Are you gearing up for an interview for a Appliance Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Appliance Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

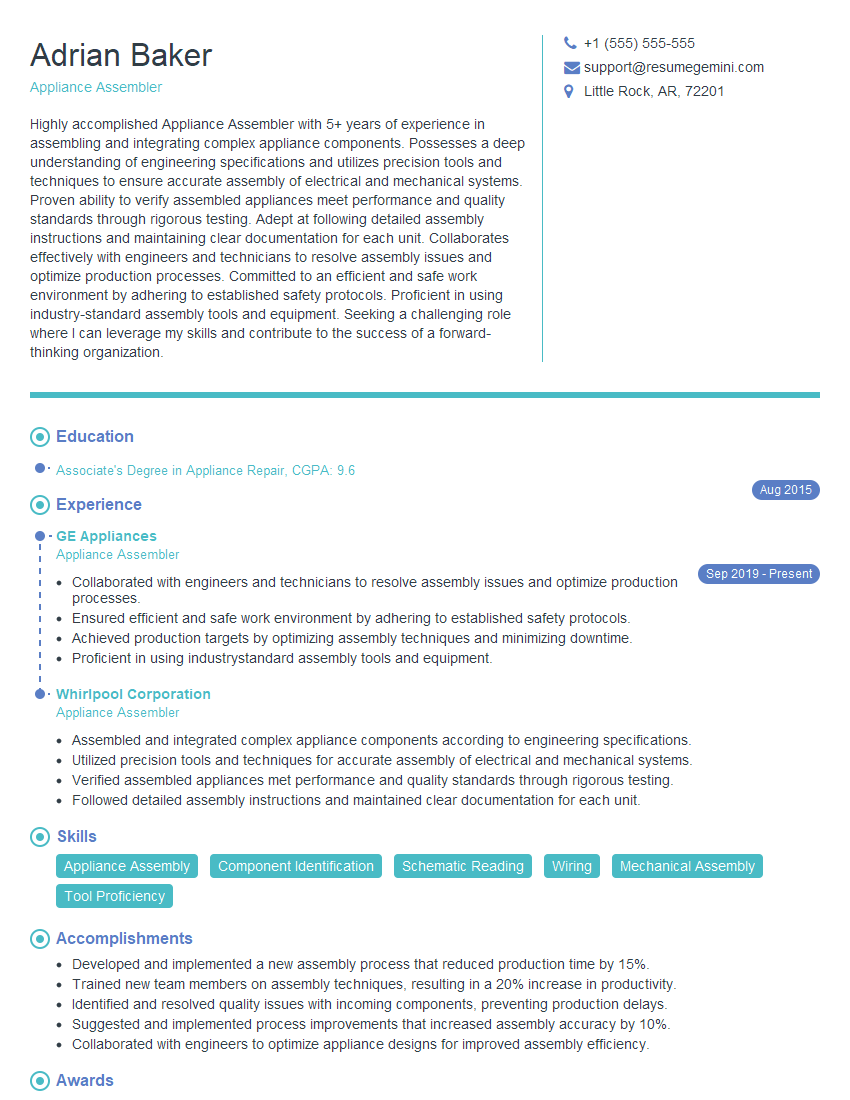

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Appliance Assembler

1. Describe your experience with assembling different types of appliances?

In my previous role as an Appliance Assembler at ABC Company, I was responsible for assembling a wide range of appliances, including refrigerators, stoves, dishwashers, and washing machines.

- I have experience working with various materials, including metal, plastic, and glass.

- I am proficient in using a variety of tools and equipment, including power drills, wrenches, and screwdrivers.

2. What are the key safety procedures that you follow when assembling appliances?

Proper Equipment

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Use the right tools for the job and ensure they are in good working condition.

Safe Handling

- Handle heavy components with care and use proper lifting techniques.

- Be aware of sharp edges and pinch points, and take precautions to avoid injury.

3. How do you troubleshoot common problems that arise during appliance assembly?

When troubleshooting common problems during appliance assembly, I follow a systematic approach:

- Identify the problem: Observe the symptoms and determine the affected component.

- Check connections: Verify that all electrical and mechanical connections are secure and properly made.

- Inspect components: Examine individual components for damage, wear, or misalignment.

- Refer to technical documentation: Consult manuals or diagrams to identify potential causes and solutions.

- Test and adjust: After addressing the issue, test the appliance and make necessary adjustments to ensure proper operation.

4. What are the different types of fasteners used in appliance assembly, and how do you choose the appropriate fastener for each application?

There are various types of fasteners used in appliance assembly, each suited for specific applications:

- Screws: Commonly used for attaching components due to their versatility and ability to create strong, permanent joints.

- Bolts: Provide a secure connection for heavier or structural components, often used with nuts and washers.

- Rivets: Permanent fasteners that create a strong bond between two pieces of metal.

- Snap-fits: Plastic fasteners that allow for quick assembly and disassembly, suitable for delicate components.

- Adhesives: Used to bond surfaces or seal gaps, providing additional strength or preventing leaks.

The choice of fastener depends on factors such as the materials being joined, the load requirements, and the desired level of permanence.

5. How do you ensure the quality of your assembled appliances?

I prioritize quality assurance throughout the assembly process:

- Thorough inspections: Conduct visual inspections at each stage to identify any defects or errors.

- Functional testing: Test the assembled appliances to verify their proper operation and performance.

- Calibration and adjustment: Ensure that all components are calibrated and adjusted according to specifications.

- Documentation: Maintain detailed records of assembly processes and quality checks for traceability.

- Continuous improvement: Seek feedback from colleagues and supervisors to identify areas for improvement and enhance quality standards.

6. What are the different types of electrical connections used in appliance assembly, and how do you ensure their safety and reliability?

There are various types of electrical connections used in appliance assembly, each with specific characteristics:

- Crimp connections: Used to create permanent, gas-tight connections by crimping a metal sleeve around wires.

- Soldered connections: Provide a strong and conductive bond by melting solder onto the joint.

- Screw terminals: Allow for easy and quick connections by tightening screws to secure wires.

- Push-in connectors: Enable fast and convenient connections without the need for tools.

To ensure safety and reliability, I adhere to the following practices:

- Use the correct type of connector for the specific application and wire gauge.

- Make sure connections are secure and properly insulated to prevent electrical hazards.

- Follow electrical codes and standards to maintain safety and compliance.

- Test connections for continuity and proper functionality before energizing the appliance.

7. How do you stay updated on the latest advancements and best practices in appliance assembly techniques?

To stay current with industry trends and best practices, I actively engage in continuous learning and development:

- Attend industry workshops and conferences: Network with peers and experts to learn about new technologies and techniques.

- Read trade publications and technical manuals: Stay informed about industry advancements and best practices.

- Participate in online forums and discussion groups: Engage with professionals to exchange knowledge and stay up-to-date.

- Seek feedback from supervisors and colleagues: Learn from experienced professionals and identify areas for improvement.

8. Describe a challenging appliance assembly project you worked on and how you overcame the challenges.

During my time at XYZ Company, I encountered a complex assembly project involving a high-end refrigerator.

- Challenge: The refrigerator had a unique cooling system that required precise alignment of multiple components.

- Solution: I carefully studied the technical documentation and consulted with senior technicians to understand the system’s intricacies.

- Result: I successfully assembled the refrigerator to specifications, ensuring optimal cooling performance.

9. How do you handle working in a fast-paced and demanding environment?

In fast-paced and demanding environments, I thrive by:

- Time management: Prioritize tasks, allocate time effectively, and meet deadlines without compromising quality.

- Teamwork: Collaborate with colleagues, share knowledge, and assist others to achieve common goals.

- Adaptability: Quickly adjust to changing priorities and handle multiple tasks simultaneously.

- Stress management: Stay calm under pressure, maintain focus, and deliver results even in challenging situations.

10. Why are you interested in this Appliance Assembler position at our company?

I am eager to join your esteemed organization as an Appliance Assembler for several reasons:

- Company reputation: Your company is renowned for its commitment to quality and innovation in the appliance industry.

- Career growth opportunities: I am confident that my skills and experience align well with the company’s growth trajectory, providing me with ample opportunities for professional development.

- Team environment: I am excited about the prospect of collaborating with a team of skilled and experienced professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Appliance Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Appliance Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities: Appliance Assembler

Appliance Assembly involves various crucial tasks. The following are key responsibilities of an Appliance Assembler:

1. Component Assembly

Assembling components of different appliances, including stoves, refrigerators, washing machines, dryers, and dishwashers.

- Following blueprints and instructions to ensure proper assembly.

- Utilizing tools and equipment to join components securely.

2. Equipment Calibration

Calibrating equipment such as sensors, switches, and electrical components to meet specifications.

- Using precision instruments to ensure accurate calibration.

- Testing equipment functionality before installation.

3. Installation and Testing

Installing appliances in accordance with manufacturer’s guidelines.

- Connecting electrical, water, and gas lines safely and securely.

- Testing appliances to ensure proper operation and compliance with standards.

4. Quality Control

Inspecting assembled appliances to ensure they meet quality standards.

- Checking for defects, damages, or missing components.

- Maintaining a clean and organized work area.

Interview Tips: Ace the Job as an Appliance Assembler

To successfully ace your interview for an Appliance Assembler position, consider these tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, products, and culture. Research the Appliance Assembler position, including responsibilities and requirements.

- Check the company website, LinkedIn page, and industry publications.

- Connect with current or former employees on LinkedIn for insights.

2. Highlight Relevant Experience and Skills

Showcase your previous experience in appliance assembly, manufacturing, or related fields.

- Emphasize your ability to assemble and install appliances accurately.

- Highlight your proficiency in using tools, equipment, and calibration instruments.

- Describe your attention to detail and commitment to quality control.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation.

- Example: “Tell me about a time you faced a challenge while assembling an appliance.”

- Example: “Why are you interested in the Appliance Assembler position at our company?”

4. Dress Professionally and Bring a Resume

First impressions matter. Dress appropriately for the interview and bring copies of your resume and other relevant materials.

- Consider wearing business attire or smart casual clothing.

- Organize your resume and highlight your most relevant qualifications.

5. Show Enthusiasm and Confidence

Demonstrate your passion for appliance assembly and eagerness to contribute to the team.

- Express your interest in the industry and the company’s mission.

- Maintain eye contact and speak confidently about your abilities.

- Ask thoughtful questions to show your engagement and enthusiasm for the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Appliance Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.