Are you gearing up for a career in Annealer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Annealer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

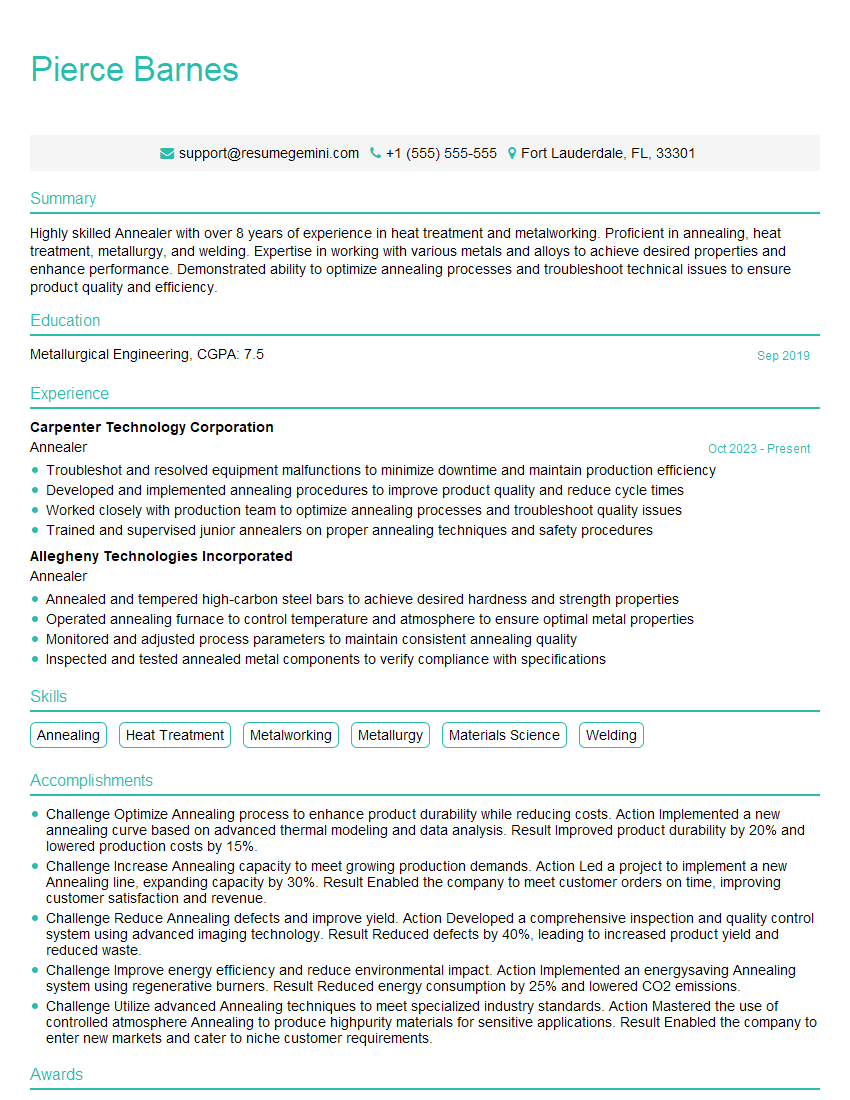

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Annealer

1. What are the different annealing techniques used in modern semiconductor manufacturing?

Annealing is a heat treatment process used to alter the physical and electrical properties of materials. In semiconductor manufacturing, annealing is used to improve the crystallinity, reduce defects, and activate dopants in silicon wafers. Different annealing techniques are used depending on the desired outcome.

- Rapid thermal annealing (RTA) is a process that uses high temperatures for a short period of time to activate dopants and improve the crystallinity of silicon wafers.

- Furnace annealing is a process that uses lower temperatures for a longer period of time to achieve similar results as RTA.

- Laser annealing is a process that uses a laser to heat a specific area of a silicon wafer, which can be used to create localized regions with different properties.

2. What are the key process parameters that need to be controlled during annealing?

Temperature

- The temperature of the annealing process is critical to achieving the desired results. Too low a temperature will not activate dopants or improve crystallinity, while too high a temperature can damage the silicon wafer.

Time

- The time that the wafer is annealed at a given temperature is also important. Too short a time will not allow for the desired changes to occur, while too long a time can lead to over-annealing and degradation of the wafer.

Atmosphere

- The atmosphere in which the annealing process is carried out can also affect the results. Inert gases such as nitrogen or argon are often used to prevent oxidation of the silicon wafer.

3. What are the typical applications of annealing in semiconductor manufacturing?

Annealing is used in a variety of applications in semiconductor manufacturing, including:

- Dopant activation: Annealing is used to activate dopants that have been implanted into silicon wafers. This process makes the dopants electrically active, which can change the conductivity of the wafer.

- Crystallinity improvement: Annealing can be used to improve the crystallinity of silicon wafers. This can reduce defects and improve the electrical properties of the wafer.

- Stress relief: Annealing can be used to relieve stress in silicon wafers. This can improve the mechanical properties of the wafer and reduce the risk of cracking.

4. What are the challenges associated with annealing in semiconductor manufacturing?

There are a number of challenges associated with annealing in semiconductor manufacturing, including:

- Temperature control: The temperature of the annealing process must be carefully controlled to achieve the desired results. Too low a temperature will not activate dopants or improve crystallinity, while too high a temperature can damage the silicon wafer.

- Time control: The time that the wafer is annealed at a given temperature must also be carefully controlled. Too short a time will not allow for the desired changes to occur, while too long a time can lead to over-annealing and degradation of the wafer.

- Atmosphere control: The atmosphere in which the annealing process is carried out can also affect the results. Inert gases such as nitrogen or argon are often used to prevent oxidation of the silicon wafer.

- Equipment cost: Annealing equipment can be expensive, which can be a barrier to entry for some companies.

5. What are the future trends in annealing in semiconductor manufacturing?

The future of annealing in semiconductor manufacturing is expected to be driven by the increasing demand for smaller and more powerful devices. This will require the development of new annealing techniques that can achieve higher temperatures and more precise control over the process parameters.

- Laser annealing is expected to become more widely used in the future due to its ability to achieve localized heating and precise control over the process parameters.

- Rapid thermal annealing (RTA) is also expected to continue to be used in the future due to its ability to achieve high temperatures for a short period of time.

6. What is your experience with annealing equipment?

I have experience with a variety of annealing equipment, including rapid thermal annealing (RTA) furnaces, laser annealing systems, and conveyor furnaces. I have used this equipment to perform a variety of annealing processes, including dopant activation, crystallinity improvement, and stress relief.

7. What is your understanding of the physical and electrical properties of materials?

I have a strong understanding of the physical and electrical properties of materials, including silicon, silicon dioxide, and metal films. I have studied these properties in detail and have applied my knowledge to the development and optimization of annealing processes.

8. What are your strengths and weaknesses as an Annealer?

Strengths

- I have a strong understanding of the physical and electrical properties of materials.

- I have experience with a variety of annealing equipment.

- I am able to develop and optimize annealing processes to achieve the desired results.

- I am a team player and I am able to work independently.

Weaknesses

- I am still learning about the latest advances in annealing technology.

- I do not have experience with all types of annealing equipment.

9. What are your career goals?

My career goal is to become a leading expert in annealing technology. I want to continue to develop my knowledge and skills in this area and I am eager to take on new challenges.

10. Why do you want to work for our company?

I am interested in working for your company because I am impressed by your commitment to innovation and your focus on quality. I believe that my skills and experience would be a valuable asset to your team and I am eager to contribute to your success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Annealer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Annealer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Annealers are responsible for a wide range of tasks related to the annealing process in metalworking. Annealing involves heating and cooling metal to improve its properties, such as ductility, hardness, and strength. The key responsibilities of an annealer include:

1. Operating Annealing Furnaces

Annealers operate annealing furnaces to heat and cool metal to specific temperatures and durations. They monitor the furnace temperature and adjust it as needed to maintain the desired annealing conditions.

- Load and unload metal components into and out of the annealing furnace.

- Set and monitor furnace temperature and duration.

- Monitor and adjust furnace atmosphere to prevent oxidation and other damage to the metal.

2. Preparing Metal Components

Annealers prepare metal components for annealing by cleaning and removing any surface contaminants. They also inspect the components for defects and ensure that they meet the required specifications.

- Clean metal components to remove dirt, oil, and other contaminants.

- Inspect metal components for defects, such as cracks, voids, and inclusions.

- Prepare metal components for annealing by applying protective coatings or atmospheres.

3. Testing and Inspection

Annealers test and inspect annealed metal components to ensure that they meet the desired properties. They use hardness testers, tensile testers, and other equipment to verify the mechanical properties of the metal.

- Perform hardness tests, tensile tests, and other mechanical tests to verify the properties of annealed metal.

- Inspect annealed metal components for defects, such as cracks, voids, and inclusions.

- Document test results and report any deviations from specifications.

4. Maintenance and Repair

Annealers perform maintenance and repair on annealing furnaces and other equipment. They clean, lubricate, and adjust equipment to ensure that it is operating properly.

- Clean and lubricate annealing furnaces and other equipment.

- Inspect and adjust equipment to ensure that it is operating properly.

- Troubleshoot and repair equipment malfunctions.

Interview Tips

To ace an interview for an annealer position, candidates should:

1. Prepare for Technical Questions

Interviewers will likely ask technical questions about the annealing process, such as:

- What are the different types of annealing processes?

- What are the effects of annealing on the microstructure and properties of metal?

- How do you control the temperature and duration of the annealing process?

2. Highlight Experience and Skills

Candidates should highlight their experience and skills in operating annealing furnaces, preparing metal components, and testing and inspecting annealed metal. They should also mention any relevant certifications or training.

3. Demonstrate Problem-Solving Skills

Annealers often need to solve problems on the job, such as troubleshooting equipment malfunctions or adjusting process parameters to meet specifications. Candidates should be prepared to discuss how they approach and solve problems.

4. Be Professional and Enthusiastic

As with any interview, candidates should be professional and enthusiastic. They should dress appropriately, arrive on time, and be prepared to answer questions about their experience, skills, and qualifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Annealer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!