Feeling lost in a sea of interview questions? Landed that dream interview for Arc and Gas Welder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Arc and Gas Welder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

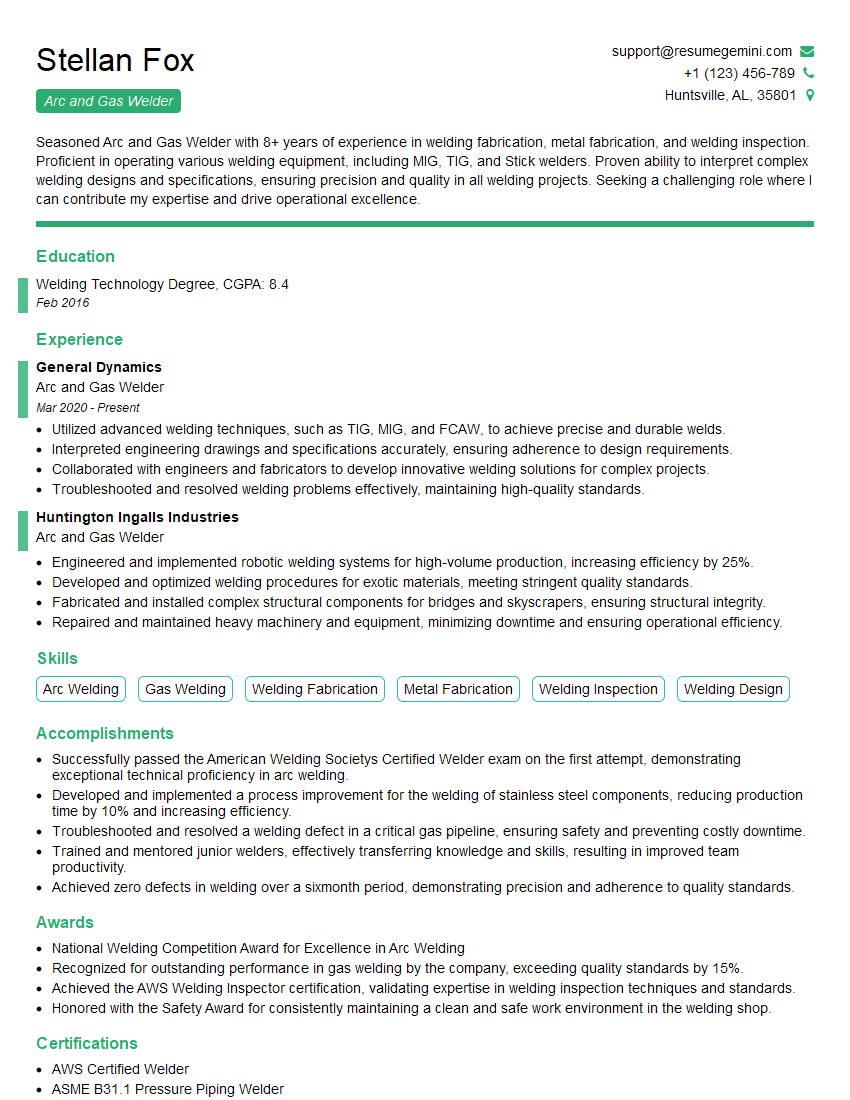

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Arc and Gas Welder

1. What are the key differences between arc welding and gas welding?

- Arc welding uses an electric arc to melt the metal, while gas welding uses a flame.

- Arc welding is more versatile and can be used to weld a wider variety of metals, while gas welding is better suited for welding thin metals.

- Arc welding is faster than gas welding, but it can also be more difficult to control.

2. What are the different types of arc welding?

Shielded metal arc welding (SMAW)

- Also known as stick welding, SMAW is a manual arc welding process that uses a consumable electrode.

- The electrode is coated with a flux that shields the weld from the atmosphere and produces a slag that protects the weld from oxidation.

Gas metal arc welding (GMAW)

- Also known as MIG welding, GMAW is a semi-automatic or automatic arc welding process that uses a continuous solid wire electrode.

- The electrode is fed through a welding gun and a shielding gas is used to protect the weld from the atmosphere.

Gas tungsten arc welding (GTAW)

- Also known as TIG welding, GTAW is a manual arc welding process that uses a non-consumable tungsten electrode.

- The electrode is held in a welding torch and a shielding gas is used to protect the weld from the atmosphere.

3. What are the different types of gas welding?

- Oxy-acetylene welding (OAW) is a gas welding process that uses oxygen and acetylene gases to produce a flame.

- OAW is used to weld a wide variety of metals, including steel, stainless steel, and aluminum.

- Other gas welding processes include oxy-hydrogen welding (OHW), oxy-propane welding (OPW), and air-acetylene welding (AAW).

4. What are the advantages and disadvantages of arc welding?

Advantages

- Versatile and can be used to weld a wide variety of metals

- Fast

- Produces strong welds

Disadvantages

- Can be difficult to control

- Can produce fumes and sparks

- Requires specialized equipment

5. What are the advantages and disadvantages of gas welding?

Advantages

- Easy to control

- Produces clean welds

- Does not require specialized equipment

Disadvantages

- Slower than arc welding

- Cannot be used to weld all metals

- Can produce fumes and sparks

6. What are the safety precautions that should be taken when arc welding?

- Wear appropriate protective clothing, including a welding helmet, gloves, and apron.

- Ensure that the work area is well-ventilated.

- Do not weld near flammable materials.

- Be aware of the potential for electrical shock.

7. What are the safety precautions that should be taken when gas welding?

- Wear appropriate protective clothing, including a welding helmet, gloves, and apron.

- Ensure that the work area is well-ventilated.

- Do not weld near flammable materials.

- Be aware of the potential for burns.

8. What are the common defects that can occur in arc welds?

- Porosity

- Cracking

- Undercutting

- Overlapping

- Cold lap

9. What are the common defects that can occur in gas welds?

- Porosity

- Cracking

- Undercutting

- Overlapping

- Cold lap

- Burn-through

10. How do you inspect arc welds?

- Visual inspection

- Radiographic inspection

- Ultrasonic inspection

- Magnetic particle inspection

- Dye penetrant inspection

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Arc and Gas Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Arc and Gas Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Arc and Gas Welders play a crucial role in various industries, using specialized techniques to join metal components. Key responsibilities include:

1. Welding Operations

Plan and execute welding tasks based on blueprints, specifications, and safety protocols.

- Select appropriate welding equipment and consumables.

- Prepare and assemble workpieces for welding.

- Apply different welding methods (e.g., arc welding, gas welding).

2. Inspection and Quality Assurance

Inspect welds for defects or imperfections.

- Ensure welds conform to industry standards.

- Conduct non-destructive testing to verify weld integrity.

- Maintain accurate work records and documentation.

3. Equipment Maintenance and Safety

Maintain welding equipment in good working order.

- Perform regular inspections and repairs.

- Follow safety regulations and guidelines.

- Handle welding materials and chemicals with care.

4. Communication and Collaboration

Communicate effectively with supervisors, co-workers, and clients.

- Discuss welding requirements and specifications.

- Resolve issues and provide technical guidance.

- Contribute to team projects and meet deadlines.

Interview Tips

To ace the interview, consider these tips:

1. Research the Company and Industry

Learn about the company’s operations, background, and industry trends.

- Visit the company website and social media pages.

- Read industry publications and news articles.

2. Prepare for Technical Questions

Anticipate questions about welding techniques, materials, and equipment.

- Review basic welding principles and different welding methods.

- Familiarize yourself with welding codes and standards.

3. Showcase Your Skills and Experience

Highlight your welding skills, certifications, and relevant work experiences.

- Provide specific examples of successful welding projects.

- Discuss your ability to solve welding-related problems.

4. Emphasize Safety and Quality

Stress your commitment to safety and maintaining high-quality standards.

- Mention safety procedures you follow and any certifications you hold.

- Explain your approach to ensuring weld integrity and meeting customer specifications.

5. Dress Professionally and Be Punctual

Make a positive first impression by dressing professionally and arriving on time.

- Consider wearing flame-resistant clothing.

- Bring a portfolio or samples of your work if applicable.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Arc and Gas Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.