Feeling lost in a sea of interview questions? Landed that dream interview for Armature Connector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Armature Connector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

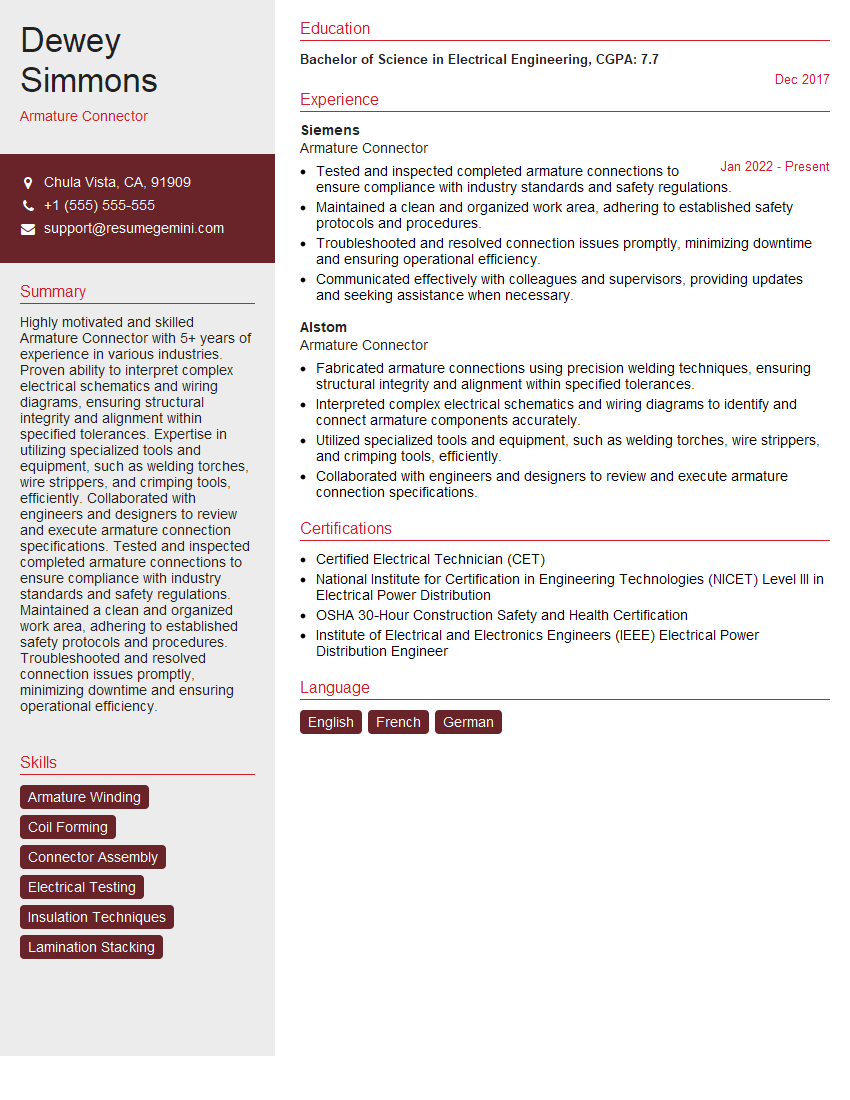

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Armature Connector

1. What are the primary functions of an armature connector?

An armature connector performs several crucial functions:

- Current transfer: It facilitates the flow of electric current from the commutator to the armature coils.

- Mechanical support: It provides mechanical support to the armature coils, preventing them from shifting or deforming.

- Electrical insulation: It insulates the coils from each other and from the armature core, preventing short circuits.

2. Describe the types of materials used in armature connector construction.

Conductor materials

- Copper: High electrical conductivity and low resistance

- Aluminum: Less expensive than copper, but higher resistance

Insulation materials

- Mica: Excellent electrical insulation and high heat resistance

- Fiber: Provides insulation and flexibility

- Resin: Acts as a binder and provides additional insulation

3. What factors should be considered when selecting an armature connector?

- Voltage rating: Connector must withstand the voltage of the armature circuit.

- Current rating: Connector must carry the current required by the armature coils.

- Mechanical strength: Connector must withstand the forces acting on the armature.

- Temperature resistance: Connector must operate reliably at the temperatures generated during armature operation.

4. Explain the process of installing armature connectors.

- Prepare the armature coils: Soldering terminals or tabs to the ends of the coils.

- Align the connectors: Position the connectors correctly on the armature slots.

- Solder or weld the connections: Securely connect the coils to the connectors.

- Insulate the connections: Apply insulating materials to prevent electrical shorts.

5. What are the common causes of armature connector failure?

- Overheating: Excessive current or poor ventilation can cause the connectors to overheat and melt.

- Vibration: Constant vibration can loosen the connections and lead to failure.

- Poor insulation: Inadequate or damaged insulation can cause short circuits.

- Mechanical stress: Excessive forces or impacts can damage the connectors.

6. What maintenance procedures are necessary for armature connectors?

- Regular inspections: Visually inspect the connectors for damage or loose connections.

- Cleaning: Remove any dirt or debris that could cause insulation breakdown.

- Tightening: Check and tighten loose connections to prevent arcing and overheating.

- Replacement: Replace damaged or worn-out connectors as needed.

7. What are the safety precautions to be observed when working with armature connectors?

- Electrical safety: Wear proper protective equipment and ensure the power is disconnected before working on the armature.

- Hot surfaces: Be aware that armature connectors can be hot during operation.

- Sharp edges: Handle the connectors carefully to avoid cuts or injuries.

- Proper tools: Use the correct tools and techniques to avoid damage to the connectors.

8. Describe the role of armature connectors in armature winding.

- Electrical connection: Provide electrical continuity between the armature coils.

- Mechanical support: Maintain the proper spacing between the coils and prevent coil deformation.

- Insulation: Prevent electrical contact between the coils and the armature core.

- Heat dissipation: Allow heat to dissipate from the coils.

9. What are the different types of armature connectors used in DC machines?

- Radial connectors: Extend radially from the armature core.

- Chordal connectors: Connect adjacent coils in a straight line.

- Wave connectors: Connect coils in a zigzag pattern.

10. Explain the importance of proper connector design in armature performance.

- Efficient current transfer: Ensures maximum current flow to the coils.

- Reduced losses: Minimizes resistance and heat losses.

- Mechanical stability: Prevents coil damage due to vibration or impacts.

- Extended lifespan: Proper design and maintenance prolong the life of the armature.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Armature Connector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Armature Connector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Armature Connector is a manufacturing professional who is responsible for assembling various components that create armatures for electric motors or other machinery.

1. Coil Winding

Wind coils of insulated wire around armature cores using specialized machinery.

- Operate winding machines to wrap coils around armature cores.

- Maintain winding parameters to ensure accurate coil placement and alignment.

2. Coil Forming

Shape and form coils into specific configurations using manual tools or automated equipment.

- Bend coils to create the desired shape and dimensions.

- Secure coils in place using epoxy resin or other bonding materials.

3. Armature Assembly

Assemble armatures by connecting coils to the commutator or other electrical components.

- Align and attach coils to the commutator or other electrical components.

- Secure connections using soldering, welding, or other techniques.

4. Testing and Inspection

Conduct tests and inspections on assembled armatures to ensure they meet specifications.

- Perform electrical continuity checks to identify open circuits or shorts.

- Inspect armatures for defects, such as insulation damage or faulty connections.

Interview Tips

To prepare for an interview for an Armature Connector position, it is important to have a strong understanding of the key job responsibilities as outlined above. Additionally, certain interview tips and strategies can help you ace the interview and make a lasting impression on the hiring manager.

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the specific Armature Connector position you are applying for. This will help you understand the company’s mission, values, and the specific requirements of the role. It will also allow you to ask informed questions during the interview, demonstrating your interest and preparation.

2. Highlight Relevant Skills and Experience

During the interview, be sure to emphasize the skills and experience that are most relevant to the Armature Connector position. Focus on your ability to wind coils, form coils, assemble armatures, and conduct testing and inspection procedures. Provide specific examples from your previous experience to demonstrate your proficiency in these areas.

3. Showcase Your Attention to Detail

Armature Connectors must have a keen eye for detail and the ability to work with precision. In the interview, highlight your attention to detail by describing your meticulous approach to quality control and your commitment to ensuring that all components are assembled correctly.

4. Emphasize Your Problem-Solving Abilities

Armature Connectors may encounter unexpected challenges or issues during the assembly process. In the interview, emphasize your problem-solving abilities by describing how you have handled similar situations in the past. Explain your approach to troubleshooting and your ability to find creative solutions to technical problems.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Armature Connector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.