and precision.

- Operate and adjust angle bending machines to achieve desired angles and curvatures.

- Set up and maintain tooling to ensure optimal bending results.

- Regularly calibrate and maintain equipment to ensure accuracy and safety.

2. Material Handling and Preparation

Angle benders prepare and handle metal sheets, ensuring seamless bending operations.

- Inspect materials for defects, damage, or inconsistencies.

- Measure and mark materials accurately for bending.

- Load and unload metal sheets onto the bending machine efficiently.

3. Quality Control and Inspection

Angle benders ensure the quality of finished products by conducting thorough inspections.

- Inspect bent materials for dimensional accuracy, surface finish, and conformity to specifications.

- Use measuring tools and gauges to verify angles, radii, and other dimensions.

- Report any defects or deviations from standards to supervisors or quality control personnel.

4. Safety and Maintenance

Angle benders prioritize safety and maintain a clean and organized work environment.

- Adhere to safety protocols and wear appropriate personal protective equipment.

- Maintain a clean and well-organized work area to prevent accidents and optimize productivity.

- Report any equipment malfunctions or safety hazards promptly.

Interview Tips for Angle Benders

To ace an angle bender interview, candidates should thoroughly prepare and present themselves confidently. Here are some tips:

1. Research the Company and Position

Before the interview, research the company’s background, industry, and specific requirements for the angle bender position. Understanding the company’s needs and aligning your skills and experience will demonstrate your interest and preparedness.

2. Highlight Technical Skills and Experience

During the interview, emphasize your technical skills in metal bending, machine operation, and quality control. Provide specific examples of projects where you demonstrated proficiency in these areas. Quantifying your accomplishments with metrics will add credibility to your claims.

3. Showcase Safety and Quality Mindset

Angle bending requires a strong emphasis on safety and quality. Convey your commitment to following safety protocols and maintaining a clean and organized work environment. Highlight your experience in identifying and resolving quality issues, ensuring that products meet specifications.

4. Practice Common Interview Questions

Prepare for common interview questions such as “Tell me about your experience in angle bending” or “How do you handle complex bending challenges?” Practice your answers to articulate your skills, experience, and problem-solving abilities effectively.

5. Ask Thoughtful Questions

At the end of the interview, asking thoughtful questions about the company, the position, or the industry demonstrates your interest and engagement. It also gives you an opportunity to clarify any uncertainties and assess if the role is a suitable fit for your career aspirations.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Angle Bender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Angle Bender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.