Feeling lost in a sea of interview questions? Landed that dream interview for Anvil Seating Press Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Anvil Seating Press Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

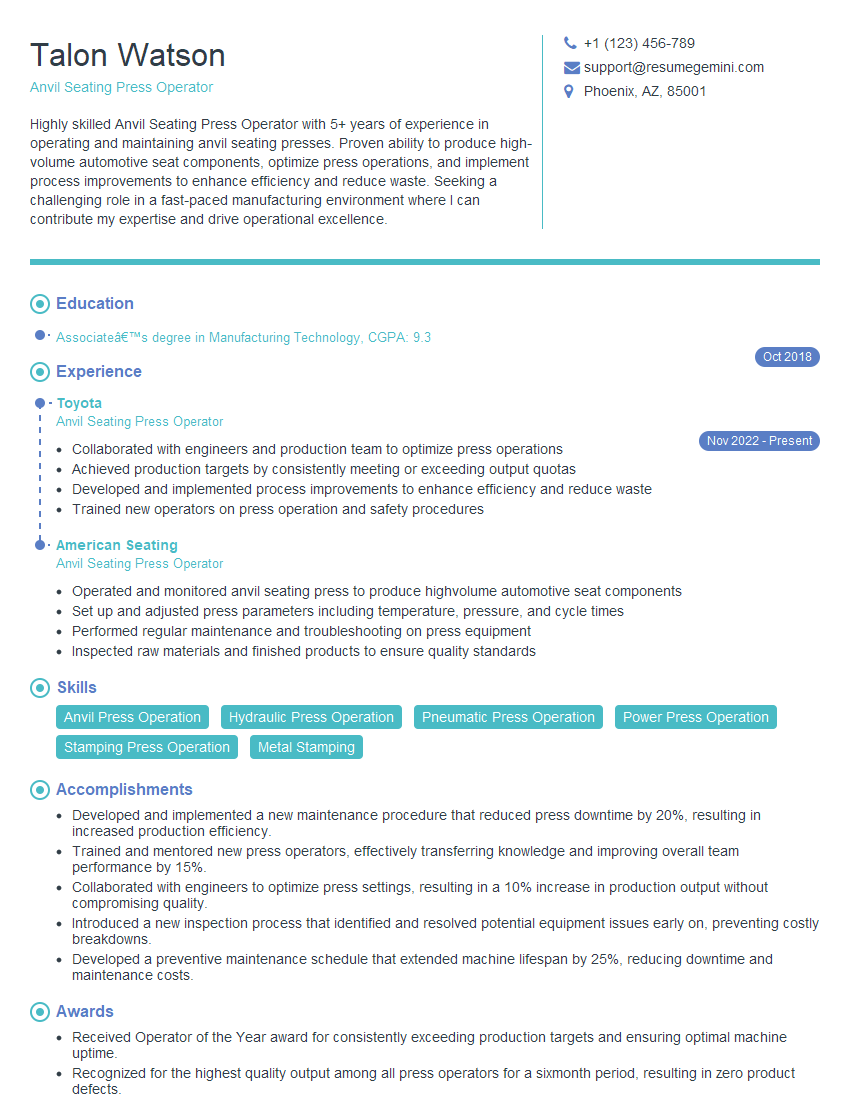

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Anvil Seating Press Operator

1. How do you ensure the accuracy and precision of the seating components produced on the anvil press?

To ensure accuracy and precision, I follow a comprehensive process that includes:

- Regularly calibrating and maintaining the press according to manufacturer specifications.

- Using precision measuring tools to verify the dimensions and tolerances of each component.

- Implementing statistical process control (SPC) techniques to monitor and adjust the process as needed.

- Adhering to established quality control procedures and standards throughout the production process.

2. Describe the safety guidelines and protocols you follow when operating the anvil press.

Adherence to Regulations

- Thoroughly familiarizing myself with all relevant safety regulations and standards.

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

Risk Assessment and Mitigation

- Conducting a thorough risk assessment before starting any operation.

- Identifying potential hazards and implementing appropriate control measures to minimize risks.

Emergency Preparedness

- Being aware of emergency procedures and the location of safety equipment.

- Knowing how to respond quickly and effectively in case of an emergency.

3. How do you troubleshoot and resolve common issues that may arise during anvil press operation?

When troubleshooting common issues, I follow a systematic approach:

- Identifying the problem and its symptoms.

- Checking for loose connections, worn parts, or other potential causes.

- Consulting technical manuals and resources for guidance.

- Implementing appropriate corrective actions, such as adjusting settings, replacing parts, or performing maintenance.

- Verifying that the issue has been resolved and the press is operating properly.

4. How do you maintain and service the anvil press to ensure optimal performance?

To ensure optimal performance, I conduct regular maintenance and service tasks:

- Cleaning and lubricating the press according to the manufacturer’s recommendations.

- Inspecting and replacing worn or damaged parts promptly.

- Monitoring the press’s performance and making adjustments as needed.

- Performing preventive maintenance tasks, such as checking fluid levels and tightening bolts.

- Keeping a detailed maintenance log to track all service activities.

5. How do you optimize the anvil press settings to achieve maximum efficiency and productivity?

I optimize press settings through a combination of experience and data analysis:

- Consulting with engineers and production managers to determine optimal settings for different materials and components.

- Running test batches to fine-tune settings and identify the most efficient parameters.

- Monitoring press performance and making adjustments to improve cycle times and reduce waste.

- Utilizing automation and technology to streamline the optimization process.

6. How do you ensure that the anvil press is operating within specified tolerances?

Maintaining operation within specified tolerances is crucial for product quality:

- Using precision measuring tools to verify the dimensions and tolerances of each component.

- Implementing statistical process control (SPC) techniques to monitor and adjust the process as needed.

- Calibrating the press regularly to ensure accuracy.

- Following established quality control procedures and standards throughout the production process.

7. How do you handle high-volume production and meet tight deadlines without compromising quality?

To manage high-volume production while maintaining quality, I employ several strategies:

- Optimizing press settings and processes to maximize efficiency and productivity.

- Implementing lean manufacturing principles to reduce waste and improve workflow.

- Ensuring that the press is properly maintained and serviced to minimize downtime.

- Working closely with the production team to coordinate schedules and ensure timely delivery.

8. What experience do you have in working with different types of materials and tooling on the anvil press?

Throughout my experience as an Anvil Seating Press Operator, I have worked with a wide range of materials and tooling:

- Metals: Steel, aluminum, and stainless steel.

- Plastics: ABS, PVC, and polycarbonate.

- Tooling: Dies, punches, and molds.

- Experience in both manual and automated press operations.

9. How do you stay updated on the latest technologies and advancements in anvil press operation?

To keep abreast of the latest technologies and advancements, I take the following steps:

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Consulting with experts and manufacturers in the field.

- Seeking opportunities for professional development and training.

10. What are your strengths and weaknesses as an Anvil Seating Press Operator?

My strengths include:

- Strong technical skills and a deep understanding of anvil press operation.

- Proven ability to maintain accuracy and precision in high-volume production.

- Excellent problem-solving and troubleshooting abilities.

- Experience in working with different materials and tooling.

My weakness is that:

- I have limited experience with automated press systems.

However, I am eager to learn and develop my skills in this area.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Anvil Seating Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Anvil Seating Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Anvil Seating Press Operator operates a machine that presses and assembles metal components for seating products, such as chairs and sofas.

1. Machine Operation

The operator positions the metal components accurately in the press, following a specific pattern or design. They then activate the press, which presses the components together with high force, forming the desired shape.

- Adjust and maintain the press machine to ensure optimal performance and safety.

- Set up and position the metal components accurately according to the specified design.

2. Quality Inspection

The operator visually inspects the pressed components for defects, such as cracks, scratches, or misalignments. They also measure the dimensions of the components to ensure they meet the required specifications.

- Inspect pressed components for any defects or quality issues.

- Measure and verify the dimensions of the pressed components using measuring tools, such as calipers or micrometers.

3. Maintenance and Troubleshooting

The operator performs routine maintenance on the press machine, including cleaning, lubrication, and minor repairs. They also troubleshoot any problems that may arise during operation, ensuring that the machine is functioning properly.

- Perform regular maintenance and cleaning of the press machine.

- Troubleshoot and resolve any technical issues that may arise during operation.

4. Safety Compliance

The operator follows all safety regulations and procedures, including wearing appropriate protective gear and following established protocols for handling heavy equipment or moving parts.

- Adhere to all safety regulations and protocols, such as wearing protective gear.

- Follow established procedures for handling heavy equipment and moving parts.

Interview Tips

To ace an interview for an Anvil Seating Press Operator position, it’s important to prepare and showcase your skills and experience that align with the job responsibilities and requirements.

1. Research the Company and Role

Before the interview, research the company and the specific role you are applying for. This will help you understand their business, industry, and the particular responsibilities and expectations for the position.

- Visit the company’s website to learn about their products, services, and company culture.

- Read industry publications and news to stay up-to-date on the latest trends and technologies in the field.

2. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the job requirements. Quantify your accomplishments and provide specific examples of your work to demonstrate your capabilities.

- Describe your experience in operating press machines and assembling metal components.

- Highlight your ability to inspect products for defects and ensure quality standards.

3. Show Enthusiasm and Passion

Express your enthusiasm and passion for the role and the industry. Show that you are genuinely interested in the company and the opportunity, and that you are eager to contribute your skills and experience.

- Prepare questions to ask the interviewer, demonstrating your interest and engagement.

- Share your knowledge of the industry and your understanding of the company’s products or services.

4. Practice and Prepare

Practice answering common interview questions and prepare examples that showcase your skills and experience. The more prepared you are, the more confident and articulate you will appear during the interview.

- Research typical interview questions and prepare thoughtful responses.

- Practice your answers in front of a mirror or with a friend or family member for feedback.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Anvil Seating Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Anvil Seating Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.