Are you gearing up for a career in Apparel Manufacture Instructor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Apparel Manufacture Instructor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

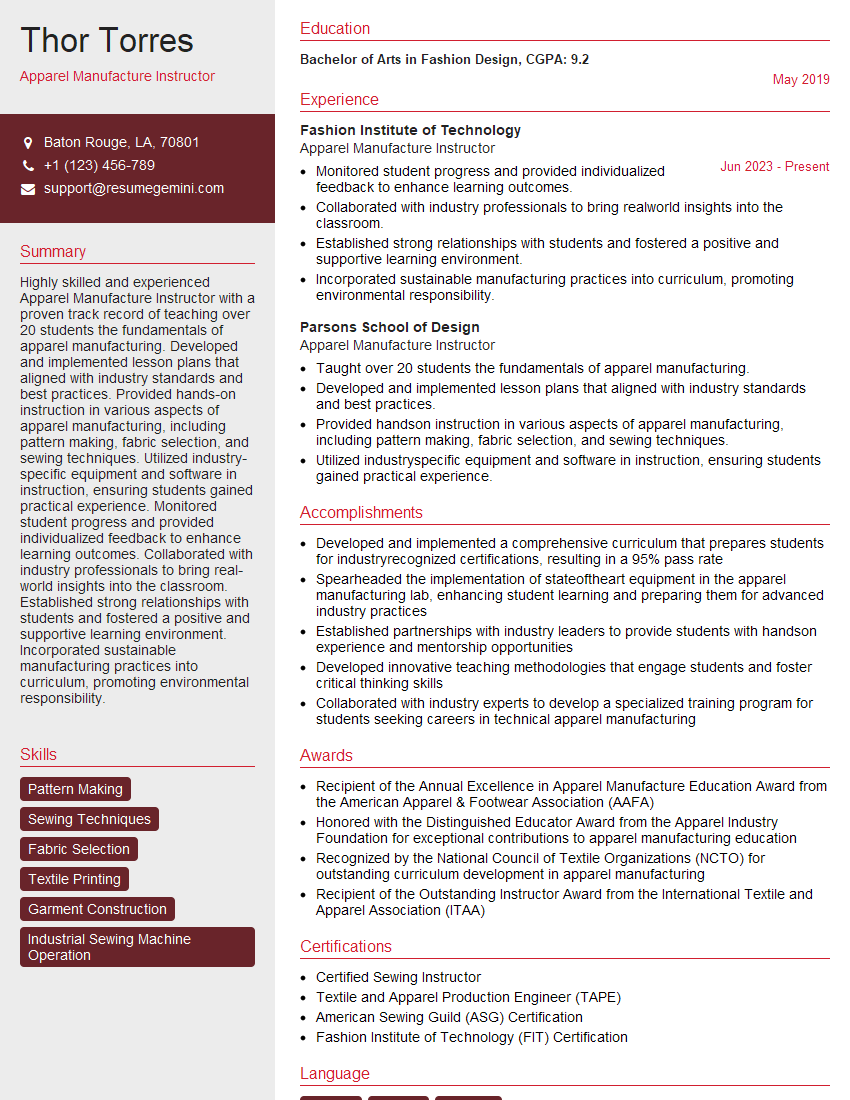

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Apparel Manufacture Instructor

1. Describe the different types of sewing machines used in apparel manufacturing.

In a typical apparel manufacturing setup, there are several types of sewing machines commonly used. Here are the key types:

- Single-needle lockstitch machine: This is the most basic type of sewing machine, used for straight stitching and is commonly used in the construction of garments.

- Overlock machine: Also known as a serger, this machine is used for finishing raw edges of fabrics, preventing fraying.

- Coverstitch machine: This specialized machine creates a decorative and stretchy stitch, commonly used for hemming and attaching cuffs.

- Buttonhole machine: As the name suggests, this machine is used for creating buttonholes on garments.

- Bar tacking machine: Used for reinforcing areas of garments that experience stress, such as pocket corners or belt loops.

2. What are the key factors to consider when selecting fabrics for apparel manufacturing?

When selecting fabrics for apparel manufacturing, several key factors need to be considered to ensure the desired outcome:

- Fiber content: The type of fiber used, such as cotton, polyester, nylon, or a blend, determines the fabric’s properties like breathability, drape, and durability.

- Weave or knit: The construction of the fabric, whether woven or knitted, affects its texture, stretch, and drape.

- Weight and thickness: The weight and thickness of the fabric influence its suitability for different garment types and seasons.

- Color and pattern: The color and pattern of the fabric impact the overall aesthetics of the garment.

- Cost and availability: The cost and availability of the fabric are important considerations for production planning.

3. Explain the steps involved in pattern making for apparel manufacturing.

Pattern making for apparel manufacturing involves a series of steps to create a template for cutting and sewing garments.

- Taking measurements: Accurate body measurements are taken to ensure a proper fit.

- Creating a bodice block: A basic bodice block is constructed based on the measurements, serving as the foundation for all other garment patterns.

- Adding style details: Design elements like collars, sleeves, and pockets are incorporated into the bodice block to create the desired garment shape.

- Grading: The pattern is graded to create different sizes based on the original measurements.

- Marker making: The pattern pieces are arranged efficiently on a marker to minimize fabric waste during cutting.

4. Describe the different methods used for garment construction.

There are various methods used for garment construction, each with its advantages and applications:

- Flat pattern cutting: Patterns are laid flat on the fabric, and pieces are cut and sewn together to form the garment.

- Bias cutting: Fabric is cut on the bias, creating garments with a unique drape and stretch.

- Draping: Fabric is draped directly on a dress form to create unique and custom-fitted garments.

- Knitting: Garments are created by knitting loops of yarn together, producing stretchy and comfortable pieces.

5. Explain the importance of quality control in apparel manufacturing.

Quality control plays a crucial role in apparel manufacturing to ensure that garments meet the desired standards and customer expectations:

- Maintaining consistency: Quality control processes help ensure that garments are produced consistently, meeting specifications for size, fit, and appearance.

- Defect detection: Regular inspections and testing identify and eliminate defects in materials, construction, and finishing.

- Customer satisfaction: High-quality garments lead to satisfied customers, enhancing the reputation of the manufacturer and increasing sales.

- Cost reduction: By identifying and correcting defects early on, manufacturers can reduce production costs and avoid costly rework or recalls.

6. What are the sustainability considerations in apparel manufacturing?

Sustainability has become increasingly important in apparel manufacturing, addressing environmental and social concerns:

- Environmentally friendly materials: Using sustainable fibers like organic cotton, recycled polyester, and bamboo reduces the impact on the environment.

- Ethical production: Ensuring fair labor practices, safe working conditions, and reasonable wages for workers.

- Waste reduction: Implementing waste reduction techniques, such as efficient fabric cutting and recycling, minimizes environmental impact.

- Energy conservation: Utilizing energy-efficient equipment and production processes reduces the carbon footprint.

7. Describe the challenges and rewards of teaching apparel manufacturing.

Teaching apparel manufacturing comes with both challenges and rewards:

Challenges:

- Keeping up with technology: The apparel industry is constantly evolving, and instructors need to stay updated with the latest technologies and techniques.

- Managing a diverse student body: Students come from different backgrounds and experience levels, requiring tailored teaching approaches.

Rewards:

- Seeing students succeed: Witnessing students develop their skills and achieve their goals is incredibly rewarding.

- Nurturing creativity: Apparel manufacturing allows students to express their creativity and develop their artistic side.

8. What are your favorite teaching methods for apparel manufacturing?

My favorite teaching methods for apparel manufacturing include:

- Hands-on practice: Providing students with hands-on experience on industry-standard equipment helps them develop practical skills.

- Visual aids: Using visual aids like diagrams, videos, and samples enhances understanding and retention.

- Project-based learning: Assigning students projects that simulate real-world manufacturing processes fosters problem-solving and teamwork.

- Guest speakers: Inviting industry professionals to share their expertise and experiences provides valuable insights.

9. How do you assess student learning in apparel manufacturing?

I assess student learning in apparel manufacturing through a combination of methods:

- Practical skills: Evaluating students’ ability to operate equipment, construct garments, and troubleshoot problems.

- Written assignments: Assigning essays, reports, or design portfolios to assess their understanding of concepts and theories.

- Projects: Grading students on their ability to complete projects that demonstrate their skills and knowledge.

- Class participation: Encouraging active participation in discussions and asking questions to gauge their comprehension.

10. What are your goals as an Apparel Manufacture Instructor?

As an Apparel Manufacture Instructor, my goals are to:

- Empower students: Provide students with the knowledge, skills, and confidence to succeed in the apparel manufacturing industry.

- Foster innovation: Encourage students to think creatively and develop innovative solutions to manufacturing challenges.

- Promote sustainability: Integrate sustainable practices into teaching to raise awareness of the environmental and social implications of apparel manufacturing.

- Stay current: Continuously update my knowledge and skills to stay abreast of industry trends and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Apparel Manufacture Instructor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Apparel Manufacture Instructor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Apparel Manufacture Instructors are the professionals responsible for providing instructions and guidance to students in the field of apparel manufacturing. Their key responsibilities include:

1. Course Delivery and Development

Instructors plan and deliver engaging lessons, develop course materials, and incorporate industry-best practices to ensure students receive the most up-to-date knowledge and skills.

- Design and implement curriculum that aligns with industry standards.

- Develop teaching plans and materials, including lectures, handouts, and demonstrations.

2. Practical Training Supervision

Instructors guide students through hands-on training exercises, ensuring they develop essential technical skills. They provide detailed demonstrations, monitor progress, and offer constructive feedback.

- Supervise and guide students in the use of equipment and machinery.

- Provide personalized support and guidance to students with varying skill levels.

3. Student Assessment and Evaluation

Instructors evaluate students’ progress through assignments, projects, and exams. They provide timely feedback and constructive criticism to help students improve their skills and knowledge.

- Conduct assessments to evaluate students’ understanding of concepts and techniques.

- Provide detailed feedback to students on their performance, offering suggestions for improvement.

4. Student Support and Advising

Instructors serve as mentors and advisors to students, providing support and guidance beyond the classroom. They help students develop career goals, prepare for industry certification, and navigate the job application process.

- Provide guidance to students on career planning and job search strategies.

- Maintain open communication with students to address their concerns and support their academic journey.

Interview Preparation Tips

To increase your chances of success in the apparel manufacture instructor interview, consider the following preparation tips:

1. Research the Organization and Position

Delve into the institution’s history, mission, and faculty profiles. Understand the specific requirements of the instructor role and how your skills align with them.

2. Practice Your Teaching Skills

Prepare a 5-10 minute micro-lesson that showcases your teaching style and ability to engage students. Anticipate common questions about your teaching methods and prepare clear, concise answers.

3. Prepare for Technical Questions

Refresh your knowledge of industry-standard software, manufacturing techniques, and textile materials. Consider preparing a portfolio of your work or samples of student projects to demonstrate your expertise.

4. Highlight Your Communication Skills

Instructors are effective communicators. Practice articulating complex concepts clearly and engagingly. Show how you build relationships with students and foster a positive learning environment.

5. Showcase Your Passion

Let the interviewers know that you are passionate about teaching and have a genuine desire to help students succeed in the apparel manufacturing industry. Share anecdotes or experiences that highlight your enthusiasm for teaching.

Next Step:

Now that you’re armed with the knowledge of Apparel Manufacture Instructor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Apparel Manufacture Instructor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini