Feeling lost in a sea of interview questions? Landed that dream interview for Angle Shearer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Angle Shearer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

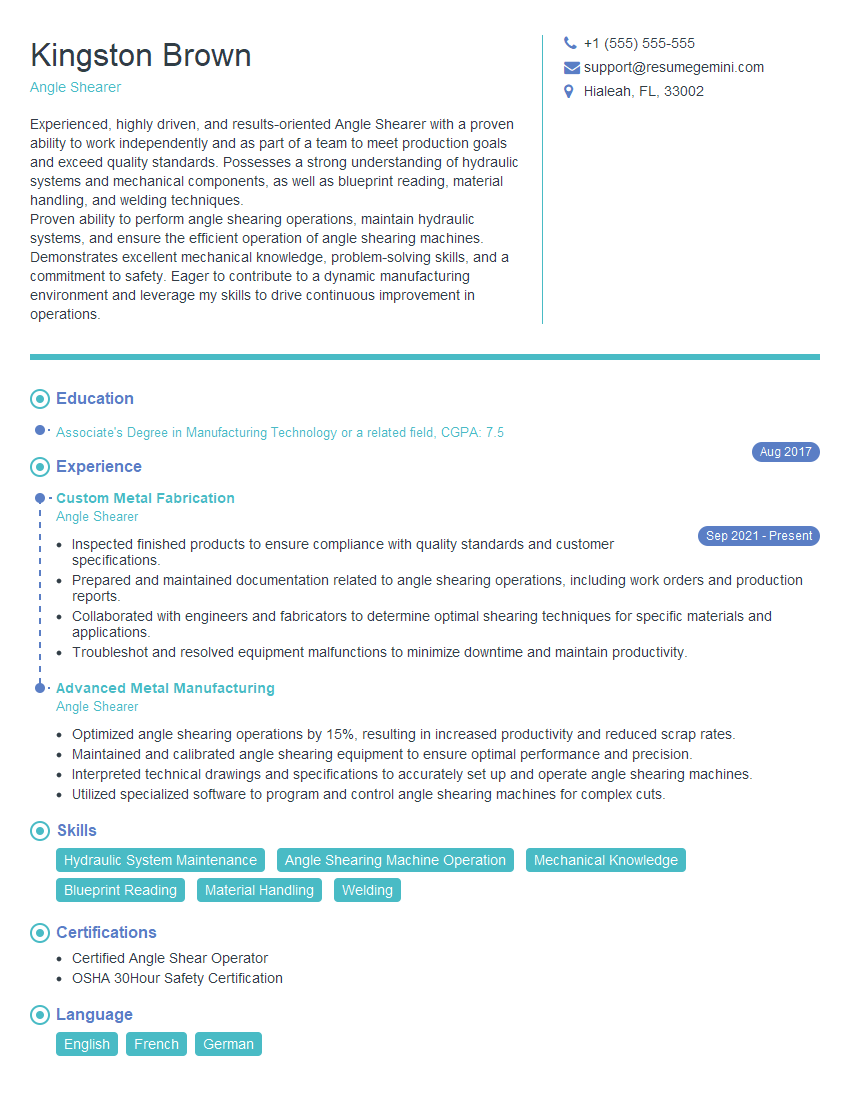

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Angle Shearer

1. What are the key challenges you foresee in the role of Angle Shearer?

The role of Angle Shearer is highly technical and requires expertise in a range of areas. Some of the key challenges I foresee in this role are:

- Staying up-to-date on the latest technology and techniques.

- Working with a variety of materials and equipment.

- Meeting the demands of a fast-paced environment.

- Working as part of a team to achieve common goals.

- Communicating effectively with colleagues, customers, and other stakeholders.

2. How would you go about ensuring the accuracy and quality of your work as an Angle Shearer?

Accuracy

- Use precise measuring tools and equipment.

- Follow established procedures and standards.

- Double-check measurements and calculations.

- Seek feedback from colleagues and supervisors.

Quality

- Use high-quality materials and equipment.

- Take pride in your work and strive for excellence.

- Continuously improve your skills and knowledge.

- Meet or exceed customer expectations.

3. What are the common safety hazards associated with the role of Angle Shearer, and how would you mitigate them?

As an Angle Shearer, I would be aware of the following common safety hazards and take the following steps to mitigate them:

- Cuts and lacerations: Wear appropriate protective clothing, use sharp tools properly, and be aware of your surroundings.

- Eye injuries: Wear safety glasses or goggles when operating equipment.

- Repetitive motion injuries: Take breaks throughout the day and use ergonomic tools to reduce strain on muscles and joints.

- Slips, trips, and falls: Keep the work area clean and organized, wear appropriate footwear, and be aware of potential hazards.

- Electrical hazards: Follow electrical safety guidelines, use proper equipment, and never work on live wires.

4. What types of equipment and techniques are used in Angle Shearing, and how do you stay updated on the latest advancements?

- Angle shears: Machines that cut metal at specific angles.

- Press brakes: Machines that bend metal into desired shapes.

- Guillotine shears: Machines that cut metal using a blade that falls vertically.

- Plasma cutters: Machines that cut metal using a plasma arc.

- Laser cutters: Machines that cut metal using a laser beam.

To stay updated on the latest advancements, I read industry publications, attend trade shows, and participate in online forums.

5. How do you prioritize tasks and manage your time effectively, especially when working under tight deadlines?

- Create a to-do list and prioritize tasks based on importance and urgency.

- Break down large tasks into smaller, more manageable ones.

- Delegate tasks to others when possible.

- Take breaks throughout the day to avoid burnout.

- Use time management tools and techniques.

6. How do you handle working independently and as part of a team?

Working independently

- Take initiative and be self-motivated.

- Be organized and efficient.

- Be able to work without constant supervision.

Working as part of a team

- Be a good communicator and listener.

- Be cooperative and willing to help others.

- Be able to compromise and work towards a common goal.

7. How do you approach learning new skills and technologies?

- Read books and articles.

- Attend workshops and training courses.

- Watch online tutorials.

- Experiment with new techniques.

- Ask for help from colleagues and supervisors.

8. How do you measure and maintain the quality of your work?

- Set clear standards and expectations.

- Use inspection tools and techniques to check the quality of your work.

- Get feedback from customers and colleagues.

- Continuously improve your skills and knowledge.

- Maintain a quality control record.

9. What is your experience with different types of metalworking equipment?

- Angle shears

- Press brakes

- Guillotine shears

- Plasma cutters

- Laser cutters

- Welding equipment

- Grinders

- Drill presses

- Lathes

- Mills

10. What are your career goals and how does this role align with them?

My career goal is to become a highly skilled and experienced Angle Shearer. I believe that this role will provide me with the opportunity to develop my skills, gain valuable experience, and contribute to the success of the company. I am eager to learn from experienced professionals, work on challenging projects, and make a positive impact on the industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Angle Shearer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Angle Shearer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Angle Shearers are responsible for operating angle shearing machines to cut metal sheets into specific shapes and sizes. They play a crucial role in the fabrication of metal components for various industries, including construction, automotive, and electronics. Key responsibilities of an Angle Shearer include:

1. Machine Operation and Setup

Setting up and operating angle shearing machines, ensuring accurate and precise cuts.

- Adjusting blade clearances, angles, and feed rates to meet specifications.

- Loading and positioning metal sheets onto the machine for shearing.

2. Quality Control

Inspecting and measuring cut pieces to ensure they meet dimensional tolerances and quality standards.

- Using measuring tools such as calipers, micrometers, and rulers to verify accuracy.

- Identifying and correcting any deviations from specified requirements.

3. Material Handling

Handling and moving metal sheets, including loading, unloading, and stacking.

- Using material handling equipment such as forklifts or hoists to safely move heavy sheets.

- Ensuring proper storage and organization of materials.

4. Machine Maintenance

Performing basic machine maintenance and troubleshooting to ensure optimal performance.

- Cleaning and lubricating machine components.

- Identifying and reporting any mechanical issues or malfunctions.

Interview Tips

To ace an interview for an Angle Shearer position, candidates should thoroughly prepare by researching the role, practicing their answers, and presenting themselves professionally.

1. Research the Company and Role

Familiarize yourself with the company’s industry, products or services, and the specific requirements of the Angle Shearer position.

- Visit the company website to gather information about their business and operations.

- Review the job description and identify the key skills and responsibilities.

2. Prepare Your Answers

Anticipate common interview questions and prepare well-thought-out answers that highlight your relevant skills and experience.

- Example Outline:

- Question: Tell us about your experience operating an angle shearing machine.

- Answer: “In my previous role, I was responsible for operating an angle shearing machine in a high-volume metal fabrication shop. I consistently met production targets while maintaining high quality standards. I am proficient in setting up and adjusting the machine to produce precise cuts in various thicknesses and materials.”

3. Emphasize Quality and Precision

Angle Shearers are responsible for ensuring the accuracy and quality of cut metal pieces. Highlight your attention to detail and commitment to meeting precise specifications.

- Provide examples of how you have maintained high quality standards in your previous work experience.

- Explain your understanding of quality control procedures and how you implement them in your work.

4. Demonstrate Safety Awareness

Angle shearing machines can be hazardous if operated improperly. Emphasize your safety consciousness and adherence to safety protocols.

- Discuss your knowledge of safety precautions and regulations related to angle shearing operations.

- Share examples of how you have enforced safety measures in a work environment.

Next Step:

Now that you’re armed with the knowledge of Angle Shearer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Angle Shearer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini