Are you gearing up for a career in Anodize Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Anodize Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

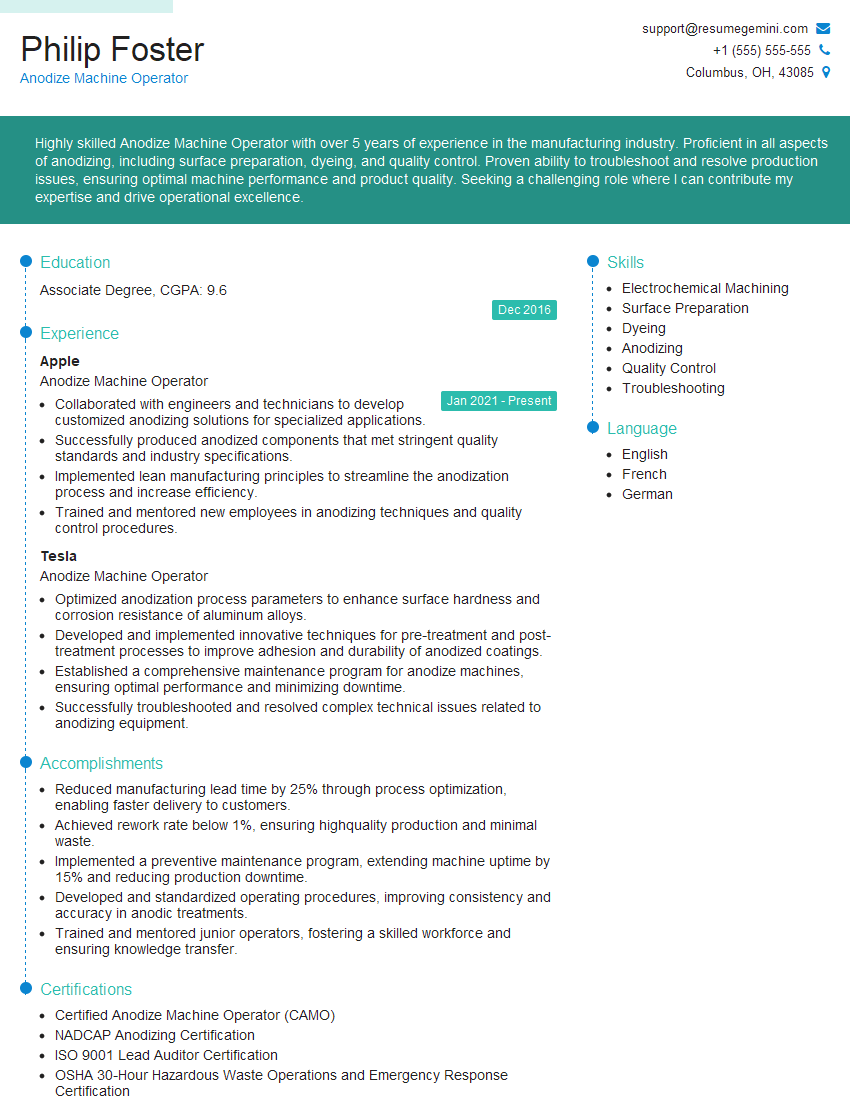

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Anodize Machine Operator

1. Explain the anodizing process and its benefits?

- Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, and wear-resistant anodic oxide finish.

- Anodizing improves the surface properties of the metal, making it suitable for various applications such as aerospace, automotive, and consumer electronics.

2. What are the different types of anodizing processes?

- Chromic acid anodizing: Produces a thin, clear, and corrosion-resistant oxide layer.

- Sulfuric acid anodizing: Creates a thicker, harder, and more wear-resistant oxide layer.

- Hard anodizing: Forms a very thick, hard, and abrasion-resistant oxide layer.

3. Describe the steps involved in the anodizing process?

- Pre-treatment: Cleaning, etching, and preparing the metal surface.

- Anodizing: Submerging the metal in an electrolytic bath and passing an electric current through it.

- Sealing: Hydrating the oxide layer to enhance its corrosion resistance.

4. What are the factors that affect the quality of the anodized finish?

- Alloy composition: Different alloys have different anodizing characteristics.

- Anodizing parameters: Voltage, current, temperature, and time.

- Surface preparation: The cleanliness and roughness of the metal surface.

5. Explain the role of the anodize machine operator?

- Monitoring and controlling the anodizing process: Ensuring optimal parameters and process consistency.

- Loading and unloading the workpieces: Handling materials and ensuring proper placement in the anodizing tank.

- Inspecting the anodized parts: Checking for defects and ensuring quality standards.

6. How do you troubleshoot common anodizing problems?

- Poor adhesion: Insufficient surface preparation or improper sealing.

- Discoloration: Contamination or improper rinsing.

- Pitting: Inadequate cleaning or etching.

7. What safety precautions should be taken when operating an anodizing machine?

- Chemical safety: Handling acids and bases with proper PPE.

- Electrical safety: Grounding equipment and wearing insulated gloves.

- Ventilation: Ensuring proper ventilation to remove fumes.

8. Explain how to use anodizing equipment to achieve specific results?

- Adjusting parameters: Modifying voltage, current, temperature, and time to obtain desired oxide thickness and finish.

- Utilizing fixtures: Configuring fixtures to ensure proper part positioning for uniform anodizing.

- Monitoring and controlling processes: Using sensors and data loggers to track process parameters and maintain consistency.

9. How do you maintain anodizing equipment to ensure optimal performance?

- Regular cleaning: Cleaning tanks, filters, and fixtures to prevent contamination.

- Calibration: Verifying and adjusting instruments to ensure accurate readings.

- Preventive maintenance: Inspecting and replacing worn or damaged components to avoid breakdowns.

10. What are the latest advancements in anodizing technology?

- Plasma electrolytic oxidation (PEO): Creating thick, porous, ceramic-like oxide coatings.

- Micro-arc oxidation (MAO): Producing hard and wear-resistant coatings with improved corrosion resistance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Anodize Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Anodize Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Anodize Machine Operators are responsible for operating anodizing machines, which apply a protective oxide layer to metal surfaces. They must ensure that the anodizing process is carried out according to specifications, and that the finished product meets quality standards.

1. Operating Anodizing Machines

Anodize Machine Operators are responsible for operating anodizing machines, which apply a protective oxide layer to metal surfaces. They must ensure that the anodizing process is carried out according to specifications, and that the finished product meets quality standards.

- Loading and unloading parts onto and from the machine.

- Setting up and operating the machine according to the process specifications.

- Monitoring the anodizing process and making adjustments as necessary.

- Ensuring that the finished product meets quality standards.

2. Maintaining Anodizing Machines

Anodize Machine Operators are responsible for maintaining anodizing machines, which apply a protective oxide layer to metal surfaces. They must ensure that the machines are in good working order, and that they are calibrated and adjusted according to specifications.

- Cleaning and lubricating the machine.

- Calibrating and adjusting the machine according to specifications.

- Replacing worn or damaged parts.

- Troubleshooting and repairing the machine.

3. Quality Control

Anodize Machine Operators are responsible for ensuring that the finished product meets quality standards. They must inspect the finished product for defects, and they must take corrective action as necessary.

- Inspecting the finished product for defects.

- Taking corrective action as necessary.

- Maintaining records of quality control inspections.

4. Safety

Anodize Machine Operators must follow all safety procedures, and they must wear appropriate personal protective equipment. They must also be aware of the hazards associated with the anodizing process, and they must take steps to minimize the risk of injury.

- Following all safety procedures.

- Wearing appropriate personal protective equipment.

- Being aware of the hazards associated with the anodizing process.

- Taking steps to minimize the risk of injury.

Interview Tips

Preparing for an interview for an Anodize Machine Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and the Position

Before you go to the interview, take some time to research the company and the position. This will help you understand the company’s culture and values, and it will also help you to tailor your answers to the interviewer’s questions.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company, if possible.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions.

- Practice saying your answers out loud.

- Get feedback from a friend or family member.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills, so be prepared to talk about them in detail. Be sure to highlight your experience with anodizing machines, and your ability to operate and maintain them.

- Quantify your experience and skills whenever possible.

- Use specific examples to illustrate your points.

- Be enthusiastic and positive when talking about your experience and skills.

4. Be Prepared to Answer Questions About Safety

Safety is a very important aspect of anodizing, so be prepared to answer questions about your safety procedures. Be sure to emphasize your commitment to safety, and your knowledge of the hazards associated with the anodizing process.

- Describe your safety procedures in detail.

- Explain how you would handle a safety hazard.

- Be familiar with the OSHA regulations for anodizing.

5. Be Prepared to Ask Questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is a great opportunity to learn more about the company and the position, and to show the interviewer that you are interested and engaged.

- Prepare a few questions to ask the interviewer.

- Ask questions about the company, the position, and the anodizing process.

- Be respectful and professional when asking your questions.

Next Step:

Now that you’re armed with the knowledge of Anodize Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Anodize Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini