Are you gearing up for an interview for a Apprentice Instrument Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Apprentice Instrument Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

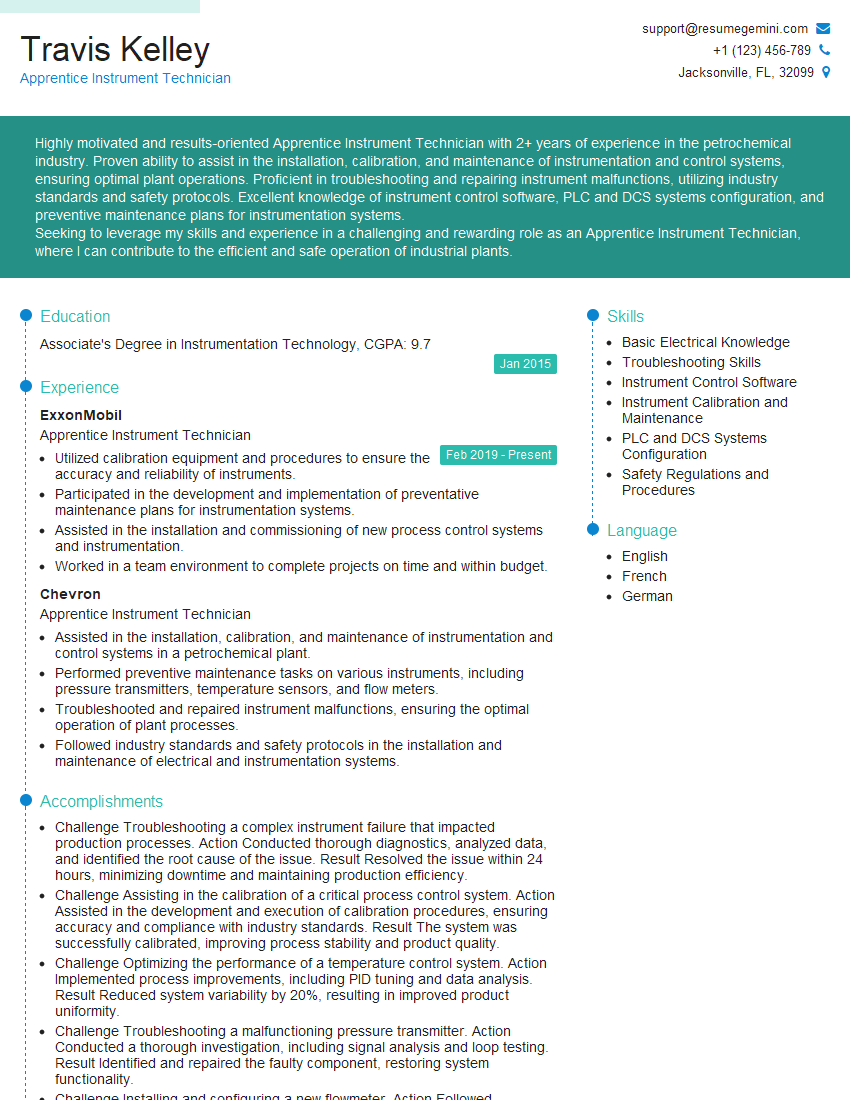

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Apprentice Instrument Technician

1. Describe the steps involved in calibrating a pressure transmitter.

- Connect the transmitter to a pressure source.

- Apply a known pressure to the transmitter.

- Read the output signal from the transmitter.

- Compare the output signal to the expected value.

- Adjust the transmitter’s calibration if necessary.

2. What are the different types of flow meters?

Turbine flow meters

- Measure the flow rate of a liquid or gas by measuring the speed of a rotating turbine.

Vortex shedding flow meters

- Measure the flow rate of a liquid or gas by measuring the frequency of vortices shed by a bluff body in the flow.

Ultrasonic flow meters

- Measure the flow rate of a liquid or gas by measuring the time it takes for an ultrasonic pulse to travel through the fluid.

3. How do you troubleshoot a temperature transmitter?

- Check the power supply to the transmitter.

- Check the input signal to the transmitter.

- Check the output signal from the transmitter.

- Check the calibration of the transmitter.

4. What are the different types of control valves?

- Globe valves

- Ball valves

- Butterfly valves

- Diaphragm valves

- Pinch valves

5. How do you size a control valve?

- Determine the flow rate of the fluid.

- Determine the pressure drop across the valve.

- Select a valve with a Cv that is greater than the required flow rate.

6. What are the different types of control loops?

- Open loop control

- Closed loop control

- Feedback control

- Feedforward control

7. How do you tune a PID controller?

- Set the proportional gain (Kp) to zero.

- Increase the integral gain (Ki) until the output signal starts to oscillate.

- Decrease the Ki until the oscillations stop.

- Set the derivative gain (Kd) to zero.

- Increase the Kd until the output signal responds more quickly to changes in the input signal.

8. What are the different types of safety instrumented systems (SIS)?

- Basic safety instrumented systems (BSIS)

- Safety instrumented systems (SIS)

- High integrity safety instrumented systems (HISIS)

9. How do you design a SIS?

- Define the safety instrumented function (SIF).

- Select the safety integrity level (SIL) for the SIF.

- Design the SIS architecture.

- Select the SIS components.

- Verify and validate the SIS.

10. What are the different types of safety devices?

- Pressure relief valves

- Temperature relief valves

- Flow restrictors

- Rupture disks

- Flame arrestors

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Apprentice Instrument Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Apprentice Instrument Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Apprentice Instrument Technicians assist in the maintenance and repair of industrial instrumentation and control systems. They perform a variety of tasks, including:

1. Installation and Maintenance

Installing and maintaining instruments such as pressure gauges, flow meters, and temperature sensors.

- Following blueprints and schematics to install new equipment.

- Maintaining and repairing existing equipment to ensure proper operation.

2. Troubleshooting and Repair

Troubleshooting and repairing instrument and control systems.

- Identifying and diagnosing faults in systems.

- Repairing or replacing faulty components.

3. Calibration and Testing

Calibrating and testing instruments and control systems to ensure accuracy.

- Using specialized equipment to calibrate instruments.

- Testing systems to ensure they are operating within specifications.

4. Documentation and Record Keeping

Documenting and maintaining records of instrument maintenance and repair.

- Creating and maintaining work orders.

- Recording data on instrument performance and repairs.

Interview Tips

Preparing for an interview can be nerve-racking, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview for an Apprentice Instrument Technician position:

1. Research the Company and Position

Take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in an Apprentice Instrument Technician.

- Visit the company’s website to learn about their history, mission, and products/services.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Once you have a good understanding of the company and position, start practicing your answers to common interview questions. This will help you feel more confident and prepared during the actual interview.

- Think about your strengths and weaknesses as they relate to the position.

- Prepare examples of your work experience and skills that demonstrate your qualifications.

3. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are taking the interview seriously.

- Choose clothing that is clean, pressed, and appropriate for an office setting.

- Arrive at the interview location at least 15 minutes early to give yourself time to check in and relax.

4. Be Yourself and Be Enthusiastic

It is important to be yourself during the interview and to show the interviewer your enthusiasm for the position. This will help you connect with the interviewer and make a lasting impression.

- Be honest about your skills and experience, and don’t try to be someone you’re not.

- Show the interviewer that you are passionate about the position and that you are eager to learn and grow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Apprentice Instrument Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.