Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Armature Bander position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

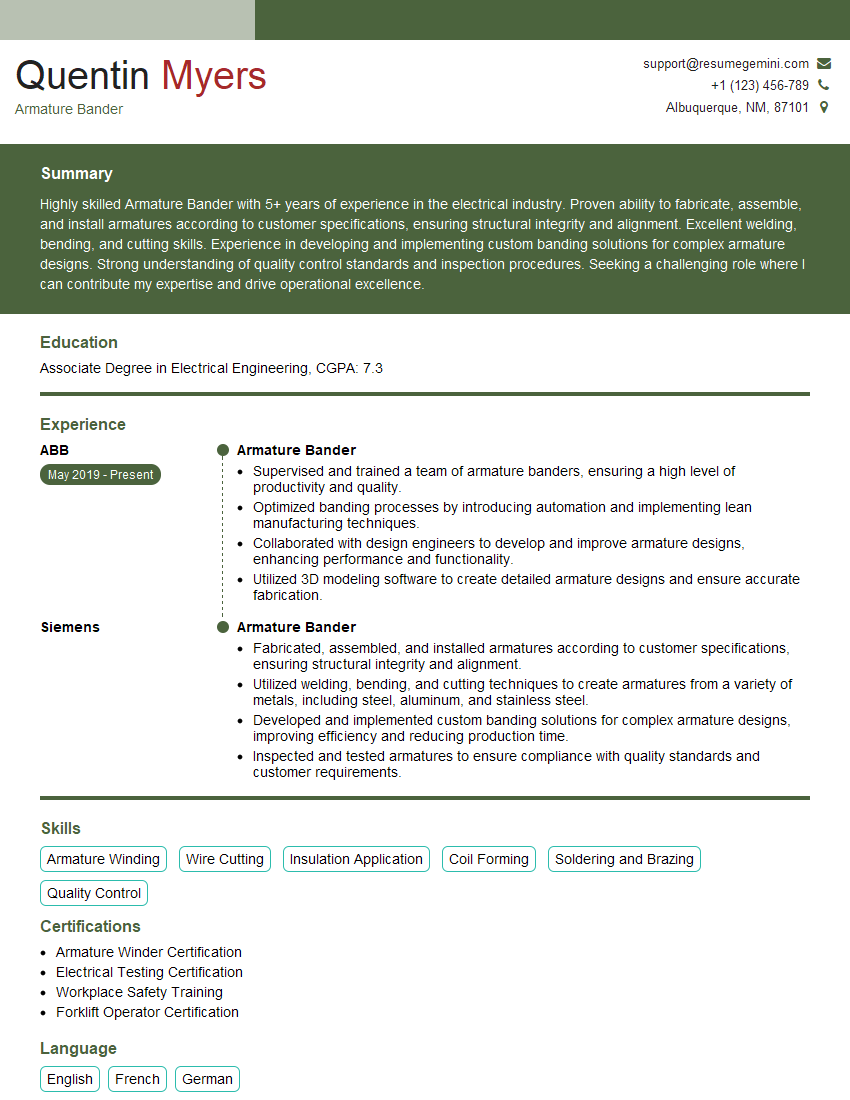

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Armature Bander

1. Describe the process of banding an armature?

The process of banding an armature involves several steps to secure the armature’s windings in place and ensure proper operation.

- Inspect the armature: Visually examine the armature for any damage or faults before banding.

- Prepare the banding materials: Select the appropriate banding materials, such as fiberglass or steel banding, based on the armature’s requirements.

- Position the banding: Place the banding material around the armature windings, ensuring proper alignment and tension.

- Tighten and secure the banding: Use banding tools, such as hand winders or tensioning devices, to tighten and secure the banding.

- Check the tension: Verify that the banding tension is uniform and within the specified range to ensure optimal armature performance.

2. What are the different types of banding materials used for armatures?

Fiberglass banding

- High tensile strength and insulation properties

- Resistant to heat and chemicals

- Suitable for high-speed motors and generators

Steel banding

- Very high strength and durability

- Can withstand extreme temperatures and mechanical stress

- Used for heavy-duty industrial applications

3. Explain the importance of proper tension when banding an armature?

Proper tension is crucial for the effective operation of the armature:

- Prevent loose windings: Excessive tension can cause the windings to loosen, leading to vibration, noise, and potential failure.

- Ensure electrical integrity: Adequate tension ensures proper contact between the windings and the armature core, maintaining electrical conductivity.

- Minimize stress on the windings: Optimal tension reduces mechanical stress on the windings, preventing damage and extending their lifespan.

4. Describe the tools and equipment used for armature banding?

- Banding tools: Manual or automated tools specifically designed for applying and tightening armature banding.

- Tensioning devices: Instruments used to measure and adjust the tension of the banding material.

- Cutters: Tools for cutting the banding material to the desired length.

- Safety gear: Protective gloves, eye protection, and appropriate clothing to ensure operator safety during banding operations.

5. What are the safety precautions to consider when banding an armature?

- Wear appropriate protective gear: Always use gloves, safety glasses, and appropriate clothing to protect against cuts, burns, and flying debris.

- Inspect tools and equipment: Ensure that all banding tools and equipment are in good working order and properly calibrated.

- Handle the armature carefully: Avoid touching the windings or core with bare hands to prevent electrical shock or damage.

- Follow manufacturer’s instructions: Adhere to the specific instructions provided by the armature manufacturer for proper banding techniques.

6. How do you troubleshoot a banding issue in an armature?

- Inspect the banding material: Check for any breaks, loose sections, or damage that may indicate improper tension or material failure.

- Verify the tension: Use a tensioning device to measure the tension of the banding and ensure it meets the specified range.

- Examine the armature windings: Inspect the windings for any signs of damage, such as loose connections, shorts, or insulation breakdown.

- Check the armature core: Look for any damage or deformation of the armature core that may have caused the banding issue.

7. Explain the different types of armatures and their applications?

Armatures vary in design and application depending on the intended use:

- Drum armatures: Used in motors and generators with rotating armatures, offering high torque and low speed.

- Lap armatures: Commonly found in traction motors and automotive starters, providing high starting torque and good speed regulation.

- Slotted armatures: Feature slots in the armature core to accommodate the windings, used in high-power motors and generators.

8. How do you calculate the banding tension for an armature?

- Determine the armature diameter: Measure the diameter of the armature core.

- Estimate the banding force: Calculate the required banding force based on the armature diameter and winding specifications.

- Select the banding material: Choose the appropriate banding material based on its tensile strength and the required banding force.

- Calculate the tension: Use the formula Tension = Banding Force / (2 x Banding Width)

9. Describe the process of balancing an armature?

- Mount the armature: Secure the armature on a balancing machine or fixture.

- Rotate the armature: Spin the armature at the desired speed to detect any imbalances.

- Identify the unbalanced areas: The balancing machine will indicate the location and amount of imbalance.

- Adjust the armature: Add or remove weight from the armature to correct the imbalance and achieve smooth rotation.

10. Explain the importance of armature banding for motor performance?

- Secure the windings: Armature banding holds the windings in place, preventing them from shifting or loosening during operation.

- Reduce vibration: Proper banding minimizes vibration caused by unbalanced windings, extending the lifespan of the motor.

- Enhance electrical efficiency: Secure windings ensure good electrical contact, reducing resistance and improving motor efficiency.

- Prevent overheating: Loose windings can cause excessive friction and heat buildup, which can damage the motor.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Armature Bander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Armature Bander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Armature Bander is responsible for performing essential tasks within the electrical construction industry. They handle the critical job of wrapping armature coil materials, ensuring the optimal performance and insulation of electrical machines.

Key responsibilities include:

1. Armature Preparation

- Inspect armature cores to ensure cleanliness and absence of defects

- Prep armature cores by cleaning, applying adhesives, and insulating as required

2. Material Handling

- Handle and store armature coil materials, including wire, insulation, and taping materials

- Maintain proper inventory levels and ensure materials meet specifications

3. Coil Winding and Banding

- Wind coils according to specifications, using manual or automated machines

- Apply banding materials to coils to secure and prevent damage

- Inspect and ensure proper tension and coverage of banding materials

4. Electrical Testing

- Conduct continuity and insulation tests on wound coils to verify accuracy

- Identify and rectify any electrical faults to ensure optimal performance

5. Quality Control

- Inspect completed armatures for defects, including improper winding, banding, or insulation

- Maintain records and documentation of quality control procedures

Interview Tips

To ace your interview as an Armature Bander, it’s crucial to prepare effectively. Here are some key tips:

1. Research the Company and Role

- Familiarize yourself with the specific industry, company culture, and job requirements

- This will help you understand the company’s expectations and tailor your answers accordingly

2. Practice Your Answers

- Prepare for common interview questions related to your skills, experience, and motivations

- Rehearse your answers in front of a mirror or with a friend for constructive feedback

3. Highlight Your Skills and Experience

- Emphasize your proficiency in armature winding, banding, and electrical testing

- Quantify your accomplishments and provide specific examples to demonstrate your abilities

4. Convey Your Passion

- Express your genuine interest in the electrical construction industry

- Share your knowledge and passion for armatures and electrical machines

5. Be Professional and Enthusiastic

- Dress professionally and arrive on time for your interview

- Maintain a positive attitude and show that you’re excited about the opportunity

By following these tips, you’ll be well-prepared to showcase your skills and enthusiasm, increasing your chances of success in the interview for the Armature Bander position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Armature Bander, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Armature Bander positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.