Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

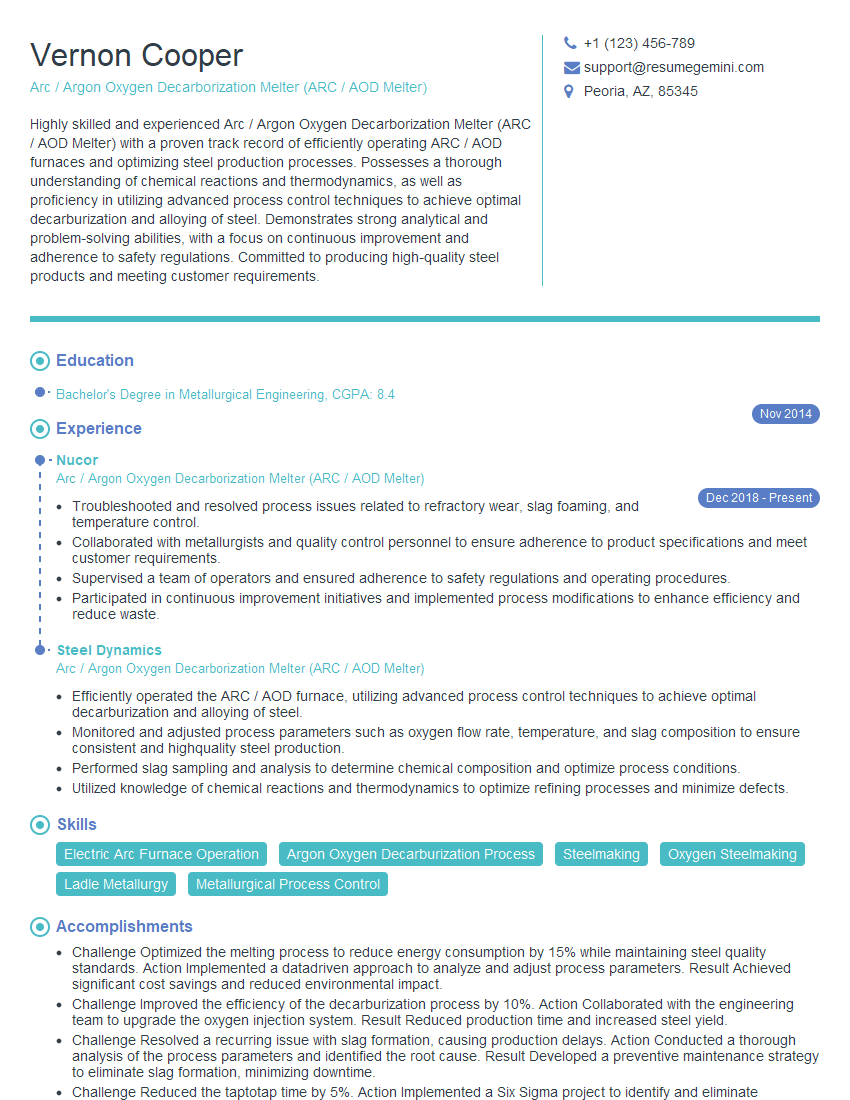

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter)

1. What is the purpose of an Argon Oxygen Decarborization (AOD) process?

The AOD process is used to refine molten steel by removing carbon and other impurities through the injection of oxygen and argon gas. It helps improve the steel’s cleanliness, strength, and other properties.

2. Describe the key components of an AOD vessel and their functions.

Vessel Body:

- Holds the molten steel during the refining process.

- Lined with refractory bricks to withstand high temperatures.

Oxygen Lance:

- Injects pure oxygen into the molten steel to promote oxidation.

- Cooled to prevent damage from high temperatures.

Argon Lance:

- Injects argon gas to agitate the molten steel and improve mixing.

- Protects the oxygen lance and vessel lining from excessive heat.

3. What are the main process steps involved in the AOD process?

- Charging of molten steel into the AOD vessel.

- Injection of oxygen and argon gases to refine the steel.

- Liming and other alloy additions to adjust the steel’s composition.

- Tapping of the refined steel into a ladle.

4. How do you control the carbon content in the AOD process?

- Monitoring the carbon levels through chemical analysis.

- Adjusting the oxygen injection rate based on the desired carbon target.

- Using lime additions to form calcium carbide and remove carbon from the steel.

5. What safety precautions are essential during the operation of an AOD vessel?

- Proper ventilation to prevent exposure to harmful gases.

- Use of protective clothing and equipment, such as helmets, gloves, and fire-resistant suits.

- Adherence to established operating procedures and safety protocols.

6. How do you troubleshoot common problems that may occur during the AOD process?

- Oxygen lance blockages: Check gas flow, replace lance if necessary.

- Excessive foaming: Reduce oxygen flow rate, add anti-foaming agents.

- Incomplete decarburization: Increase oxygen flow rate, adjust lime additions.

7. Explain the role of slag in the AOD process and how it is managed.

Slag is a molten mixture of oxides and impurities that form on top of the molten steel. It absorbs impurities and protects the vessel lining. Slag management involves controlling its thickness, composition, and removal to ensure optimal refining conditions.

8. What are the advantages of using an AOD process compared to other steel refining methods?

- Improved steel cleanliness and reduced inclusion content.

- Enhanced control over steel composition and properties.

- Increased productivity and efficiency.

9. Describe the instrumentation and control systems used in the operation of an AOD vessel.

- Temperature sensors to monitor steel and slag temperatures.

- Gas flow meters to control oxygen and argon injection rates.

- Chemical analyzers to determine steel composition and carbon levels.

10. What are the key performance indicators (KPIs) used to evaluate the efficiency and effectiveness of the AOD process?

- Steel yield and recovery rate.

- Carbon removal efficiency.

- Oxygen consumption and lance life.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Arc / Argon Oxygen Decarborization (AOD) Melter is responsible for operating and maintaining the Arc and Argon Oxygen Decarborization (AOD) furnace, which is used to refine steel. Key responsibilities include:

1. Furnace Operation

Operate the electric arc furnace (EAF) to melt scrap metal and control the temperature and composition of the molten steel.

- Monitor and adjust furnace parameters, such as power, voltage, and oxygen flow, to ensure optimal melting conditions.

- Tap the furnace to release the molten steel into the ladle.

2. Refining Process

Control the refining process in the AOD furnace, using oxygen and argon to remove impurities from the molten steel.

- Monitor and adjust the flow of oxygen and argon gases to optimize the refining process.

- Take samples of the molten steel to analyze the composition and determine the appropriate refining parameters.

- Collaborate with metallurgists and engineers to develop and implement refining procedures.

3. Equipment Maintenance

Inspect, troubleshoot, and repair the AOD furnace and related equipment to ensure proper operation and safety.

- Perform regular maintenance tasks, such as cleaning and relining the furnace.

- Identify and resolve equipment malfunctions and breakdowns.

- Coordinate with maintenance personnel to schedule and complete repairs.

4. Quality Assurance

Monitor the quality of the molten steel and ensure compliance with product specifications.

- Conduct quality control tests on the molten steel, including chemical analysis and mechanical testing.

- Maintain records of furnace operations and refining parameters for quality tracking and traceability.

- Collaborate with quality control personnel to investigate and resolve quality issues.

Interview Tips

Preparing for an interview as an Arc / Argon Oxygen Decarborization Melter requires a thorough understanding of the job responsibilities and industry knowledge. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Familiarize yourself with the specific steelmaking process and technologies used by the company you’re applying to. Research the company’s history, products, and market position.

- Visit the company’s website and read their annual reports.

- Attend industry events and conferences to network and learn about the latest advancements.

- Follow industry publications and trade journals.

2. Highlight Your Technical Skills

Demonstrate your proficiency in operating and maintaining electric arc furnaces and AOD furnaces. Emphasize your knowledge of refining processes, metallurgy, and quality control.

- Provide examples of your experience in troubleshooting and repairing furnace equipment.

- Discuss your understanding of the chemistry and physics involved in steelmaking.

- Highlight your ability to analyze data and make adjustments to optimize furnace performance.

3. Emphasize Safety and Quality

Safety and quality are paramount in the steelmaking industry. Show that you prioritize safety procedures and take pride in producing high-quality steel.

- Describe your adherence to safety regulations and protocols.

- Explain your understanding of the importance of quality control and traceability in steelmaking.

- Share examples of your contributions to improving safety and quality in previous roles.

4. Show Your Teamwork and Communication Skills

Working as an Arc / AOD Melter requires teamwork and effective communication. Highlight your ability to work collaboratively with colleagues and communicate clearly with management and customers.

- Provide examples of successful teamwork projects you have been involved in.

- Describe your experience in communicating technical information to non-technical stakeholders.

- Show your willingness to share your knowledge and expertise with others.

5. Be Prepared for Technical Questions

Anticipate technical questions related to steelmaking processes, furnace operations, and quality control. Practice answering these questions concisely and demonstrate your in-depth understanding of the subject matter.

- Review basic metallurgy concepts and the principles of electric arc furnace and AOD refining.

- Prepare for questions about slag management, temperature control, and alloying practices.

- Be ready to discuss your experience with specific furnace technologies and control systems.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter), it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Arc / Argon Oxygen Decarborization Melter (ARC / AOD Melter) positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.