Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Anode Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

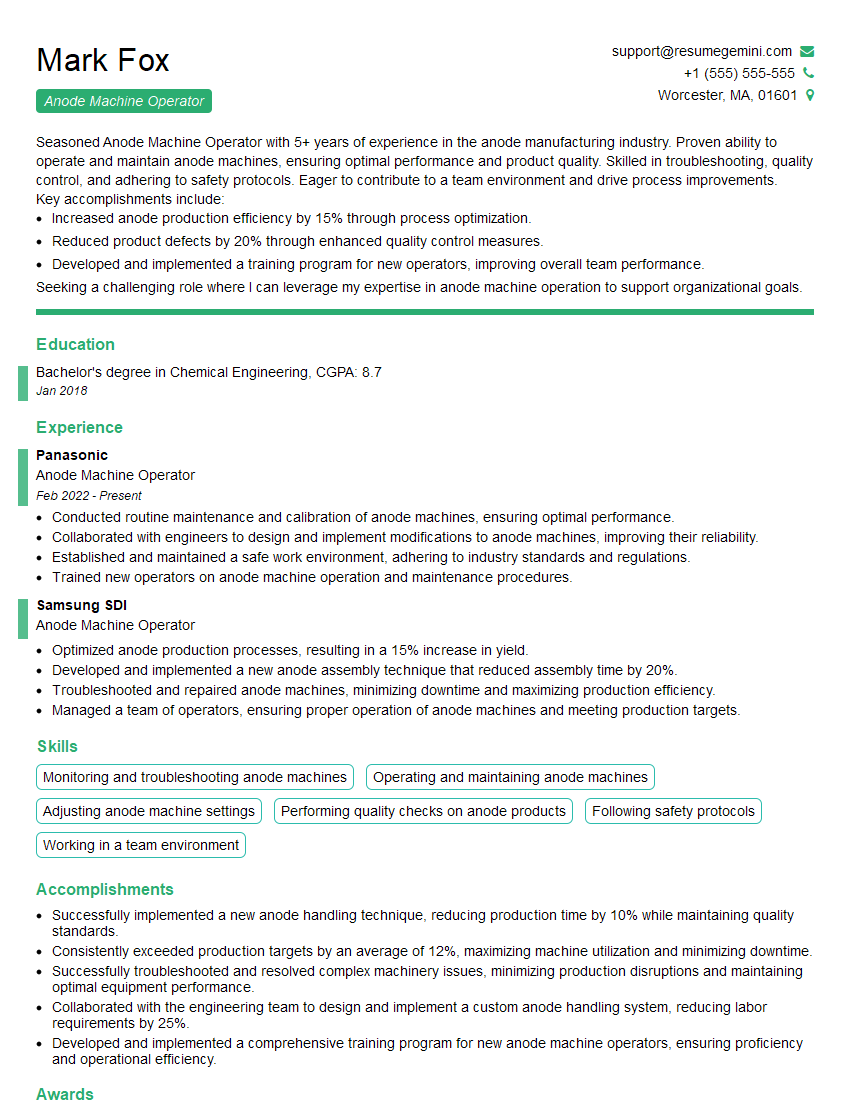

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Anode Machine Operator

1. Explain the process of anode preparation?

The process of anode preparation is to prepare the anode for use in the electrolysis cell. It involves the following steps:

- Cleaning the anode to remove any surface contaminants that would interfere with the electrolysis process.

- Applying a conductive coating to the anode to improve electrical conductivity.

- Activating the anode by passing an electric current through it to form a thin oxide layer on the surface. This oxide layer increases the anode’s catalytic activity.

2. What are the key parameters that need to be controlled during anode operation?

Temperature control

- The temperature of the anode is critical to its performance.

- Too high a temperature can damage the anode and reduce its lifespan.

- Too low a temperature can reduce the anode’s efficiency.

Current density

- The current density is the amount of current flowing through the anode per unit area.

- A high current density can lead to the formation of hot spots on the anode.

- A low current density can reduce the anode’s efficiency.

Electrolyte concentration

- The electrolyte concentration is the amount of electrolyte dissolved in the solvent.

- Too high an electrolyte concentration can lead to the formation of dendrites on the anode.

- Too low an electrolyte concentration can reduce the anode’s efficiency.

3. What are the common problems that can occur during anode operation and how can they be prevented?

- Anode passivation: This is a condition in which the anode surface becomes coated with a non-conductive layer of oxide or other compounds, which reduces its efficiency. It can be prevented by using a suitable anode material and by controlling the operating conditions.

- Anode corrosion: This is a condition in which the anode is attacked by the electrolyte, which can lead to its failure. It can be prevented by using a suitable anode material and by controlling the electrolyte concentration.

- Anode hot spots: These are areas on the anode where the current density is too high, which can lead to overheating and damage. They can be prevented by controlling the current density and by providing adequate cooling.

4. What are the safety precautions that need to be taken when operating an anode machine?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Ensure that the anode machine is properly grounded.

- Do not touch the anode or the electrolyte with bare hands.

- Be aware of the potential for electrical shock and take precautions to avoid it.

- Follow all operating instructions carefully.

5. What are the maintenance procedures that need to be carried out on an anode machine?

- Regularly inspect the anode for signs of wear or damage.

- Clean the anode and the electrolyte tank as needed.

- Check the electrical connections and make sure they are tight.

- Calibrate the anode machine according to the manufacturer’s instructions.

- Follow all maintenance instructions carefully.

6. What are the troubleshooting procedures for an anode machine?

- If the anode is not producing the desired results, check the following:

- The anode is properly prepared and activated.

- The operating parameters are within the specified range.

- The electrolyte is fresh and at the correct concentration.

- If the anode is overheating, check the following:

- The current density is not too high.

- The anode is properly cooled.

- If the anode is corroding, check the following:

- The anode material is compatible with the electrolyte.

- The electrolyte concentration is not too high.

7. What are the different types of anode materials that can be used?

- Carbon

- Graphite

- Metal oxides

- Semiconductors

- Conducting polymers

8. What are the factors that affect the efficiency of an anode?

- The anode material

- The anode size

- The anode shape

- The operating temperature

- The electrolyte concentration

- The current density

9. What are the applications of anode machines?

- Electroplating

- Anodizing

- Electrolysis

- Fuel cells

- Batteries

10. What are the future trends in anode technology?

- The development of new anode materials with higher efficiency and longer lifespan.

- The development of new anode designs that improve performance and reduce costs.

- The integration of anode machines with other technologies, such as renewable energy sources.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Anode Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Anode Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Anode Machine Operator is responsible for the operation, monitoring, and maintenance of anode machines used in the production of aluminum, copper, and other non-ferrous metals.

1. Machine Operation

Operate and monitor anode machines to ensure efficient production of anodes.

- Control machine settings, such as temperature, pressure, and speed.

- Monitor equipment for signs of wear or malfunction.

2. Material Handling

Handle and load raw materials, such as carbon and petroleum coke, into the anode machines.

- Unload finished anodes from the machines.

- Maintain a clean and organized work area.

3. Maintenance

Perform routine maintenance and repairs on anode machines, including:

- Inspecting and replacing worn parts.

- Lubricating and adjusting equipment.

4. Safety

Follow safety procedures and regulations to ensure a safe work environment.

- Wear appropriate personal protective equipment.

- Identify and control potential hazards.

Interview Tips

Preparing for an interview for an Anode Machine Operator position requires thorough research and practice. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s values, mission, and core business. Learn about the aluminum or copper industry and its production processes.

2. Highlight Relevant Experience

Emphasize your experience in operating anode machines or similar equipment. Quantify your accomplishments and use specific examples to demonstrate your skills.

3. Demonstrate Technical Knowledge

Be prepared to answer questions about anode machine operation, maintenance, and safety. Show your understanding of the anode production process and the importance of quality control.

4. Emphasize Safety Consciousness

Discuss your commitment to safety and your familiarity with safety regulations and procedures. Highlight your ability to identify and mitigate workplace hazards.

5. Practice Common Interview Questions

Prepare for common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?” Practice your answers to ensure they are concise, relevant, and engaging.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Anode Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.