Feeling lost in a sea of interview questions? Landed that dream interview for Arm Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Arm Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

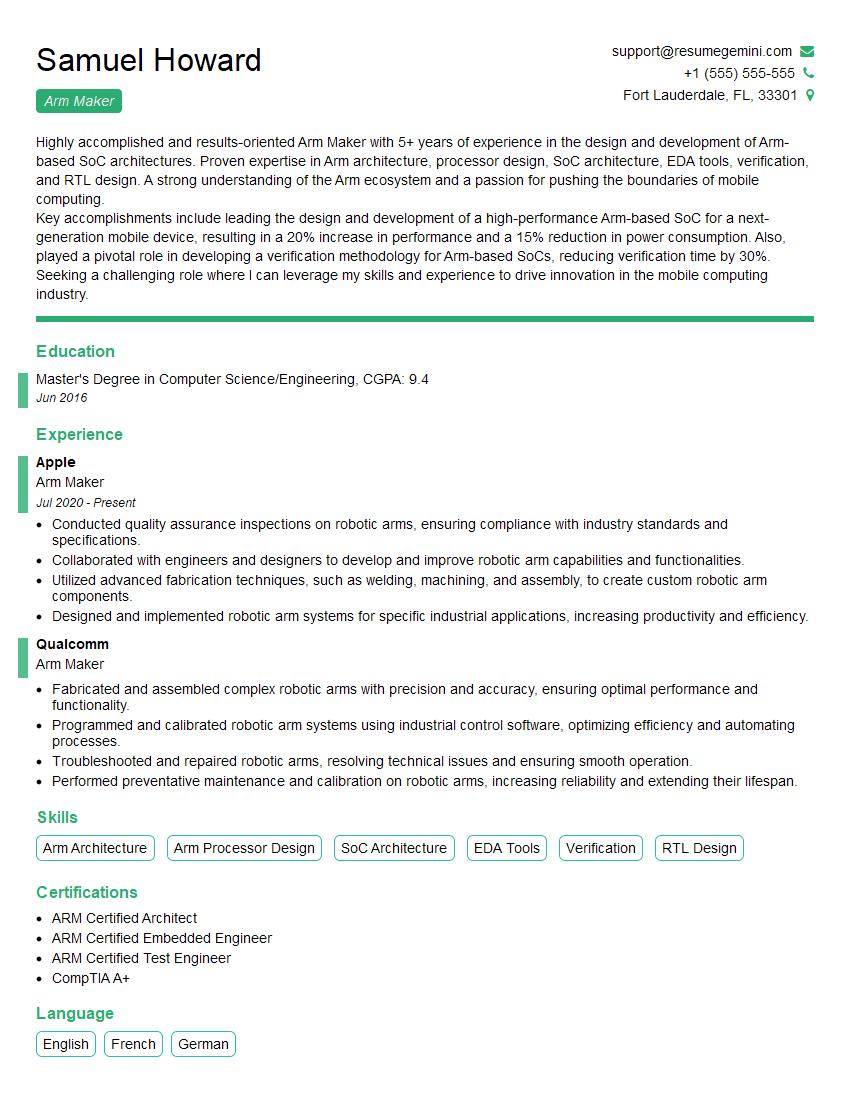

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Arm Maker

1. What are the different types of Arm processors and their respective use cases?

- Cortex-A series: These are high-performance processors designed for smartphones, tablets, and other mobile devices.

- Cortex-M series: These are low-power processors designed for embedded systems, such as microcontrollers and sensors.

- Cortex-R series: These are real-time processors designed for applications that require deterministic performance, such as industrial automation and medical devices.

2. Explain the concept of memory management in Arm processors.

Memory Protection Unit (MPU)

- Protects memory regions from unauthorized access

- Defines read, write, and execute permissions for each region

Memory Management Unit (MMU)

- Translates virtual memory addresses to physical memory addresses

- Enables efficient use of memory and supports multitasking

3. Describe the role of the instruction pipeline in Arm processors.

- Fetches instructions from memory

- Decodes instructions

- Executes instructions

- Improves performance by overlapping these stages

4. Explain the difference between Armv7 and Armv8 architectures.

- Instruction set: Armv8 introduces new instructions, such as AArch64, which support 64-bit computing.

- Memory management: Armv8 provides improved memory management features, such as virtualization and large physical address space (LPAS).

- Security: Armv8 includes security enhancements, such as TrustZone and pointer authentication.

5. What are the key considerations when designing Arm-based embedded systems?

- Power consumption

- Performance

- Cost

- Size

- Reliability

6. Describe the process of developing and debugging embedded software for Arm processors.

- Write code using an IDE or text editor

- Compile code using an Arm compiler

- Debug code using a debugger, such as GDB

- Load code onto the target device using a programmer

- Test and debug code on the target device

7. What are the common optimization techniques used for Arm assembly code?

- Register allocation

- Instruction scheduling

- Loop optimization

- Branch optimization

- Data alignment

8. Explain the concept of interrupt handling in Arm processors.

- Interrupts are external or internal events that cause the processor to suspend its current execution and jump to a specific interrupt service routine (ISR).

- Arm processors support multiple interrupt sources, each with a unique priority level.

- When an interrupt occurs, the processor pushes the current program counter and other context information onto the stack and jumps to the ISR.

9. What are the different types of buses used in Arm-based embedded systems?

- AMBA AXI bus: A high-performance bus used for high-bandwidth applications.

- AMBA AHB bus: A medium-performance bus used for general-purpose applications.

- AMBA APB bus: A low-power bus used for low-bandwidth applications.

10. Describe the role of Real-Time Operating Systems (RTOS) in Arm-based embedded systems.

- Provide a multitasking environment

- Manage resources, such as memory and I/O devices

- Provide real-time capabilities, such as predictable execution times

- Simplify the development of complex embedded systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Arm Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Arm Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Arm Maker plays a vital role in creating and maintaining the physical infrastructure of an organization’s operations. Their primary responsibilities encompass a wide range of tasks related to industrial machinery and equipment.

1. Equipment Installation and Maintenance

Arm Makers are responsible for the installation and maintenance of various industrial machinery, including robots, automated systems, and production lines. They ensure that the equipment is functioning optimally and efficiently, minimizing downtime and optimizing productivity.

- Assemble, install, and configure industrial machinery and equipment.

- Conduct regular maintenance checks and repairs to prevent breakdowns and ensure smooth operation.

- Diagnose and troubleshoot equipment malfunctions and implement appropriate solutions.

2. Process Optimization

Arm Makers work closely with engineers and production managers to optimize industrial processes and improve efficiency. They analyze existing systems and implement improvements to enhance productivity, reduce costs, and ensure quality.

- Analyze production processes and identify areas for improvement.

- Implement automation solutions and equipment upgrades to streamline operations.

- Monitor production data and make adjustments to optimize production schedules and minimize waste.

3. Safety and Compliance

Arm Makers are responsible for ensuring that the work environment complies with safety regulations and industry standards. They maintain a safe and hazard-free workplace and ensure that all equipment is operated in accordance with safety protocols.

- Identify and assess potential hazards in the work environment.

- Implement safety procedures and train employees on proper equipment usage.

- Conduct regular safety inspections and audits to ensure compliance.

4. Training and Supervision

Arm Makers often provide training and supervision to other employees, ensuring that they have the necessary skills and knowledge to operate and maintain industrial equipment safely and efficiently.

- Provide training on equipment operation, maintenance, and safety procedures.

- Supervise team members and ensure adherence to established guidelines.

- Evaluate employee performance and provide feedback for improvement.

Interview Tips

To prepare for an Arm Maker interview, candidates should focus on showcasing their technical expertise, problem-solving abilities, and commitment to safety. Here are some specific tips to help you ace the interview:

1. Research the Company and Role

Take the time to research the company you’re applying to and the specific role of an Arm Maker within that organization. This will give you a good understanding of the company’s values, goals, and the key responsibilities you’ll be expected to fulfill.

2. Highlight Your Technical Skills

Be prepared to discuss your technical skills in detail. This includes your knowledge of industrial machinery, automation systems, and electrical components. You should also be able to demonstrate your ability to troubleshoot and repair equipment.

3. Showcase Your Problem-Solving Abilities

Arm Makers are often faced with complex problems that require creative solutions. In your interview, be prepared to provide examples of how you’ve used your problem-solving skills to resolve issues in a previous role.

4. Emphasize Safety

Safety is paramount in an Arm Maker role. Highlight your commitment to safety by discussing your experience with safety regulations and your ability to identify and mitigate potential hazards.

5. Practice Your Answers

Take the time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. Here are some sample questions to practice:

- Tell us about your experience with industrial machinery.

- Describe a time when you had to troubleshoot a complex equipment problem.

- How do you ensure that the work environment is safe and compliant with regulations?

- What are your strengths and weaknesses as an Arm Maker?

- Why are you interested in this role with our company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Arm Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!