Are you gearing up for an interview for a Arc Welder Apprentice position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Arc Welder Apprentice and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

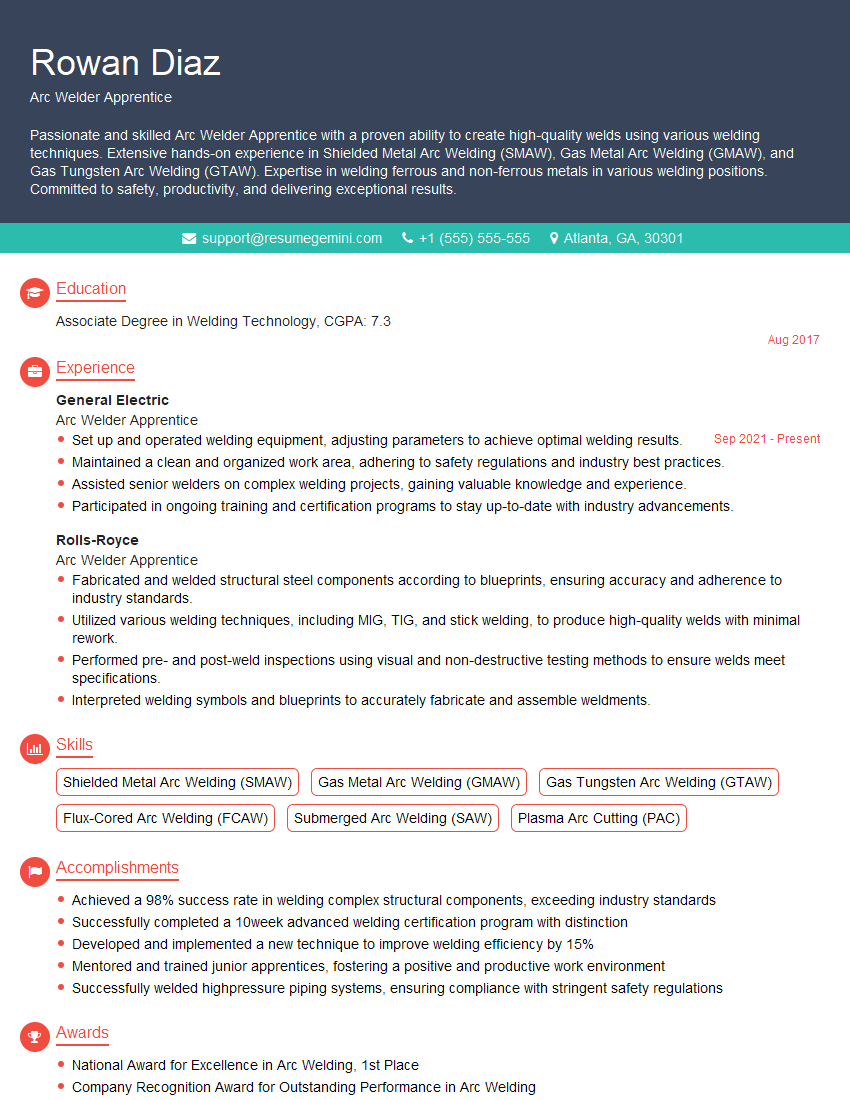

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Arc Welder Apprentice

1. Explain the process of shielded metal arc welding (SMAW).

SMAW, commonly known as stick welding, involves the following steps:

- Preparation: Clean and prepare the welding surfaces to remove impurities.

- Electrode Selection: Choose the appropriate electrode based on the metal types and thickness.

- Arc Striking: Strike the arc by touching the electrode to the metal surface and quickly pulling it back to establish an arc.

- Welding: Maintain the arc while moving the electrode along the joint, melting the base metal and depositing filler material from the electrode.

- Slag Removal: After welding, remove the slag (non-metallic impurities) that forms on the weld surface.

2. What are the different types of electrodes used in SMAW?

SMAW electrodes come in various types, including:

E60xx:

- General-purpose electrodes suitable for mild steel welding.

- Provide good penetration and bead appearance.

E70xx:

- High-strength electrodes for welding high-tensile steels.

- Offer superior strength and toughness.

E308xx:

- Stainless steel electrodes used for welding stainless steel materials.

- Resist corrosion and maintain the properties of the base metal.

3. Describe the safety precautions that should be taken while arc welding.

To ensure safety during arc welding, it is crucial to follow these precautions:

- Wear appropriate protective gear, including a welding helmet, gloves, and flame-resistant clothing.

- Ventilate the work area to remove welding fumes.

- Use proper grounding techniques to prevent electrical shock.

- Keep flammable materials away from the welding area.

- Inspect equipment regularly and maintain it in good condition.

4. What are the key factors that affect weld quality?

Weld quality is influenced by various factors, including:

- Joint preparation: Proper joint preparation ensures good weld penetration and fusion.

- Welding technique: Skilled welding techniques, such as maintaining proper arc length and travel speed, contribute to high-quality welds.

- Base metal properties: The chemical composition and thickness of the base metal affect the weldability and strength.

- Welding parameters: Adjusting welding parameters, such as current, voltage, and polarity, can optimize weld quality.

- Post-weld treatments: Heat treatment or stress relief processes can enhance weld properties.

5. How do you inspect a weld for defects?

To inspect a weld for defects, the following methods can be used:

- Visual inspection: Examine the weld surface for cracks, porosity, undercut, and other visible defects.

- Non-destructive testing (NDT) methods:

- Radiographic testing (RT): Uses X-rays or gamma rays to detect internal flaws.

- Ultrasonic testing (UT): Utilizes sound waves to identify defects below the surface.

- Destructive testing: Involves cutting or breaking the weld to analyze its internal structure and properties.

6. What are the different welding positions?

Arc welding can be performed in various positions, including:

- Flat position: Welding on a horizontal surface.

- Horizontal position: Welding on a vertical surface.

- Vertical position: Welding on a vertical surface with the weld moving upwards.

- Overhead position: Welding on a ceiling or overhead surface.

7. How do you set up and calibrate a welding machine?

Setting up and calibrating a welding machine involves the following steps:

- Connect the machine to the appropriate power source.

- Select the desired welding process and parameters (e.g., current, voltage, polarity).

- Calibrate the welding wire feed speed to match the welding current.

- Adjust the shielding gas flow rate to provide adequate protection for the weld.

- Test the machine on scrap material to ensure proper operation and fine-tune the settings as needed.

8. What are the different types of welding joints?

Common types of welding joints include:

- Butt joint: Joining two pieces of metal end-to-end.

- Edge joint: Joining two pieces of metal side-by-side.

- Tee joint: Joining a perpendicular piece of metal to a flat surface.

- Lap joint: Overlapping two pieces of metal.

- Corner joint: Joining two pieces of metal at a 90-degree angle.

9. How do you calculate the proper welding amperage for a given material thickness?

The proper welding amperage can be calculated using the following formula:

- Amperage = (Material Thickness in inches) x 100

For example, to weld a material that is 1/4 inch thick, the recommended amperage would be 1/4 inch x 100 = 25 amps.

10. What is the difference between a MIG welder and a TIG welder?

MIG (Metal Inert Gas) welding uses a continuously fed solid wire electrode with an inert shielding gas to create the weld, while TIG (Tungsten Inert Gas) welding uses a non-consumable tungsten electrode with an inert shielding gas to form the weld.

- MIG welding is typically faster and more efficient than TIG welding.

- TIG welding provides greater precision and control, resulting in higher-quality welds.

- MIG welding is suitable for thicker materials, while TIG welding is often used for thin materials and intricate welds.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Arc Welder Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Arc Welder Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Arc Welder Apprentices work under the supervision of experienced welders to learn the trade. They assist with welding tasks and perform other duties as assigned. Specific responsibilities may include:1. Assisting with Welding Tasks

- Loading and unloading welding equipment

- Preparing and cleaning welding surfaces

- Setting up and operating welding machines

- Performing welding operations under supervision

- Inspecting welds for quality and accuracy

2. Learning Welding Techniques

- Observing and assisting experienced welders

- Studying welding manuals and textbooks

- Practicing welding techniques under supervision

- Passing welding certification tests

3. Maintaining Work Area

- Keeping work area clean and organized

- Maintaining welding equipment and tools

- Following safety procedures

- Disposing of welding waste properly

4. Other Duties

- Assisting with non-welding tasks as needed

- Providing support to other employees

- Maintaining a positive and professional attitude

- Advancing knowledge and skills through continuing education

Interview Tips

Preparing for an interview can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are some tips to help you ace your interview for an Arc Welder Apprentice position:1. Research the Company

- Visit the company’s website to learn about their products, services, and culture.

- Read industry news and articles to stay up-to-date on the latest welding trends and technologies.

- Network with people who work in the welding industry to gain insights into the company and the position.

2. Practice Your Welding Skills

- If possible, practice welding before the interview so that you can demonstrate your skills to the hiring manager.

- Bring examples of your welding work to the interview so that the hiring manager can see your craftsmanship.

- Be prepared to answer questions about your welding skills and experience.

3. Dress Professionally

- First impressions matter, so dress professionally for your interview.

- Wear clean, pressed clothing that is appropriate for a work environment.

- Avoid wearing jewelry or clothing that could get caught in welding equipment.

4. Be Enthusiastic and Positive

- Show the hiring manager that you are enthusiastic about the welding trade and that you are eager to learn.

- Be positive and upbeat throughout the interview.

- Highlight your passion for welding and your willingness to work hard.

5. Ask Questions

- Asking questions shows that you are interested in the position and the company.

- Prepare a few questions to ask the hiring manager about the apprenticeship program, the company’s culture, and the future of the welding industry.

- Be prepared to answer questions about yourself, your skills, and your experience.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Arc Welder Apprentice interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!