Feeling lost in a sea of interview questions? Landed that dream interview for Anodizer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Anodizer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

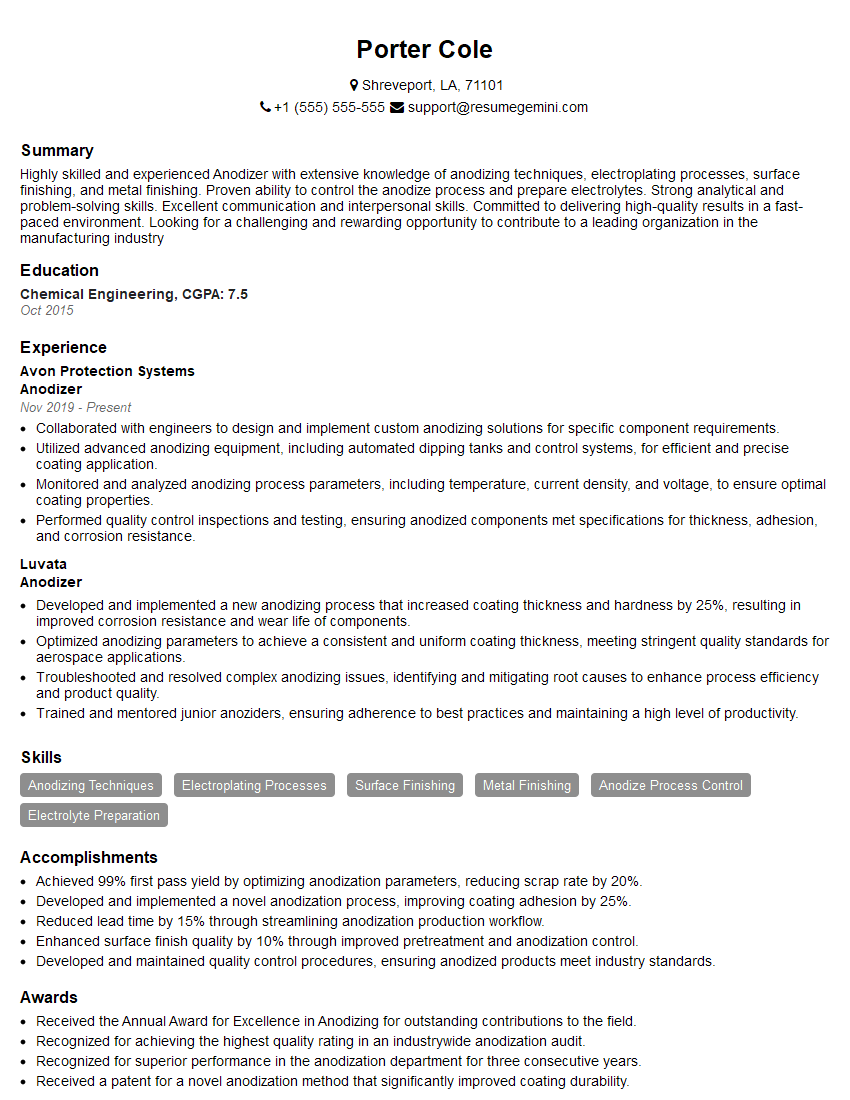

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Anodizer

1. What are the different types of anodizing processes?

The different types of anodizing processes include:

- Chromic acid anodizing: This is the most common type of anodizing, and it produces a thin, transparent oxide layer that is resistant to corrosion and wear.

- Sulfuric acid anodizing: This process produces a thicker oxide layer that is harder and more wear-resistant than chromic acid anodizing, but it is also less corrosion-resistant.

- Hard anodizing: This process produces an extremely hard and wear-resistant oxide layer, but it is also more brittle than other types of anodizing.

2. What are the advantages of anodizing?

Improved corrosion resistance

- Anodizing creates a protective oxide layer on the surface of the metal, which prevents it from coming into contact with oxygen and moisture.

- This makes the metal much more resistant to corrosion, even in harsh environments.

Increased wear resistance

- The oxide layer created by anodizing is also very hard and durable.

- This makes it resistant to wear and tear, even in demanding applications.

Improved electrical insulation

- The oxide layer created by anodizing is an excellent electrical insulator.

- This makes it ideal for use in electrical applications, where it can prevent short circuits and other electrical problems.

Enhanced cosmetic appearance

- Anodizing can be used to create a variety of colors and finishes on metal surfaces.

- This makes it a popular choice for decorative applications, such as jewelry and architectural features.

3. What are the disadvantages of anodizing?

The disadvantages of anodizing include:

- Increased cost: Anodizing is a relatively expensive process, compared to other metal finishing methods.

- Reduced strength: The oxide layer created by anodizing can reduce the strength of the metal.

- Limited durability: The oxide layer created by anodizing can be damaged by abrasion or other harsh conditions.

4. What are the key factors that affect the quality of an anodized finish?

- The type of metal being anodized: Different metals have different properties, which can affect the quality of the anodized finish.

- The anodizing process parameters: The temperature, time, and voltage used in the anodizing process can all affect the quality of the finish.

- The quality of the pre-treatment: The surface of the metal must be properly cleaned and prepared before anodizing, or the finish will be poor.

- The quality of the post-treatment: The anodized finish must be properly sealed after anodizing, or it will be vulnerable to corrosion.

5. What are the most common problems that can occur during anodizing?

- Poor adhesion: The oxide layer may not adhere properly to the metal surface, which can lead to peeling or flaking.

- Discoloration: The oxide layer may be discolored, which can be caused by a variety of factors, such as impurities in the metal or the anodizing solution.

- Pitting: The oxide layer may contain pits, which can be caused by a variety of factors, such as contamination of the metal or the anodizing solution.

- Burning: The metal may be burned during anodizing, which can be caused by excessive temperature or voltage.

6. What are the steps involved in the anodizing process?

The steps involved in the anodizing process include:

- Cleaning: The metal surface must be cleaned to remove any dirt, oil, or other contaminants.

- Pre-treatment: The metal surface may be treated with a chemical solution to improve the adhesion of the oxide layer.

- Anodizing: The metal is placed in an electrolytic bath and an electric current is passed through the solution. This causes an oxide layer to form on the surface of the metal.

- Post-treatment: The anodized finish may be sealed to improve its corrosion resistance and durability.

7. What are the different types of equipment used in the anodizing process?

- Anodizing tanks: These tanks hold the electrolytic solution used in the anodizing process.

- Power supplies: These supplies provide the electric current used in the anodizing process.

- Agitators: These devices circulate the electrolytic solution to ensure that the metal surface is evenly anodized.

- Filters: These devices remove impurities from the electrolytic solution.

8. What are the safety precautions that must be taken when working with anodizing chemicals?

- Wear appropriate personal protective equipment (PPE): This includes gloves, eye protection, and a respirator.

- Handle chemicals safely: Avoid skin contact and do not ingest chemicals.

- Store chemicals properly: Store chemicals in a cool, dry place away from incompatible materials.

- Dispose of chemicals properly: Dispose of chemicals according to local regulations.

9. What are the environmental regulations that apply to anodizing?

- Clean Water Act: This act regulates the discharge of pollutants into waterways.

- Resource Conservation and Recovery Act (RCRA): This act regulates the generation, storage, and disposal of hazardous waste.

- Toxic Substances Control Act (TSCA): This act regulates the manufacture, distribution, and use of toxic substances.

10. What are the career opportunities for an anodizer?

- Anodizing technician: This is the most common career opportunity for anodizers.

- Anodizing engineer: This position is responsible for the design and operation of anodizing systems.

- Anodizing sales representative: This position is responsible for selling anodizing services to customers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Anodizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Anodizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Anodizer is responsible for anodizing metal surfaces to enhance their properties and aesthetics.

1. Surface Preparation

Prepares metal surfaces for anodizing by cleaning, degreasing, and etching.

2. Anodizing Process

Operates anodizing equipment and controls process parameters to achieve desired surface properties.

3. Quality Control

Inspects anodized surfaces for quality and conformance to specifications.

4. Maintenance and Troubleshooting

Performs regular maintenance on anodizing equipment and troubleshoots any issues.

Interview Tips

To ace an interview for an Anodizer position, candidates should prepare thoroughly and highlight their relevant skills and experience.

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and services. Research the Anodizer position to understand its specific responsibilities and requirements.

2. Practice Answering Common Interview Questions

Prepare responses to common interview questions, such as:

- Tell me about your experience in anodizing.

- Describe the anodizing process and its benefits.

- How do you ensure the quality of anodized surfaces?

3. Showcase Your Technical Skills

Highlight your technical skills and knowledge of anodizing equipment, processes, and materials. Provide specific examples to demonstrate your proficiency.

4. Emphasize Your Attention to Detail

Emphasize your attention to detail and commitment to quality control. Explain how you ensure that anodized surfaces meet specifications and customer expectations.

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows your interest in the position and the company. Consider questions about the company’s growth plans, the anodizing department’s priorities, or future advancements in the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Anodizer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!