Feeling lost in a sea of interview questions? Landed that dream interview for Anodic Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Anodic Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

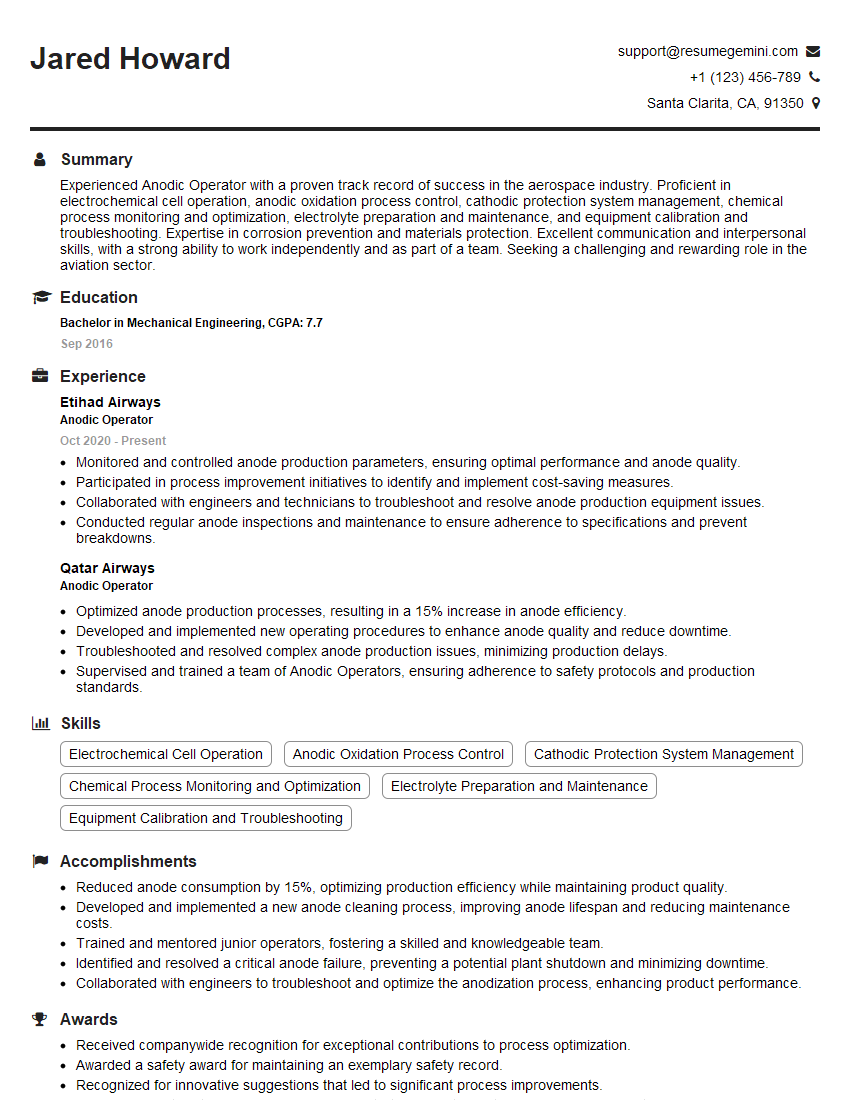

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Anodic Operator

1. What is the purpose of anodic oxidation?

Anodic oxidation is an electrochemical process that converts the surface of a metal into a protective oxide layer. This layer protects the metal from corrosion, wear, and other environmental factors.

2. What are the different types of anodic oxidation?

Chromic acid anodizing

- This is the most common type of anodic oxidation, and it is used on aluminum alloys.

- The process involves immersing the metal in a chromic acid solution and passing an electric current through it.

- The result is a hard, wear-resistant oxide layer that is resistant to corrosion.

Sulfuric acid anodizing

- This type of anodic oxidation is used on magnesium alloys.

- The process involves immersing the metal in a sulfuric acid solution and passing an electric current through it.

- The result is a soft, porous oxide layer that is resistant to corrosion.

Hard anodizing

- This type of anodic oxidation is used on aluminum alloys, and it produces a very hard, wear-resistant oxide layer.

- The process involves immersing the metal in a sulfuric acid solution and passing a high electric current through it.

- The result is a oxide layer that is harder than steel.

3. What are the factors that affect the quality of the anodic oxide layer?

- The type of metal being anodized

- The electrolyte solution used

- The temperature of the electrolyte solution

- The current density

- The duration of the anodizing process

4. What are the applications of anodic oxidation?

- Automotive parts

- Aerospace components

- Medical devices

- Consumer electronics

- Architectural products

5. What are the advantages of anodic oxidation?

- Improved corrosion resistance

- Increased wear resistance

- Enhanced electrical insulation

- Improved appearance

- Increased bondability

6. What are the disadvantages of anodic oxidation?

- Can be expensive

- Can be time-consuming

- Can be difficult to control

- Can produce hazardous waste

7. What are the safety precautions that must be taken when working with anodic oxidation?

- Wear proper protective clothing and equipment, including gloves, goggles, and a respirator.

- Work in a well-ventilated area.

- Handle chemicals carefully and avoid contact with skin and eyes.

- Dispose of hazardous waste properly.

8. What are the troubleshooting tips for anodic oxidation?

- If the oxide layer is too thin, increase the current density or the duration of the anodizing process.

- If the oxide layer is too thick, decrease the current density or the duration of the anodizing process.

- If the oxide layer is not uniform, check the temperature of the electrolyte solution and the current density.

- If the oxide layer is discolored, check the purity of the electrolyte solution and the presence of contaminants.

9. What are the future trends in anodic oxidation?

- The development of new electrolytes that are more environmentally friendly.

- The development of new processes that are more efficient and cost-effective.

- The development of new applications for anodic oxidation.

10. What is your experience with anodic oxidation?

I have been working with anodic oxidation for the past 5 years. I have experience with all types of anodic oxidation, including chromic acid anodizing, sulfuric acid anodizing, and hard anodizing. I am also familiar with the safety precautions that must be taken when working with anodic oxidation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Anodic Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Anodic Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Anodic Operators play a vital role in the anodizing process, which involves electrochemically converting the metal surface of aluminum parts into a decorative, durable, and corrosion-resistant oxide finish. The key responsibilities of an Anodic Operator typically include:

1. Anodizing Process Management

Managing and operating anodizing lines, ensuring the efficient and consistent production of anodized parts.

- Monitoring anodizing tanks and adjusting process parameters (e.g., temperature, voltage, current density) to achieve desired results.

- Loading and unloading parts into and from anodizing tanks, following established procedures to prevent contamination and ensure quality.

2. Quality Control

Inspecting and testing anodized parts to ensure they meet specified quality standards and customer requirements.

- Performing visual inspections for defects, such as scratches, pits, or discoloration.

- Conducting thickness and other tests to verify the integrity and performance of the anodized finish.

3. Equipment Maintenance

Maintaining and troubleshooting anodizing equipment, ensuring optimal performance and preventing downtime.

- Cleaning and inspecting tanks, filters, and other components to maintain proper functioning.

- Performing minor repairs and adjustments to equipment, as needed.

4. Production Support

Assisting in production planning and scheduling, optimizing resource allocation and meeting production targets.

- Working with supervisors and other departments to coordinate production activities.

- Maintaining production records and documentation to ensure compliance with quality standards and traceability.

5. Health and Safety

Adhering to all safety regulations and procedures, ensuring a safe work environment for themselves and others.

- Handling and disposing of hazardous chemicals and waste materials in compliance with regulations.

- Wearing appropriate personal protective equipment (PPE) and following safe work practices.

Interview Tips

To help candidates ace their interview for an Anodic Operator position, here are some essential tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry reputation. Research the specific anodizing process and the role of an Anodic Operator within the company’s operations.

2. Practice Your Technical Skills

Review the key job responsibilities and ensure you have a strong understanding of the technical aspects of anodizing, including the process steps, quality control procedures, and equipment used.

3. Showcase Your Attention to Detail

Anodic Operators must possess excellent attention to detail and an ability to identify and correct potential issues. Highlight examples from your experience that demonstrate your precision and commitment to quality.

4. Emphasize Safety Awareness

Safety is paramount in the anodizing industry. Explain how you prioritize safety in your work, including your knowledge of chemical handling and disposal, PPE usage, and emergency procedures.

5. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Practice answering questions about your experience, technical skills, safety practices, and why you’re interested in the position.

6. Dress Professionally and Punctually

First impressions matter. Dress appropriately for the interview and arrive on time. Your professional demeanor will reflect your commitment and respect for the company.

7. Ask Questions

Prepare insightful questions to ask the interviewer about the company, the position, and the industry. This shows your engagement and enthusiasm for the opportunity.

Next Step:

Now that you’re armed with the knowledge of Anodic Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Anodic Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini