Are you gearing up for an interview for a Arc Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Arc Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

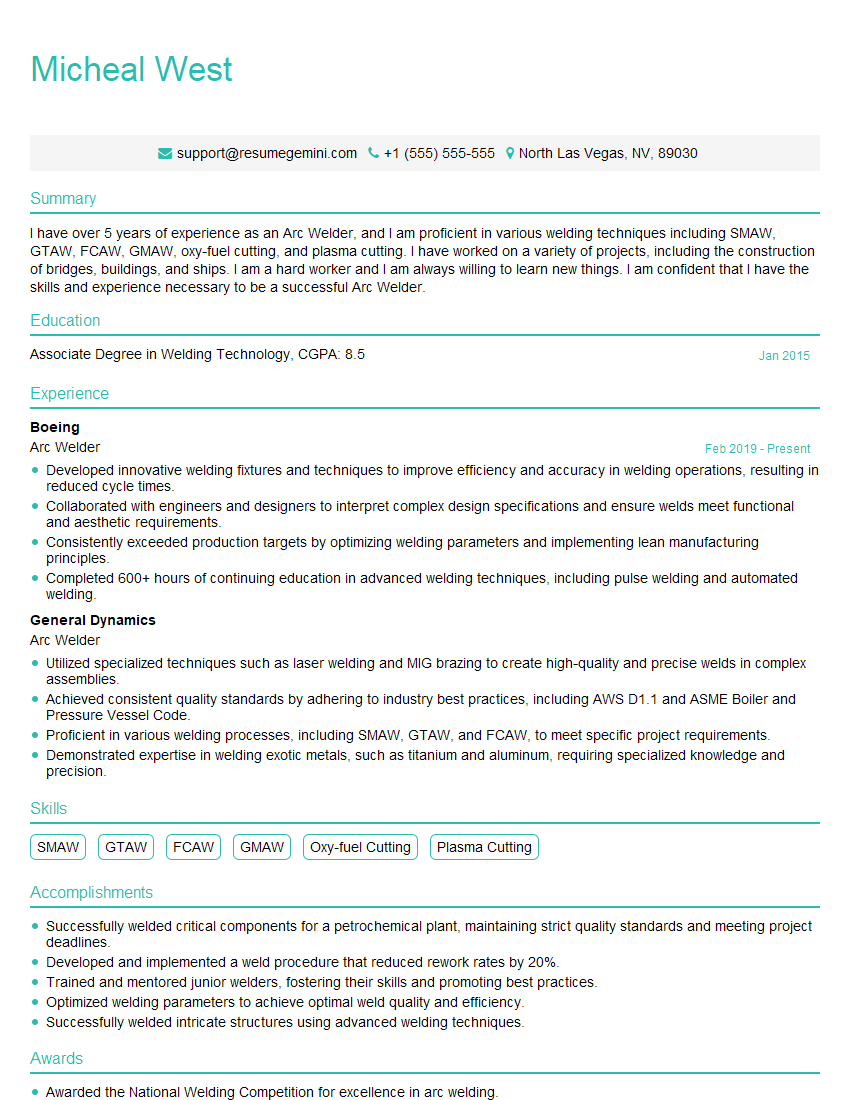

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Arc Welder

1. Describe the different welding processes you are familiar with, and explain the applications of each?

- Shielded Metal Arc Welding (SMAW) – Also known as “stick welding,” SMAW uses a consumable electrode covered in flux to create an arc and deposit molten metal. It is commonly used in construction, shipbuilding, and repair work.

- Gas Metal Arc Welding (GMAW) – Also known as “MIG welding,” GMAW uses a continuous wire electrode and a shielding gas to create an arc and deposit molten metal. It is widely used in automotive, manufacturing, and fabrication industries.

- Gas Tungsten Arc Welding (GTAW) – Also known as “TIG welding,” GTAW uses a non-consumable tungsten electrode and a shielding gas to create an arc and deposit molten metal. It provides high-quality welds and is often used in aerospace, medical equipment, and food processing industries.

- Flux-Cored Arc Welding (FCAW) – FCAW uses a tubular wire electrode filled with flux, which provides both shielding and alloying elements. It is a versatile process suitable for a wide range of applications, including construction, shipbuilding, and heavy machinery manufacturing.

2. What are the key factors that influence the quality of a welded joint?

- Joint Preparation: Proper fit-up, edge preparation, and surface cleanliness are crucial for creating a strong and durable joint.

- Welding Parameters: Voltage, amperage, travel speed, and gas flow rate must be carefully controlled to ensure optimal weld quality.

- Electrode Selection: Choosing the right electrode material and size is essential for achieving the desired weld properties.

- Welding Technique: Proper electrode manipulation, angle, and travel technique are critical for laying down a sound weld.

3. How do you ensure the safety of yourself and others during welding operations?

- Personal Protective Equipment (PPE): Wearing appropriate PPE, such as a welding helmet, gloves, and protective clothing, is essential.

- Ventilation: Proper ventilation should be in place to remove welding fumes and gases.

- Fire Safety: Have fire extinguishers and blankets readily available, and follow safe procedures for handling hot work.

- Electrical Safety: Inspect equipment regularly, ensure proper grounding, and isolate the work area from electrical hazards.

4. How do you inspect and test welded joints to ensure their integrity?

- Visual Inspection: Examining the weld for defects such as cracks, porosity, or undercuts using a magnifying glass.

- Non-Destructive Testing (NDT): Using techniques such as radiography, ultrasonic testing, or magnetic particle inspection to detect internal flaws.

- Destructive Testing: Performing destructive tests, such as bend tests or tensile tests, to assess the mechanical properties of the weld joint.

5. What is your experience with welding different types of metals?

- Mild Steel: I have extensive experience welding mild steel in various thicknesses, using different welding processes.

- Stainless Steel: I have welded stainless steel for food processing equipment, laboratory components, and architectural applications.

- Aluminum: I have experience welding aluminum for aerospace, automotive, and marine industries, using both GTAW and GMAW.

- Titanium: I have specialized training in welding titanium for medical implants and aerospace components.

6. How do you handle working in confined spaces or on elevated structures?

- Confined Spaces: I follow all safety protocols, including using appropriate ventilation and personal protective equipment.

- Elevated Structures: I am comfortable working at heights, have experience with proper fall protection measures, and follow all safety guidelines.

7. What welding codes and standards are you familiar with?

- American Welding Society (AWS) D1.1: Structural Welding Code – Steel

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC) Section IX: Welding Qualification and Performance

- National Fire Protection Association (NFPA) 51B: Standard for Fire Prevention During Welding, Cutting, and Other Hot Work

8. Describe your experience with welding automation and robotics.

- Welding Automation: I have experience setting up and operating automated welding systems, including robotic welders and welding positioners.

- Welding Robotics: I have programmed and operated welding robots to perform complex welding tasks with high accuracy and repeatability.

9. What is your understanding of welding metallurgy and how it affects the properties of welded joints?

- Metal Properties: I understand the composition, microstructure, and mechanical properties of different metals and how they change during welding.

- Heat Treatment: I know how heat treatment can be used to alter the properties of welded joints, such as improving strength and toughness.

10. How do you stay updated with advancements in welding technology and practices?

- Training and Certifications: I attend industry workshops, seminars, and conferences to stay informed about new techniques and best practices.

- Industry Publications: I subscribe to welding trade magazines and journals to stay abreast of industry trends and research.

- Professional Organizations: I am a member of the American Welding Society (AWS) and actively participate in chapter meetings and events.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Arc Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Arc Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Arc welders are responsible for joining metal parts together using an electric arc. They use a variety of welding techniques, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW). Arc welders must be able to read and interpret blueprints and welding symbols, and they must have a strong understanding of the welding process. They must also be able to work independently and as part of a team.Some of the key job responsibilities of an arc welder include:

1. Preparing the welding area

This involves cleaning the metal surfaces to be welded, and setting up the welding equipment.

- Inspecting metal surfaces to be welded for defects or impurities.

- Marking welding points according to blueprints or specifications.

- Positioning and securing metal parts in preparation for welding.

2. Operating welding equipment

This involves using a variety of welding techniques to join metal parts together.

- Setting up welding equipment, including selecting the appropriate welding process, welding parameters, and shielding gas.

- Initiating and maintaining the welding arc to fuse metal parts together.

- Adjusting welding parameters to ensure a strong and durable weld.

3. Inspecting welds

This involves checking the quality of the welds to ensure that they meet the required standards.

- Visually inspecting welds for defects such as cracks, porosity, and undercuts.

- Using non-destructive testing methods to evaluate weld quality, such as radiography or ultrasonic testing.

- Repairing or rewelding defective welds to ensure they meet specifications.

4. Maintaining welding equipment

This involves keeping the welding equipment in good working order to ensure efficient and safe operation.

- Cleaning and inspecting welding equipment regularly to identify and address any potential issues.

- Performing routine maintenance tasks, such as replacing welding tips and cleaning welding torches.

- Troubleshooting and repairing welding equipment when necessary.

Interview Tips

Here are some interview tips to help you ace the interview for an arc welder position:

1. Research the company and the position

Take some time to learn about the company you’re applying to, as well as the specific position you’re interested in. This will help you answer questions about your qualifications and why you’re interested in the job.

- Visit the company’s website to learn about their history, mission, and values.

- Read online reviews of the company to get a sense of what it’s like to work there.

- Search for news articles about the company to learn about their recent projects and accomplishments.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions and practice saying them aloud.

- Ask a friend or family member to mock interview you so that you can get feedback on your answers.

- Use the STAR method to answer interview questions. The STAR method stands for Situation, Task, Action, Result. When answering a question, start by describing the situation you were in, the task you had to complete, the actions you took, and the results of your actions.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the position and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for an office setting.

- Arrive at the interview location 10-15 minutes early so that you have time to relax and collect your thoughts.

- If you’re running late, be sure to call or email the interviewer to let them know.

4. Be confident and enthusiastic

Confidence is key in any interview, but it’s especially important in an interview for a welding position. Welders need to be confident in their abilities and in their ability to work safely and efficiently.

- Make eye contact with the interviewer and speak clearly and confidently.

- Use positive body language, such as sitting up straight and smiling.

- Be enthusiastic about the welding profession and about the position you’re applying for.

5. Follow up after the interview

After the interview, be sure to follow up with the interviewer to thank them for their time and to reiterate your interest in the position. You can also use this opportunity to ask any additional questions you may have about the position or the company.

- Send a thank-you email to the interviewer within 24 hours of the interview.

- In your email, thank the interviewer for their time and reiterate your interest in the position.

- You can also use this opportunity to ask any additional questions you may have about the position or the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Arc Welder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.