Are you gearing up for an interview for a Annealing Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Annealing Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

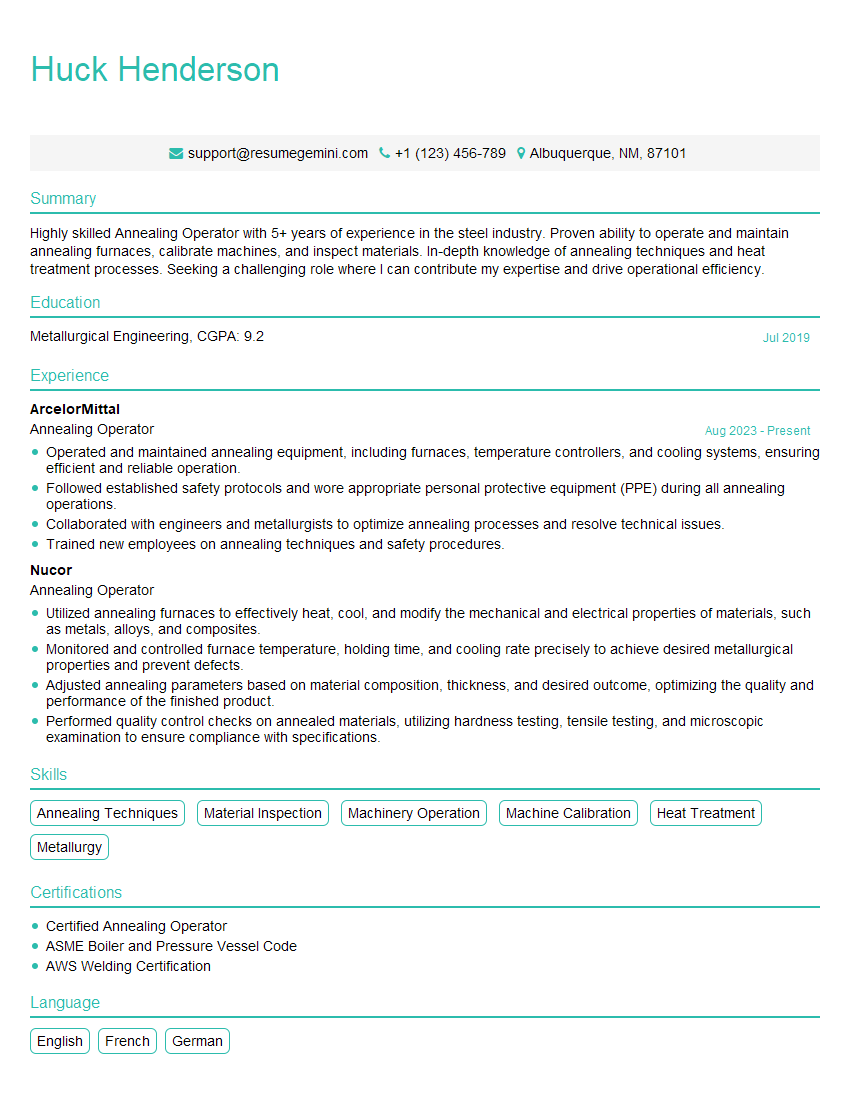

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Annealing Operator

1. What are the different types of annealing processes and their applications?

- Stress Relief Annealing: This process is used to remove internal stresses from metal components by heating the metal to a high temperature and then cooling it slowly.

- Soft Annealing: This process is used to soften metals by heating them to a high temperature and then cooling them slowly in a controlled atmosphere.

- Normalizing: This process is used to refine the grain structure of metals by heating them to a high temperature and then cooling them in air.

- Hardening and Tempering: This process is used to increase the hardness and strength of metals by heating them to a high temperature and then quenching them in a liquid medium, such as oil or water.

- Austempering: This process is used to produce a martensitic structure in steel by heating it to a high temperature and then quenching it in a molten salt bath.

2. What are the key parameters to consider when optimizing an annealing process?

Time

- The time at temperature affects the degree of annealing.

- Longer times lead to more complete annealing.

Temperature

- The temperature must be high enough to allow for the desired changes in the material’s microstructure.

- However, temperatures that are too high can cause grain growth or other undesirable effects.

Cooling Rate

- The cooling rate affects the final properties of the annealed material.

- Rapid cooling rates can result in a harder material, while slower cooling rates can result in a softer material.

Atmosphere

- The atmosphere in the annealing furnace can affect the surface properties of the annealed material.

- For example, an oxidizing atmosphere can lead to the formation of a scale on the surface of the material.

3. What are the common defects that can occur during annealing and how can they be prevented?

- Warping: This can be prevented by using fixtures to support the parts during annealing.

- Scaling: This can be prevented by using a protective atmosphere in the annealing furnace.

- Decarburization: This can be prevented by using a carburizing atmosphere in the annealing furnace.

- Grain growth: This can be prevented by using a rapid cooling rate after annealing.

- Cracking: This can be prevented by using a stress relieving anneal before the final annealing process.

4. What are the safety precautions that must be taken when operating an annealing furnace?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Be aware of the hazards of the materials being annealed.

- Ensure that the furnace is properly ventilated.

- Do not open the furnace door until the parts have cooled.

- Follow all operating instructions for the annealing furnace.

5. How do you troubleshoot common problems that can occur during annealing?

- If the parts are not annealing properly, check the temperature, time, and cooling rate.

- If the parts are warping, check the fixtures and make sure that they are supporting the parts properly.

- If the parts are scaling, check the atmosphere in the furnace and make sure that it is protective.

- If the parts are decarburizing, check the atmosphere in the furnace and make sure that it is carburizing.

- If the parts are cracking, check the stress relieving anneal and make sure that it is being done properly.

6. What are the different types of annealing furnaces and their advantages and disadvantages?

- Batch furnaces: These furnaces are used to anneal small batches of parts.

- Continuous furnaces: These furnaces are used to anneal large volumes of parts.

- Vacuum furnaces: These furnaces are used to anneal parts in a vacuum environment.

- Controlled atmosphere furnaces: These furnaces are used to anneal parts in a controlled atmosphere.

7. What is the difference between annealing and tempering?

- Annealing is a process that is used to soften a metal by heating it to a high temperature and then cooling it slowly.

- Tempering is a process that is used to increase the hardness and strength of a metal by heating it to a high temperature and then cooling it quickly.

8. What are the different types of materials that can be annealed?

- Ferrous metals: These metals contain iron and are the most common type of metals that are annealed.

- Non-ferrous metals: These metals do not contain iron and can also be annealed.

- Alloys: Alloys are mixtures of two or more metals and can also be annealed.

9. What are the benefits of annealing?

- Annealing can improve the ductility of a metal.

- Annealing can reduce the hardness of a metal.

- Annealing can relieve internal stresses in a metal.

- Annealing can improve the machinability of a metal.

- Annealing can improve the formability of a metal.

10. What are the disadvantages of annealing?

- Annealing can be a time-consuming process.

- Annealing can be expensive.

- Annealing can cause a metal to lose strength.

- Annealing can cause a metal to become more brittle.

- Annealing can cause a metal to change color.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Annealing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Annealing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Annealing Operator plays a critical role in the manufacturing process by operating and monitoring annealing furnaces. Following are the key responsibilities associated with the job:

1. Furnace Operation and Monitoring

Responsible for operating and monitoring annealing furnaces to ensure proper and safe functioning.

- Control and maintain furnace temperature, atmosphere, and gas flow

- Monitor gauges, alarms, and readouts to ensure proper operating conditions

- Calibrate and troubleshoot furnace systems

2. Product Handling

Efficiently load, unload, and handle materials in and out of annealing furnaces.

- Follow established procedures for material handling and storage

- Use appropriate equipment, such as cranes or forklifts, to move materials

3. Quality Control

Ensure the quality of annealed products by visually inspecting and testing.

- Inspect annealed materials for defects, such as cracks, warpage, or discoloration

- Perform hardness or other quality tests as required

- Maintain and organize quality control records

4. Maintenance and Safety

Contribute to a safe and well-maintained work environment through regular maintenance and adherence to safety protocols.

- Perform routine maintenance on annealing furnaces and related equipment

- Inspect and maintain safety equipment, such as fire extinguishers and personal protective gear

- Follow all safety regulations and protocols

Interview Tips

To ace the interview for an Annealing Operator position, it’s important to highlight your relevant skills and experience while demonstrating your understanding of the job responsibilities. Here are some interview preparation tips and hacks to consider:

1. Research the Company and Industry

Take the time to thoroughly research the company you’re applying to, including their products, services, and industry standing. Understanding the company’s operations and the role of annealing in their processes will demonstrate your interest and preparation.

2. Practice Your Communication Skills

Effective communication is essential for an Annealing Operator. Practice clearly and concisely articulating your thoughts, both in technical and non-technical terms. You may be asked to explain technical concepts or procedures to non-technical professionals.

3. Highlight Your Technical Expertise

Showcase your knowledge of annealing processes, furnace operation, and quality control measures. Emphasize your ability to calibrate, troubleshoot, and maintain annealing furnaces. Providing specific examples of your technical skills will strengthen your application.

4. Emphasize Safety Consciousness

Safety is paramount in the manufacturing industry. Highlight your commitment to safety by emphasizing your adherence to protocols and your experience in maintaining a safe work environment. Mention any safety certifications or training you have obtained.

5. Be Prepared to Discuss Your Experience

During the interview, be prepared to discuss your previous experience as an Annealing Operator. Provide specific examples of your responsibilities, accomplishments, and any challenges you have faced. Quantify your results whenever possible to demonstrate the impact of your work.

6. Ask Thoughtful Questions

Asking insightful questions at the end of the interview shows that you’re engaged and interested in the position. Prepare a few questions about the company, the specific role, or the industry. This will not only help you gather more information but also demonstrate your enthusiasm for the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Annealing Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Annealing Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.