Feeling lost in a sea of interview questions? Landed that dream interview for Annealing Torch Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Annealing Torch Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

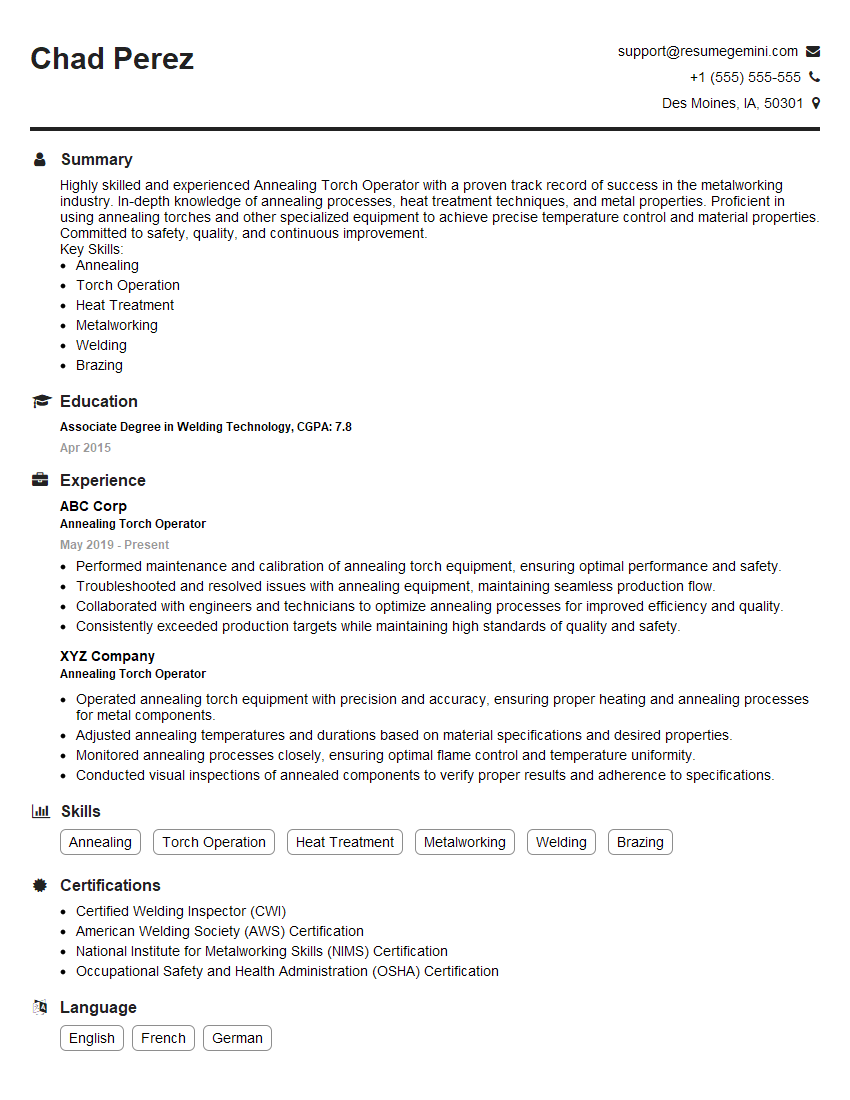

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Annealing Torch Operator

1. Explain the key responsibilities of an Annealing Torch Operator?

As an Annealing Torch Operator, my primary responsibilities include:

- Operating and maintaining annealing torches to heat treat metal components to achieve desired properties.

- Monitoring temperature and time parameters to ensure proper annealing cycles.

- Inspecting and verifying the quality of annealed parts to meet specifications.

- Maintaining a clean and organized work area, adhering to safety regulations

2. Describe the different types of annealing techniques and their applications?

Flame Annealing

- Uses an open flame to heat the metal.

- Suitable for surface hardening and stress relief.

Induction Annealing

- Generates heat using electromagnetic induction.

- Provides precise and localized heating for selective hardening.

Furnace Annealing

- Involves placing the metal in a heated furnace.

- Used for bulk annealing and achieving uniform properties.

3. What is the importance of temperature control during annealing?

Temperature control is crucial during annealing to:

- Achieve desired metallurgical properties by altering the microstructure.

- Prevent overheating or underheating, which can impair the material’s performance.

- Ensure consistency and repeatability in the annealing process.

4. How do you ensure the safety and quality of annealed parts?

I prioritize safety by:

- Wearing appropriate personal protective equipment (PPE).

- Following established safety protocols and procedures.

- Maintaining a well-ventilated workspace to minimize fumes.

To ensure quality, I:

- Inspect parts visually and dimensionally to verify conformance to specifications.

- Use non-destructive testing methods, such as hardness testing, to assess the material’s properties.

- Document and record all inspection and testing results for traceability.

5. What troubleshooting techniques do you use when facing issues with annealing?

Common issues and troubleshooting techniques include:

- Overheating: Adjust temperature settings, reduce heating time, or consider using a different annealing method.

- Underheating: Increase temperature or heating time, or check the accuracy of temperature measurement devices.

- Non-uniform heating: Inspect the annealing torch, adjust the flame angle or distribution, or consider using a different heating technique.

- Contamination: Clean the metal surface before annealing, use protective coatings, or investigate potential sources of contamination.

6. How do you stay up-to-date with advancements in annealing technologies?

I maintain my knowledge and skills by:

- Attending industry seminars and workshops.

- Reading technical articles and research papers.

- Participating in online forums and discussion groups.

- Seeking guidance and mentorship from experienced professionals.

7. What is the difference between annealing and tempering?

- Annealing: A process that involves heating and slowly cooling a metal to soften it, reduce brittleness, and improve ductility.

- Tempering: A subsequent heat treatment that follows annealing, where the metal is heated to a lower temperature and held for a specific duration to enhance strength and hardness.

8. What factors influence the selection of annealing parameters?

- Material properties: Composition, grain structure, and initial hardness.

- Desired results: Required hardness, strength, and ductility.

- Equipment capabilities: Type of annealing torch, temperature range, and heating rate.

- Production requirements: Batch size, turnaround time, and cost considerations.

9. Explain the role of carburizing in the annealing process?

Carburizing is a process that introduces carbon into the surface of the metal during annealing:

- Increases surface hardness and wear resistance.

- Improves fatigue strength and toughness.

- Can be achieved through various techniques, such as pack carburizing or gas carburizing.

10. How do you optimize the annealing process for different metals?

- Steel: Adjust temperature and cooling rate to achieve desired microstructure and mechanical properties.

- Aluminum: Use rapid heating and cooling to prevent grain growth and maintain strength.

- Copper: Anneal at low temperatures to improve ductility and conductivity.

- Titanium: Control annealing parameters carefully to avoid embrittlement and preserve the material’s unique properties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Annealing Torch Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Annealing Torch Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Annealing Torch Operators are responsible for using an annealing torch to heat and cool metal parts in order to change their properties. They work in a variety of industries, including automotive, aerospace, and manufacturing.

1. Operate annealing torch

Annealing torch operators must be proficient in operating an annealing torch. This involves understanding how to adjust the flame, temperature, and speed of the torch to achieve the desired results.

- Adjust the flame to achieve the correct temperature and size

- Move the torch at a consistent speed to ensure even heating

- Monitor the temperature of the metal using a pyrometer

2. Heat metal parts

Annealing torch operators use the torch to heat metal parts to a specific temperature. This temperature is typically between 1,000 and 2,000 degrees Fahrenheit (538-1093 degrees Celsius).

- Place the metal part in a fixture

- Heat the metal part until it reaches the desired temperature

- Monitor the temperature of the metal using a pyrometer

3. Cool metal parts

After the metal part has been heated, the annealing torch operator must cool it. This is typically done by quenching the part in water or oil. The rate of cooling must be controlled to avoid cracking the metal.

- Quench the metal part in water or oil

- Control the rate of cooling to avoid cracking the metal

- Monitor the temperature of the metal using a pyrometer

4. Inspect metal parts

After the metal part has been annealed, the annealing torch operator must inspect it for defects. This includes checking for cracks, voids, and other imperfections.

- Visually inspect the metal part for defects

- Use a microscope to inspect the metal part for hidden defects

- Document any defects that are found

Interview Tips

Preparing for an Annealing Torch Operator interview can be a daunting task, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you to tailor your answers to the specific requirements of the position.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company, if possible

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions

- Practice your answers out loud

- Get feedback from a friend or family member

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as being late can reflect poorly on you.

- Wear a suit or business casual attire

- Be punctual for your interview

- Make eye contact and smile when you meet the interviewer

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the position. Be sure to highlight your skills and experience, and be confident in your abilities.

- Be positive and enthusiastic throughout the interview

- Highlight your skills and experience

- Be confident in your abilities

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Annealing Torch Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!