Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Antichecking Iron Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

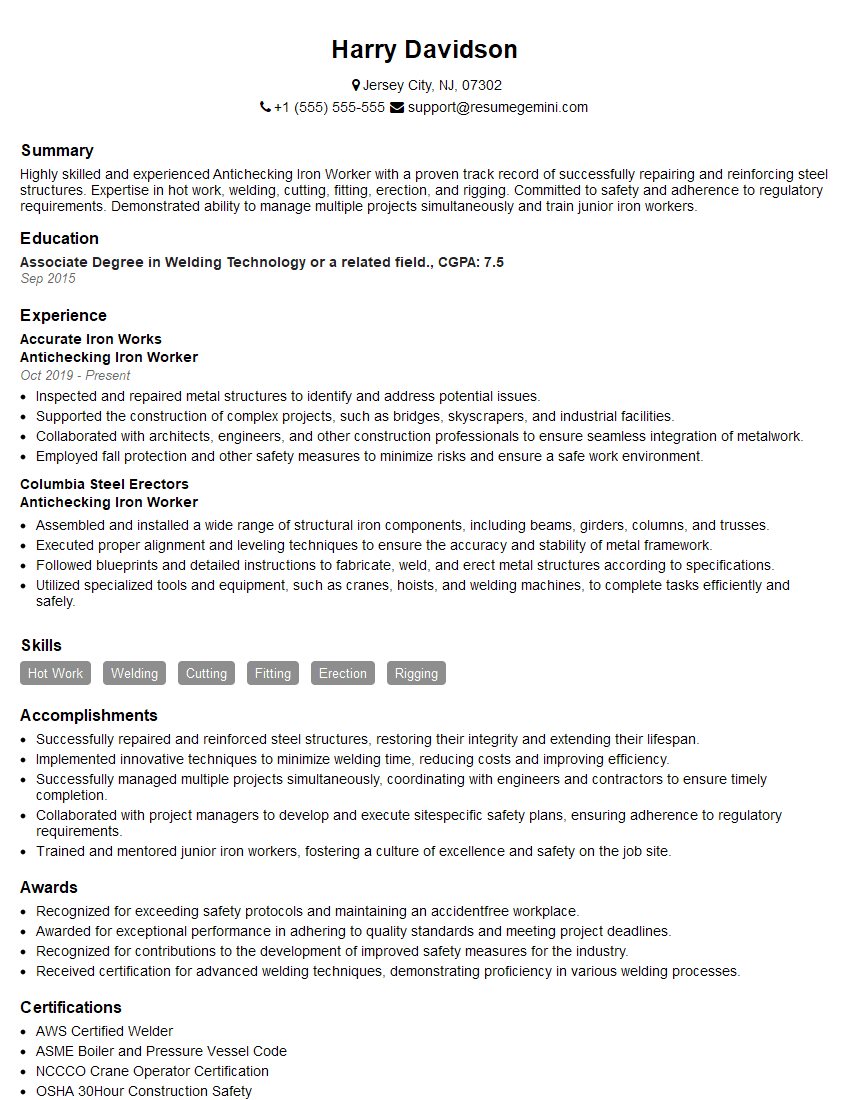

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Antichecking Iron Worker

1. What methods do you use to ensure anchoring of the anti-checking ironwork is secure?

- Verify that the backing surface can support the load and that the anchors are specified for the appropriate weight.

- Use a torque wrench to tighten anchors to the manufacturer’s specifications.

- Check all anchors for tightness before any load is applied.

- Inspect anchors regularly and tighten any that have loosened.

2. How do you determine the appropriate gauge and type of anti-checking ironwork for a specific application?

Material Strength and Stiffness

- Consider the material strength and stiffness to withstand the anticipated loads and deformations.

- Consult industry standards and guidelines for material selection.

Load Analysis

- Analyze the forces and loads that the anti-checking ironwork will be subjected to.

- Calculate bending moments, shear forces, and deflections to determine the required gauge and section properties.

Environmental Conditions

- Consider the environmental conditions, such as temperature, humidity, and corrosion resistance, to select the appropriate material and coating.

- Ensure the material is suitable for the anticipated exposure conditions.

3. How do you handle the installation of anti-checking ironwork in areas with tight access or limited space?

- Use specialized tools and techniques to manipulate and install the ironwork in confined spaces.

- Pre-assemble components to minimize on-site work.

- Coordinate with other trades to ensure adequate access and avoid conflicts.

- Use lightweight materials and consider alternative installation methods, such as magnetic or adhesive systems.

4. What safety precautions do you take when working with anti-checking ironwork?

- Wear appropriate personal protective equipment such as gloves, safety glasses, and a hard hat.

- Inspect the work area for potential hazards and take necessary precautions.

- Follow established safety protocols for handling and installing metal components.

- Operate machinery and equipment safely and according to the manufacturer’s instructions.

- Stay alert and aware of surroundings to prevent accidents.

5. How do you ensure the quality and durability of anti-checking ironwork installations?

- Adhere to industry standards and best practices for installation.

- Use high-quality materials and components that meet specifications.

- Follow proper installation procedures and ensure proper alignment and support.

- Inspect the installation upon completion and make any necessary adjustments.

- Provide ongoing maintenance and inspection to ensure the continued performance of the anti-checking ironwork.

6. Describe the different types of anti-checking ironwork materials and their applications.

- Steel: Durable, strong, and versatile; used in various applications.

- Aluminum: Lightweight, corrosion-resistant, and suitable for non-load-bearing applications.

- Stainless Steel: Highly corrosion-resistant, ideal for applications exposed to moisture or chemicals.

- Composite Materials: Combinations of different materials, offering specific properties such as high strength-to-weight ratios and corrosion resistance.

7. Explain the importance of regular inspection and maintenance of anti-checking ironwork.

- Early Detection of Issues: Regular inspections can identify potential problems, such as corrosion or damage, at an early stage.

- Preventive Maintenance: Maintenance tasks, such as tightening bolts and repainting, help prevent failures and extend the life of the ironwork.

- Safety: Proper maintenance ensures the structural integrity and safety of the anti-checking ironwork, reducing the risk of accidents.

- Compliance: Regular inspections and maintenance can help meet industry standards and regulations.

8. How do you troubleshoot and resolve common issues with anti-checking ironwork?

Corrosion

- Identify the source of corrosion and eliminate it if possible.

- Clean the affected area and apply a protective coating.

Loose Connections

- Inspect all bolts and nuts for tightness.

- Tighten any loose connections to ensure structural stability.

Damage

- Assess the extent of damage and determine the cause.

- Repair or replace damaged components as necessary.

9. What techniques and equipment do you use to install anti-checking ironwork?

- Welding: Used to join metal components permanently.

- Bolting: Used to fasten ironwork to supporting structures.

- Riveting: Used to connect ironwork using rivets.

- Specialized Equipment: May include lifts, cranes, and scaffolding for accessing and manipulating heavy components.

10. Describe your experience in working with structural engineers and architects on the design and implementation of anti-checking ironwork.

- Collaborated with engineers to interpret drawings and determine appropriate installation methods.

- Provided input on material selection and design considerations.

- Worked with architects to ensure aesthetic and functional requirements were met.

- Communicated regularly to coordinate schedules and resolve technical issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Antichecking Iron Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Antichecking Iron Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Antichecking Iron Worker is responsible for performing various tasks related to the fabrication and installation of structural steel and metal components. Key responsibilities include:

1. Fabrication and Erection

Fabricate and assemble structural steel members, such as beams, columns, and girders, according to blueprints and specifications.

2. Welding

Perform welding operations using various techniques, such as arc welding, MIG welding, and TIG welding, to join metal components.

3. Rigging

Operate cranes and rigging equipment to lift and position structural steel components during installation.

4. Cutting and Shaping

Use cutting tools and equipment to cut and shape metal materials to meet specifications.

5. Inspection and Maintenance

Inspect structural steel components and systems for damage or defects, and perform maintenance tasks as needed.

6. Safety

Adhere to safety regulations and procedures, and wear appropriate personal protective equipment.

Interview Tips

Preparing for an interview for an Antichecking Iron Worker position requires thorough preparation and a clear understanding of the role. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific Antichecking Iron Worker position. This will help you understand the company’s culture, values, and the specific requirements of the role.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Highlight your proficiency in welding, fabrication, rigging, and other related skills.

3. Prepare for Common Interview Questions

Prepare for common interview questions related to your experience, skills, and qualifications. Practice answering questions about your welding techniques, fabrication experience, and safety procedures.

4. Demonstrate Attention to Safety

Emphasize your commitment to safety and adherence to industry regulations. Provide specific examples of your safety practices and experience.

5. Show Enthusiasm and Interest

Express your enthusiasm for the role and demonstrate your interest in working for the company. Show that you are passionate about the industry and eager to contribute your skills.

6. Prepare Questions for the Interviewer

Prepare thoughtful questions to ask the interviewer about the company, the role, and the industry. This shows your engagement and interest in the opportunity.

7. Practice and Seek Feedback

Practice your interview skills by conducting mock interviews with a friend, family member, or career counselor. Seek feedback on your presentation, body language, and answers to common questions.

8. Dress Professionally and Arrive on Time

Dress professionally and arrive at the interview punctually. This demonstrates respect for the company and the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Antichecking Iron Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!